Copolymer film forming resin containing benzoxazine structure and deep UV negativity chemical amplification type photo resist

A technology of film-forming resin and benzoxazine, which is applied in the field of deep ultraviolet negative chemically amplified photoresist composition, and can solve problems such as swelling, film shrinkage, thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

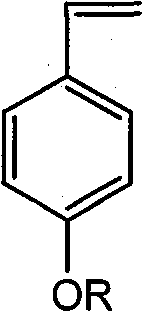

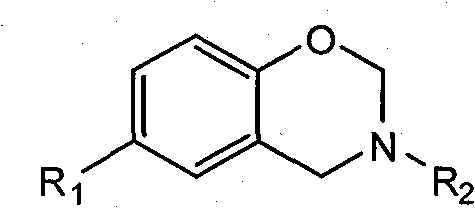

[0090] A copolymer film-forming resin containing a benzoxazine structure, which is prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization:

[0091] 90 grams of p-hydroxystyrene;

[0092] Styrene 5 grams;

[0093] 3-Phenyl-3,4-dihydro-6-(vinyl)-1,3-benzoxazine 7 g.

[0094] The preparation method is: in a 500mL three-neck flask equipped with a mechanical stirrer, condenser, thermometer and nitrogen inlet, add 90 grams of p-hydroxystyrene, 5 grams of styrene, 3-phenyl-3,4-dihydro- 7 grams of 6-(vinyl)-1,3-benzoxazine, 250 grams of tetrahydrofuran, 2 grams of azobisisobutyronitrile, nitrogen flow for 10 minutes under stirring, then heated to 60-70 ° C, and the reaction was refluxed for 4 ~24 hours later, then cooled to room temperature. The polymer solution is precipitated with methanol, then dissolved with acetone, and then precipitated with methanol, repeated 2 to 3 times, and finally vacuum-dried...

Embodiment 2

[0096] A copolymer film-forming resin containing a benzoxazine structure, which is prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization:

[0097] 100 grams of p-acetoxystyrene;

[0098] 6 grams of methyl methacrylate;

[0099] 3-Phenyl-3,4-dihydro-6-(vinyl)-1,3-benzoxazine 20 g.

[0100] The preparation method is: in a 500mL three-neck flask equipped with a mechanical stirrer, condenser, thermometer and nitrogen inlet, add 100 grams of p-acetoxystyrene, 6 grams of methyl methacrylate, 3-phenyl-3, 20 grams of 4-dihydro-6-(vinyl)-1,3-benzoxazine, 250 grams of tetrahydrofuran, 2.6 grams of azobisisobutyronitrile, nitrogen for 10 minutes under stirring, and then heated to 60-70 °C, the reaction was refluxed for 4-24 hours, and then cooled to room temperature. The polymer solution was precipitated with methanol, then dissolved with acetone, and then precipitated with methanol, repeated 2 to 3 time...

Embodiment 3

[0102] A copolymer film-forming resin containing a benzoxazine structure, which is prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization:

[0103] 100 grams of p-acetoxystyrene;

[0104] 10 grams of p-tert-butylstyrene;

[0105] 8 grams of methyl methacrylate;

[0106] 3-Phenyl-3,4-dihydro-6-(vinyl)-1,3-benzoxazine 7 g.

[0107] The preparation method is: in a 500mL three-neck flask equipped with a mechanical stirrer, a condenser, a thermometer and a nitrogen inlet, add 100 grams of p-acetoxystyrene, 10 grams of p-tert-butylstyrene, and 8 grams of methyl methacrylate. gram, 3-phenyl-3,4-dihydro-6-(vinyl)-1,3-benzoxazine 7 grams, tetrahydrofuran 250 grams, azobisisobutyronitrile 1.25 grams, nitrogen flow under stirring 10 minutes, then heated to 60 ~ 70 ° C, the reaction was refluxed for 4 ~ 24 hours, and then cooled to room temperature. The polymer solution is precipitated with methanol, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com