Adhesive mass for nonpolar substrates

A technology for adhesives, pressure-sensitive adhesives, applied in the direction of film/sheet adhesives, adhesive types, hydrocarbon copolymer adhesives, etc., which can solve the damage of cohesion, no improvement in usefulness, etc. problem, to achieve the effect of high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

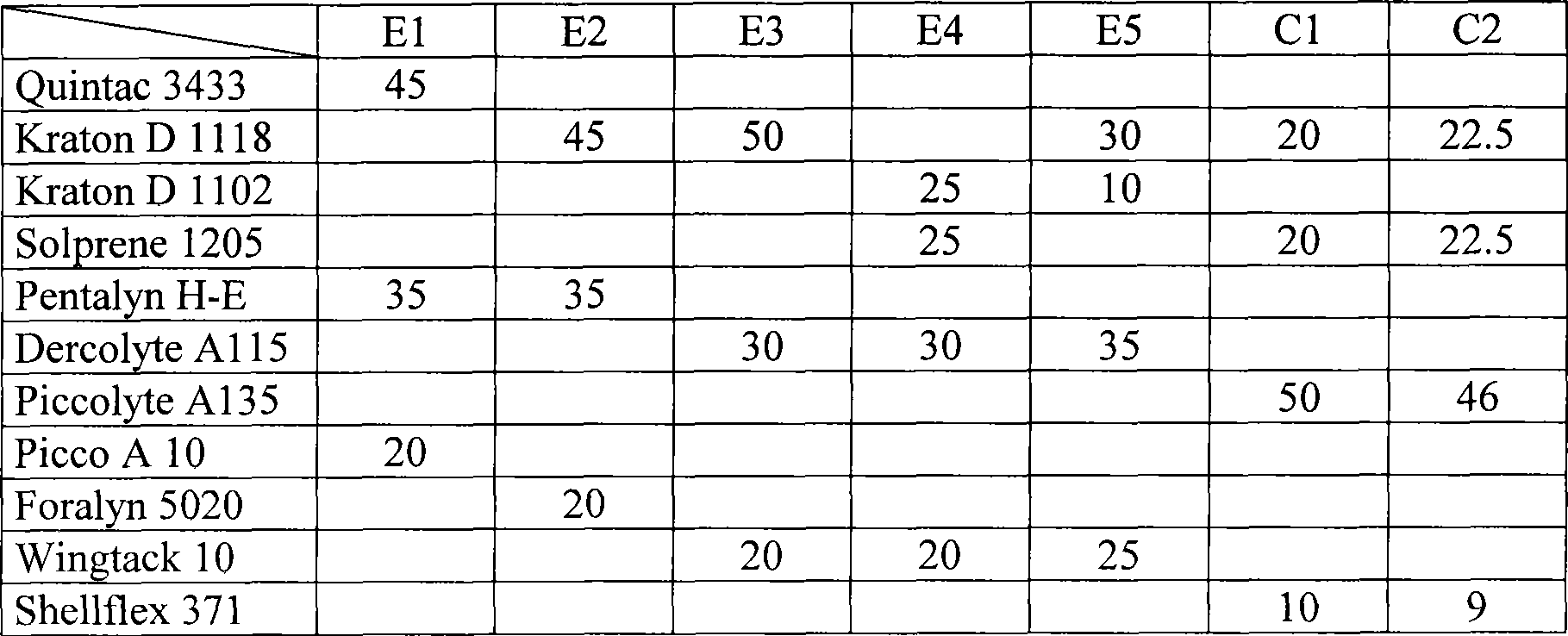

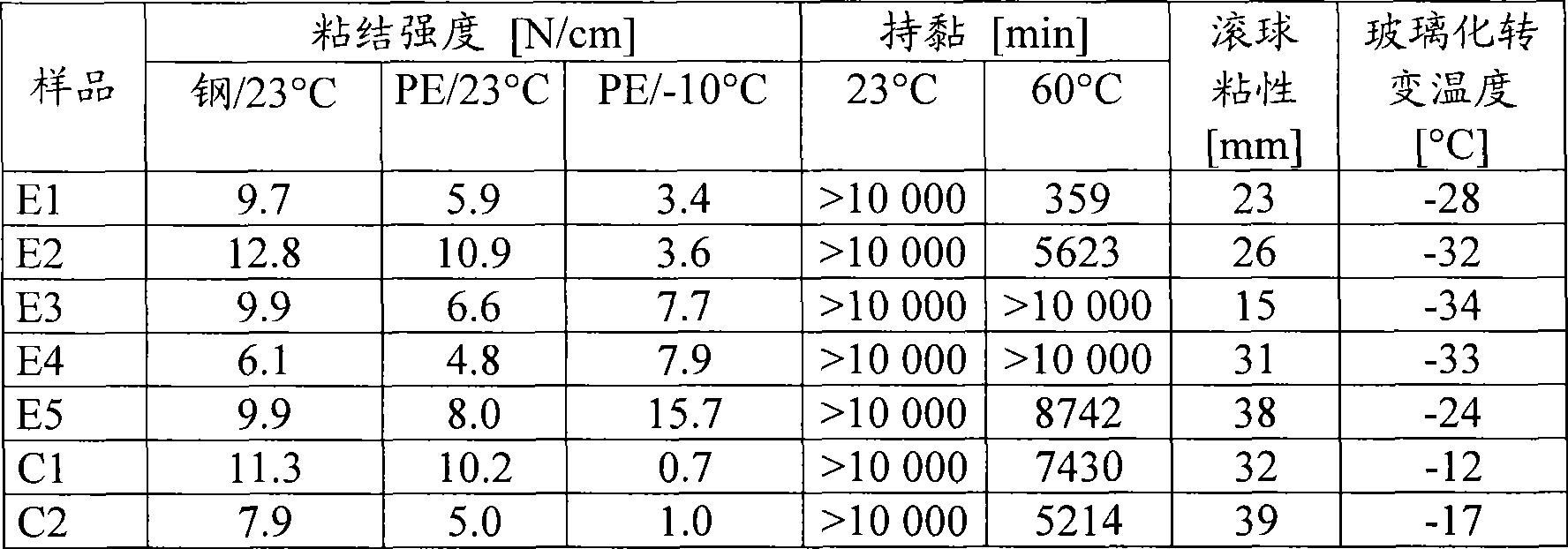

[0067] Further advantages and possibilities for application will emerge from the working examples, which will be described in more detail below.

[0068] To illustrate the general concept of the invention, 5 different PSAs were illustratively prepared, and 2 additional PSAs were prepared as comparative examples (the latter containing components that are liquid at room temperature but cannot be used as tackifier resins). For this purpose, the individual components of the PSA were dissolved in toluene and the solids content of the resulting solution was adjusted to 40% by weight. The solution thus obtained was applied to one side of a polyester film (polyethylene terephthalate with a thickness of 36 μm) using a coating bar, and toluene was removed at 100° C. in the next drying step . A coatweight of 50 g / m was obtained in each case 2 .

[0069] As first block copolymer and as second block copolymer the following commercially available block copolymers were used:

[0070] Qui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com