RMG rail-biting fault diagnosis method based on multi-sensor data amalgamation technology

A technology of fault diagnosis and data fusion, which is applied in the field of rail-mounted lifting equipment and rail locomotives, can solve problems such as wrong judgment results, incompleteness, and less sensor information, and achieve improved service life, reliability, and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

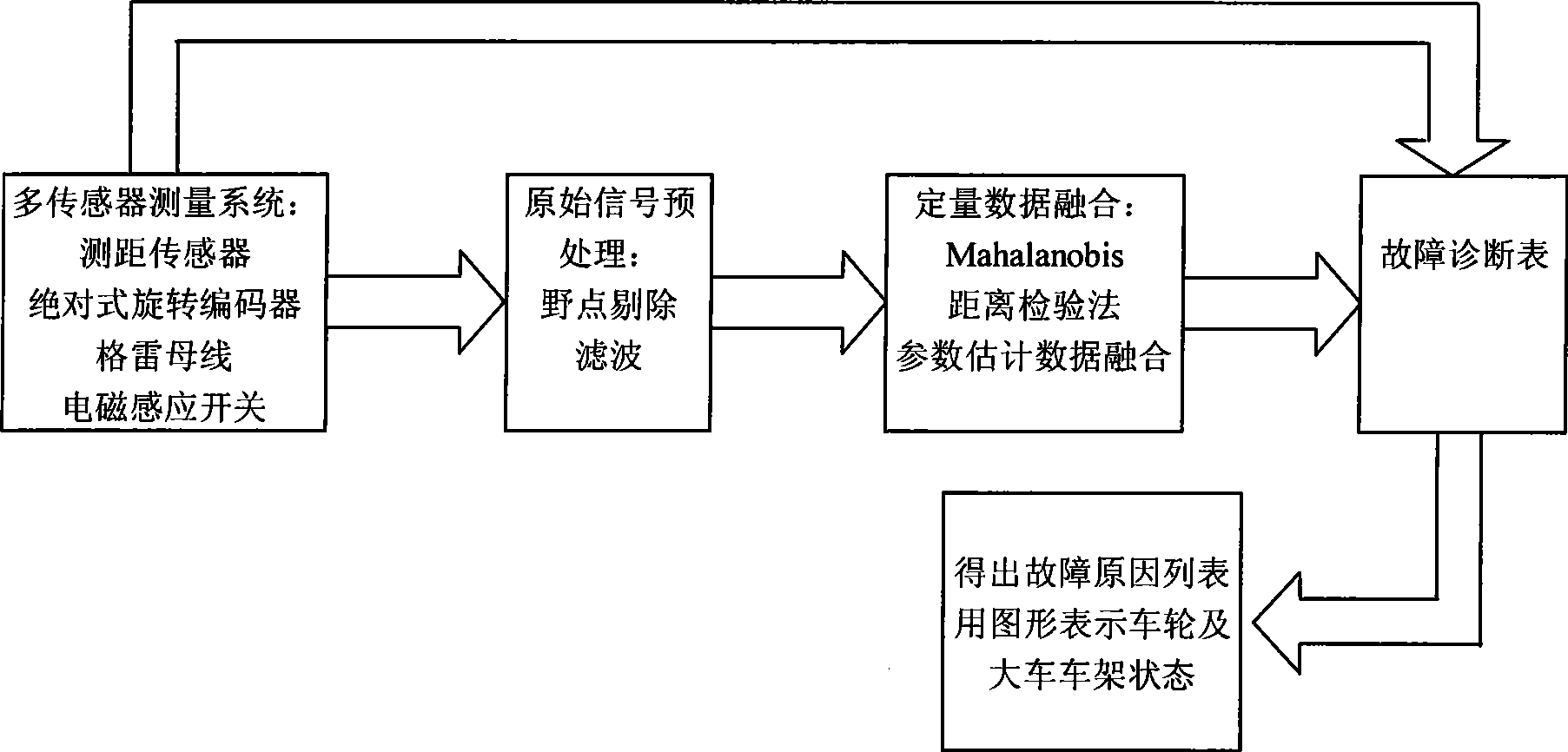

[0024] RMG rail gnawing fault diagnosis flow chart, such as figure 1 shown.

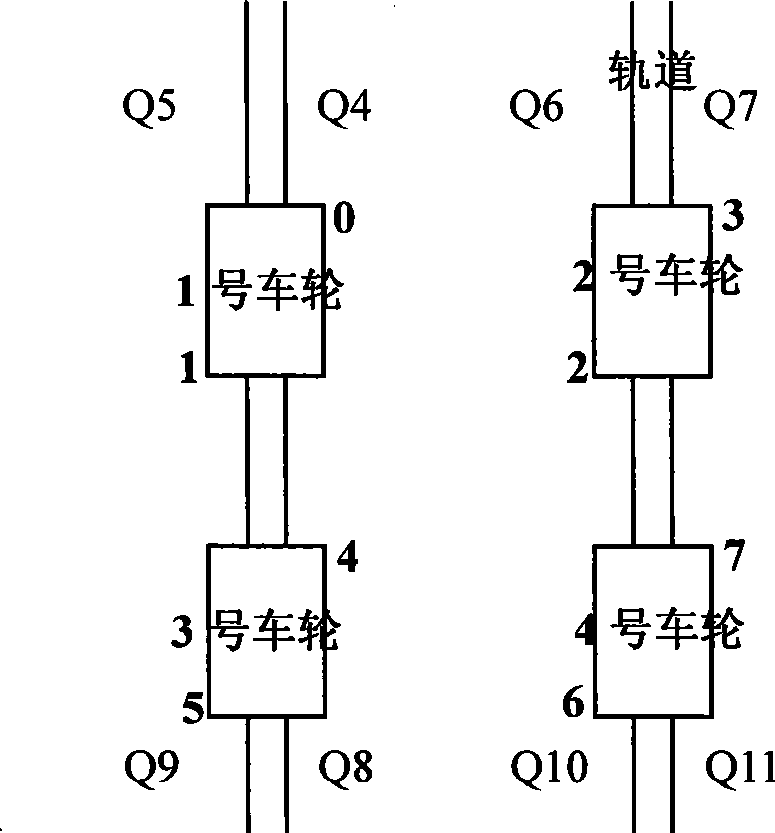

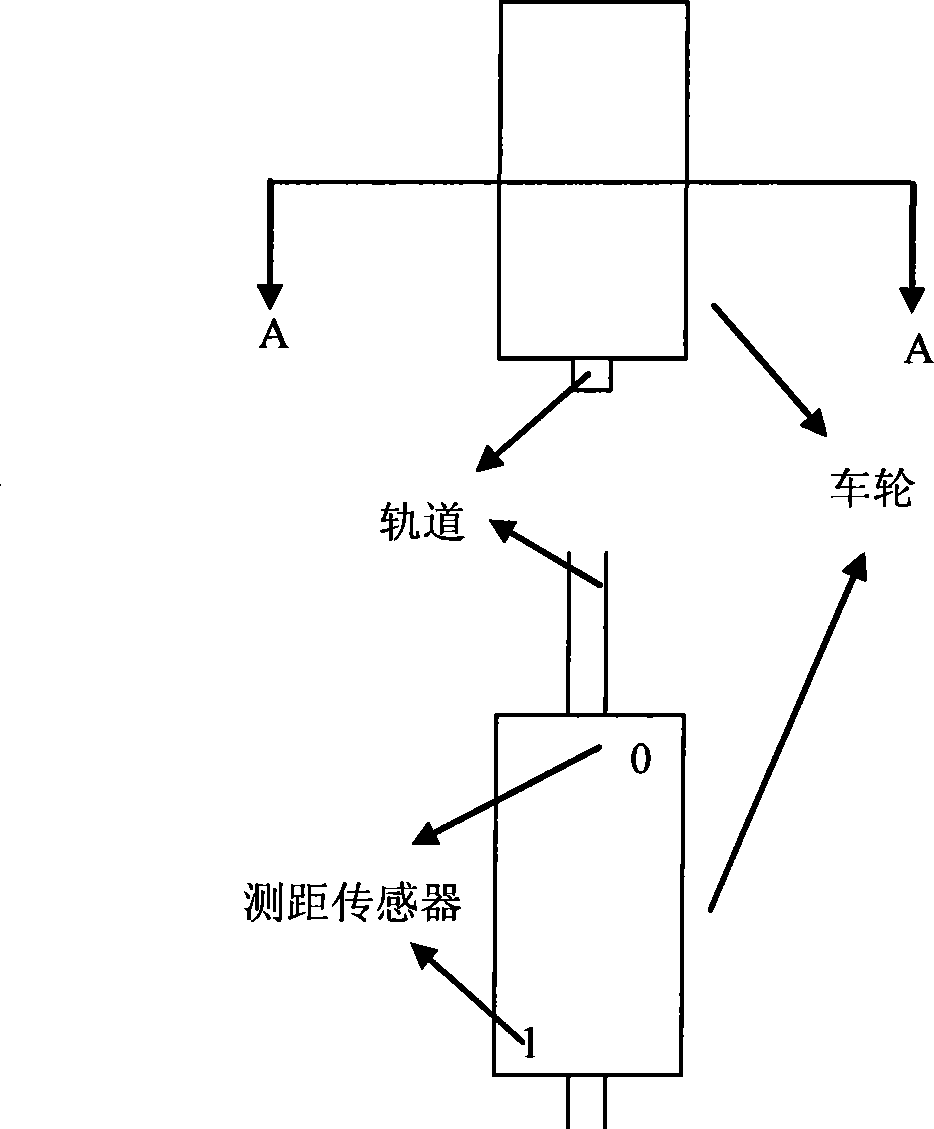

[0025] A distance measuring sensor is installed on the inner and outer sides of the wheels at the four corners of the RMG cart, and the position of each distance measuring sensor is arranged as follows: figure 2 As shown, the specific position of the ranging sensor on a single wheel is as follows image 3 As shown; on both sides of the cart, there is a Gray bus installed parallel to the track to measure the continuous displacement of the cart (the address code generator is installed, and the address signal is transmitted through the core wire of the Gray bus), and the No. 1 and No. 2 wheels on both sides of the cart The antenna box is installed on the top, and the address coding receiver is installed in the control room. The structure diagram of the Gray bus positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com