Method of welding copper aluminum composite material conductor and copper leads

A technology of copper-aluminum composite material and welding method, which is applied in connection, line/collector parts, electrical components, etc., can solve the problems of reduced tensile strength and elongation at wire joints, affecting the mechanical properties and conductivity of wires, etc. , to achieve the effect of preventing electrochemical corrosion and solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

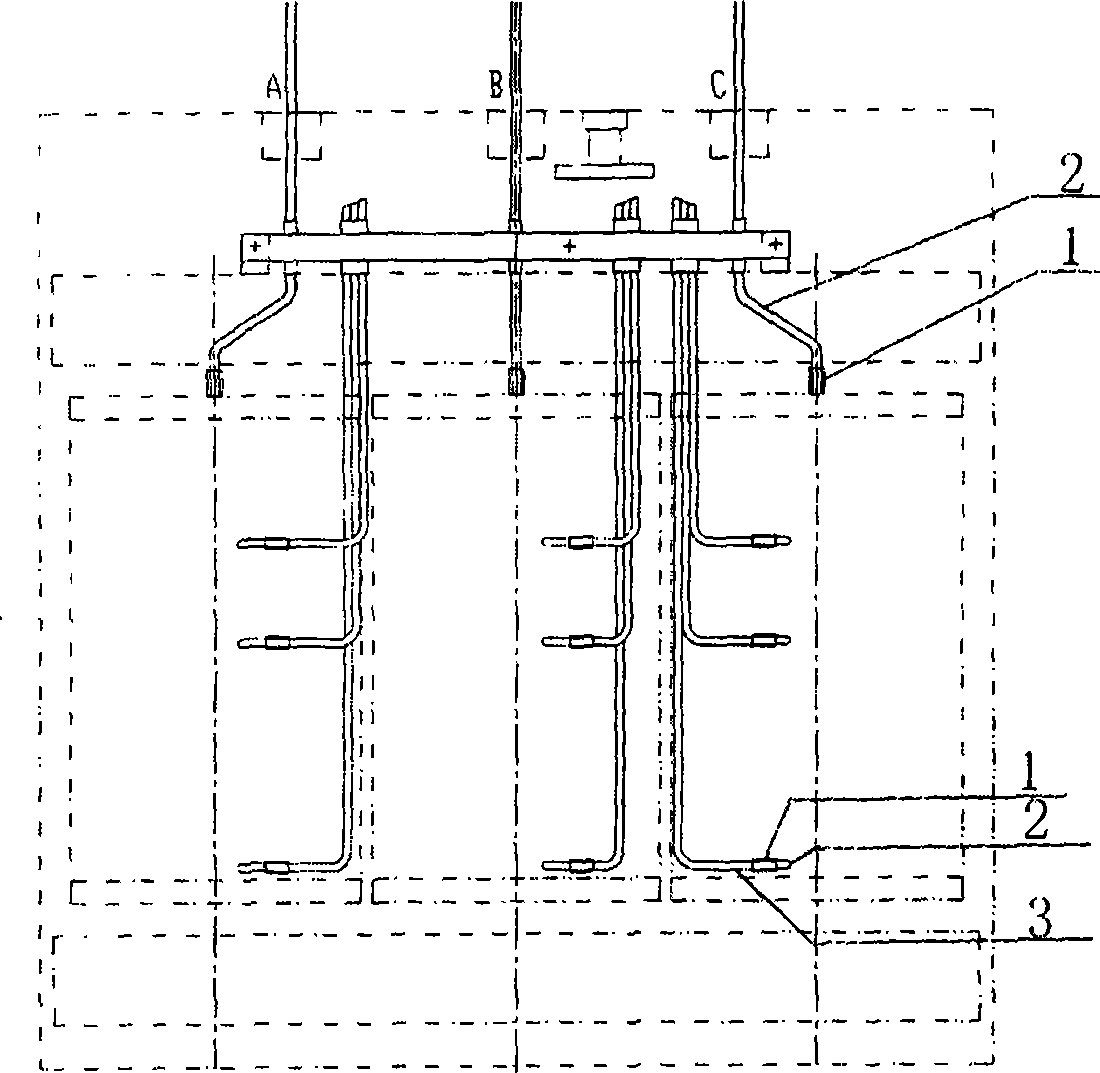

[0022] According to welding method described in the present invention, carry out following steps:

[0023] First, according to the section of the cable or coil outlet, select the appropriate die and wiring bobbin 1, the punch is installed on the piston head of the cylinder, the die is fixed on the frame of the cylinder, and the punch and die correspond to each other. Then the hydraulic cylinder frame is placed outside the wiring barrel 1 or the wiring terminal 3, and its position is such that the distance between the edge of the formed pit and the proximal end of the wiring barrel 1 is 5-8 mm.

[0024] For cold pressure welding of flat wires, the angle between the plane of the pit formed and the width plane of the flat copper wire is controlled at 45 to 75°, and cold pressure welding perpendicular to the large plane of the wire is not allowed.

[0025] Then, control the distance between the edge of the pressure pit to be formed and the end of the terminal bobbin 1 or terminal ...

Embodiment 2

[0027] The above-mentioned cold rolling welding can also be used for the connection between the low-voltage lead wire and the copper bar. Due to the large cross-section of the low-voltage leads, the same steps as in Example 1 are used to cold-press connect the multiple outlets of the same coil to multiple terminals with double holes, and then drill holes in the appropriate positions of the low-voltage copper bars to connect several low-voltage leads. Terminals and copper bars are connected by bolts.

Embodiment 3

[0029] Carry out cold pressure welding to STL series connection terminal, the cold pressure method is the same as embodiment 1. After the combination of A and B, a total of 3 hexagon socket bolts are connected. Two positive and one reverse are required, that is, two hexagon socket bolt heads are on one side, and the other is on the other side. Tighten and tighten.

[0030] Applying the method described in the present invention to weld the copper-aluminum composite wire and the copper lead wire can make the copper-aluminum composite material wire and the copper lead wire firmly butt, and effectively prevent electrochemical corrosion at the interface, so that the copper-aluminum composite material can be welded Wires are used in winding transformer windings and other application fields to provide technical support and solve technical problems in the connection of wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com