Fixing structure of thermostat

A technology of installation structure and thermostat, which is applied in the direction of instrumentation, temperature control, engine cooling, etc., can solve problems such as troublesome operation, damage to the sealing of the joint between the engine main body and the outlet shell, and achieve good operability and simplified insertion the effect of the job

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

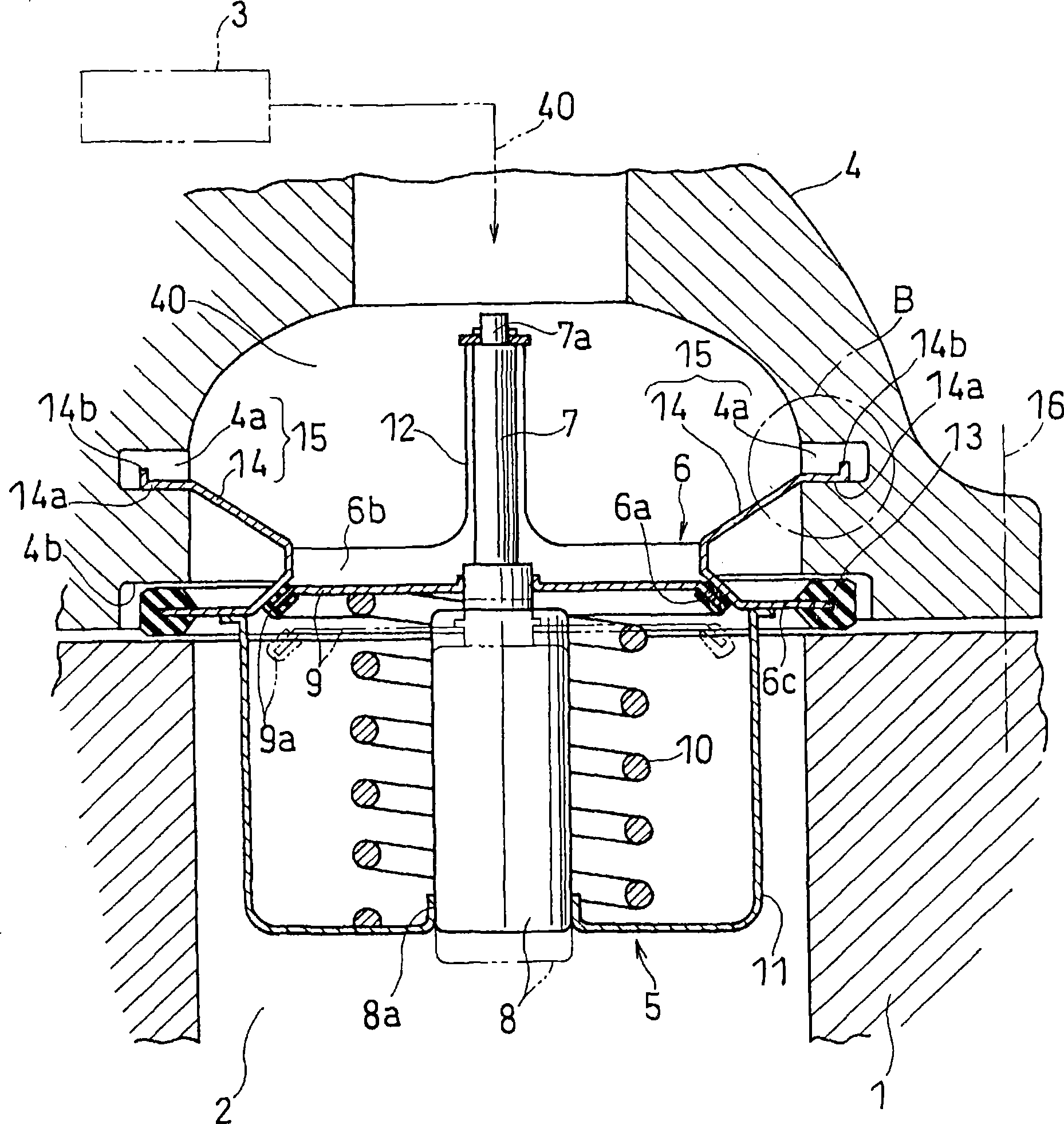

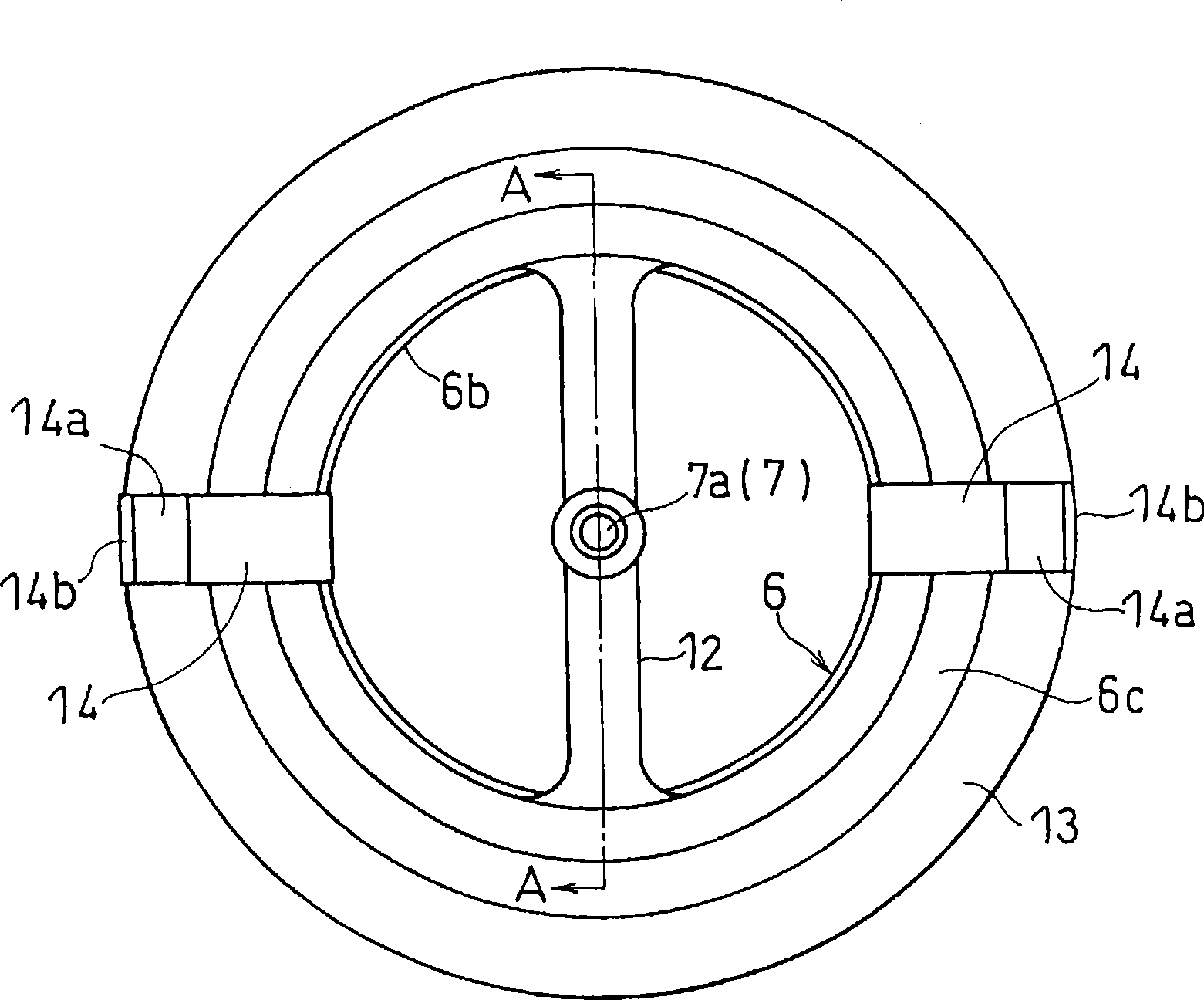

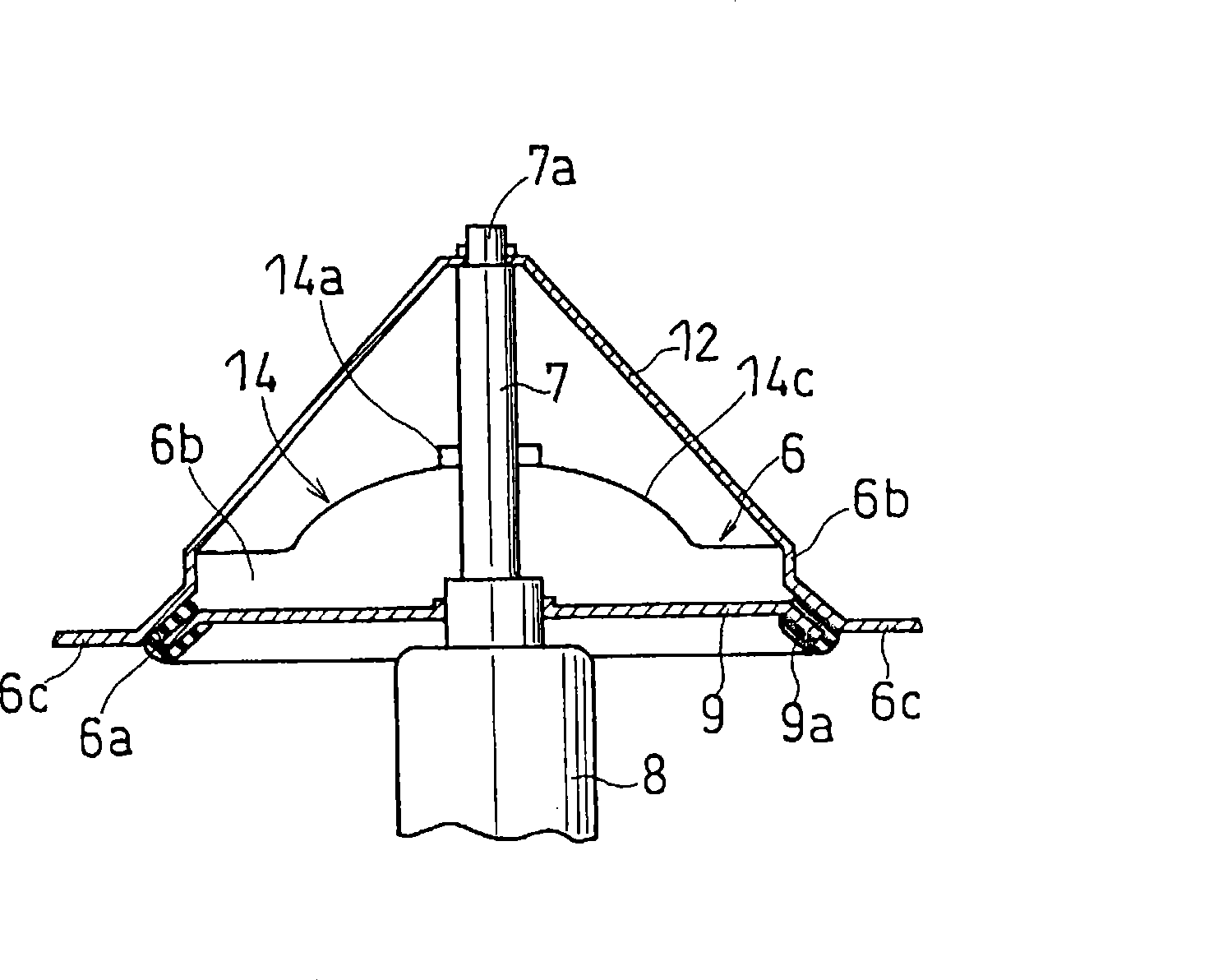

[0061] figure 1 An example of the mounting structure of the thermostat to which the present invention is applied when the internal combustion engine is a water-cooled engine is shown. In the figure, the thermostat 5 is located between the cooling water circulation path 40 and the cooling water flow path 2 of the engine body 1, and the thermostat 5 is used to control the cooling water cooled by heat radiation in the radiator (radiating mechanism) 3. , flows into the cooling water flow path (cooling medium flow path) 2 through the inlet casing 4 constituting a part of the cooling water circulation path (cooling medium circulation path) 40, and the cooling water flow path 2 leads to the engine main body (cylinder head portion) which is the main body of the internal combustion engine. ) 1 water cooling jacket (not shown).

[0062] The thermostat 5 has: an annular support base 6, the inner peripheral portion of which is a valve seat 6a; a valve casing 8, which is provided with a c...

Embodiment 2

[0075] Figure 5 Referring to the second embodiment, the locking tongue 14A constituting the locking mechanism 15 is produced separately from the support base 6 and integrally joined to the flange portion 6 c of the support base 6 . The front side portion 14Aa of the locking tongue piece 14A is bent in the diameter-expanding direction, and the base portion of the locking tongue piece 14A is integrally bonded to the flange portion 6c. This is done by adhesives, riveting, screwing or the like. The illustration shows the joint integration by riveting. In the case of this embodiment, unlike the locking tongue 14 formed by cutting from the support base 6 as in the above-mentioned first embodiment, there is an advantage that there are few restrictions on the formation position of the locking tongue 14A. The other configurations are the same as above, and thus the same reference numerals are assigned to the same parts and their descriptions are omitted.

Embodiment 3

[0077] Figure 6 shows the third embodiment, Figure 7 (a), (b), and (c) show modifications thereof. The thermostat locking mechanism 15 of this embodiment has: at least one pair of locking tongue pieces 14C, and a rising portion (becoming a part of the vertical portion 6b connected to the inner diameter side of the valve seat 6a) 14Ca standing up from the support base 6 And its front side part is constituted by a bent reed part 14Cb; the locking step part 4c is formed on the inner wall surface of the cooling water circulation path 40 of the inlet housing 4, and is elastically connected with the reed part 14Cb of the locking tongue 14C The thermostat 5 can be elastically installed and supported.

[0078] Figure 6 The illustrated locking tongue 14C is formed by cutting from a 180-degree facing position of the support base 6 (a position perpendicular to the restriction frame 12 ), and the spring part 14Cb is curved in a radially expanding direction to form a "U" shape. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com