Tenon joint type spatial mesh structure

A space grid, tenon-joint technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of inability to apply a large number of space frame structures, high construction difficulty, protracted time, etc., to achieve water conservation auxiliary facilities, Simple and fast construction, reducing the effect of auxiliary facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

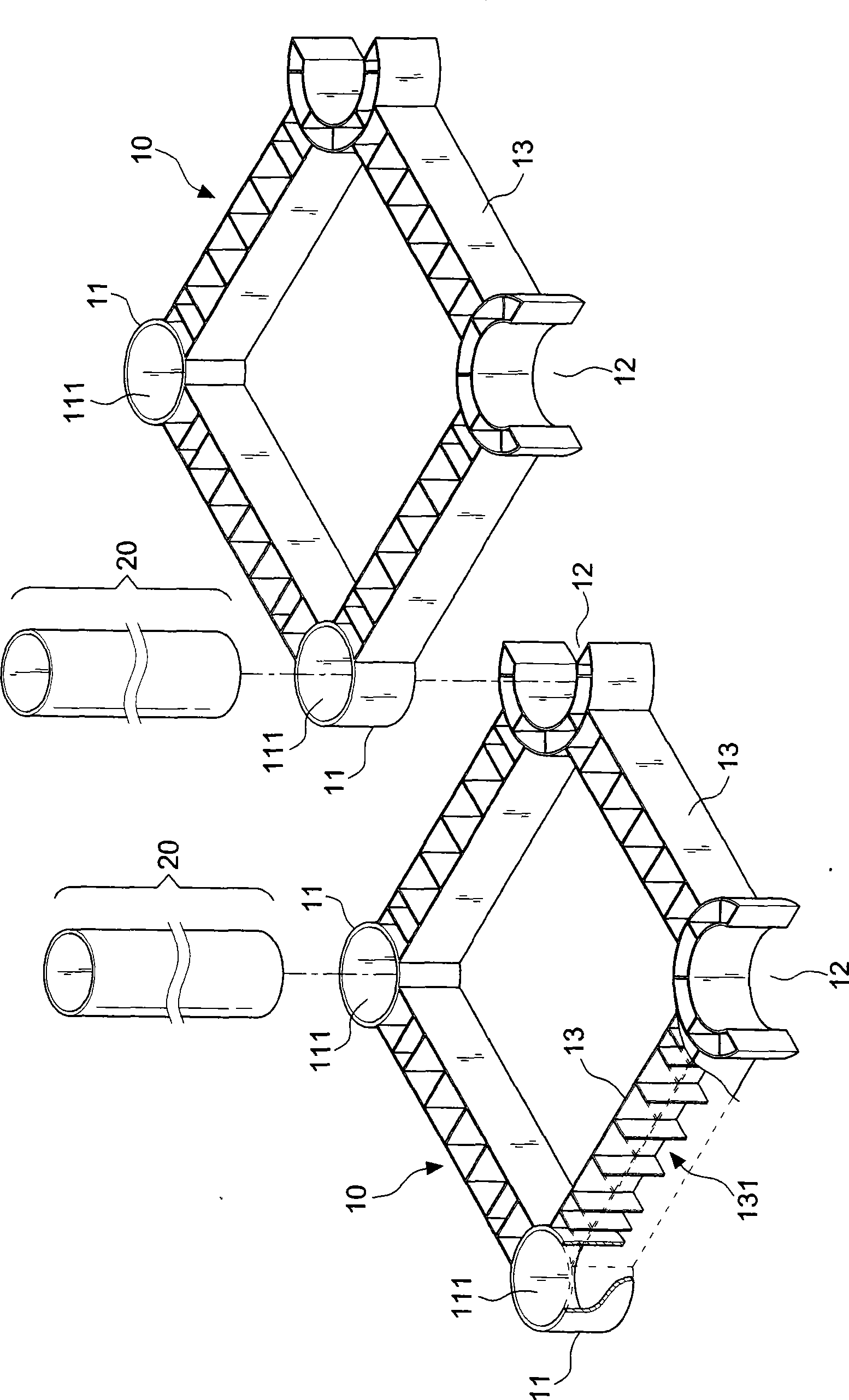

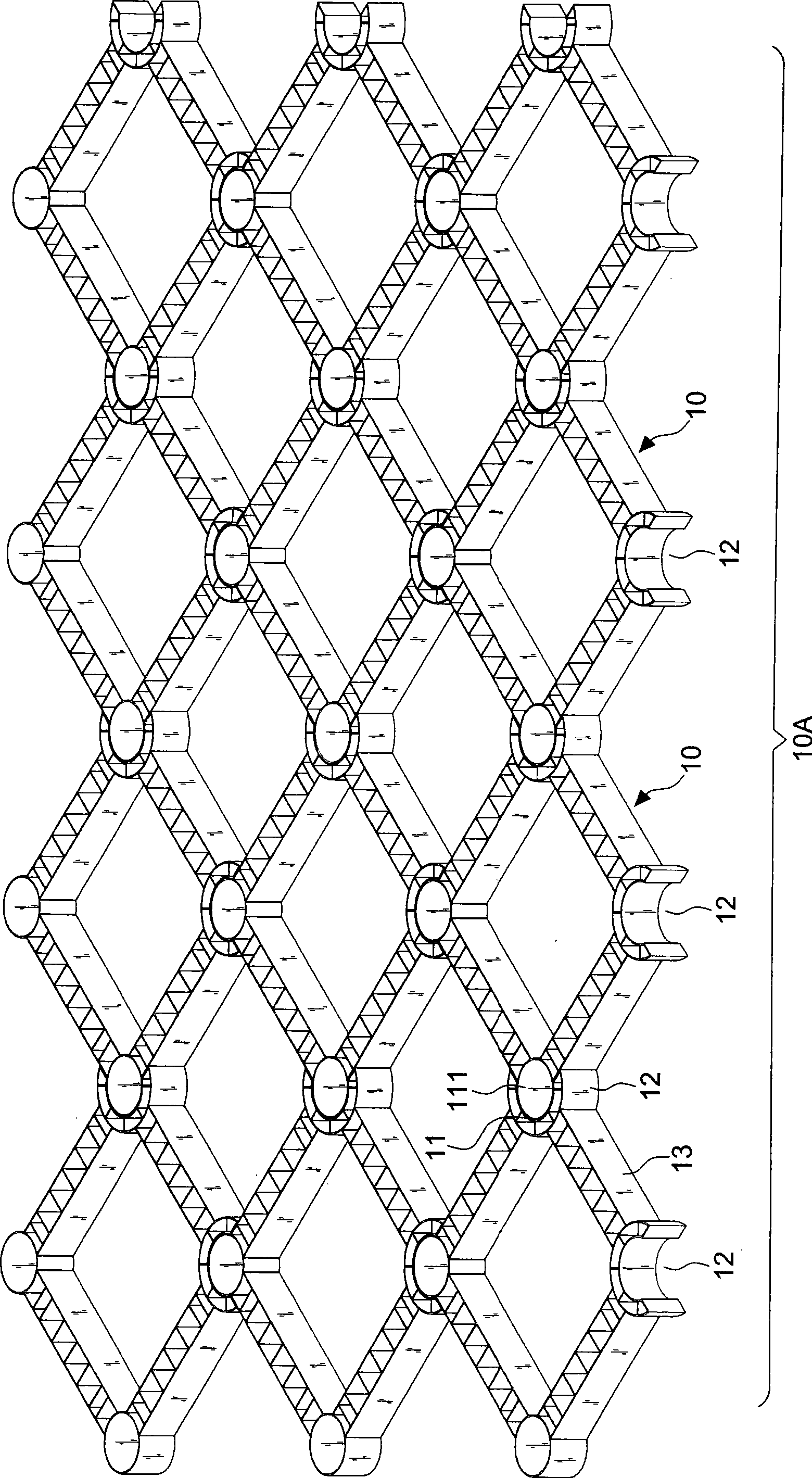

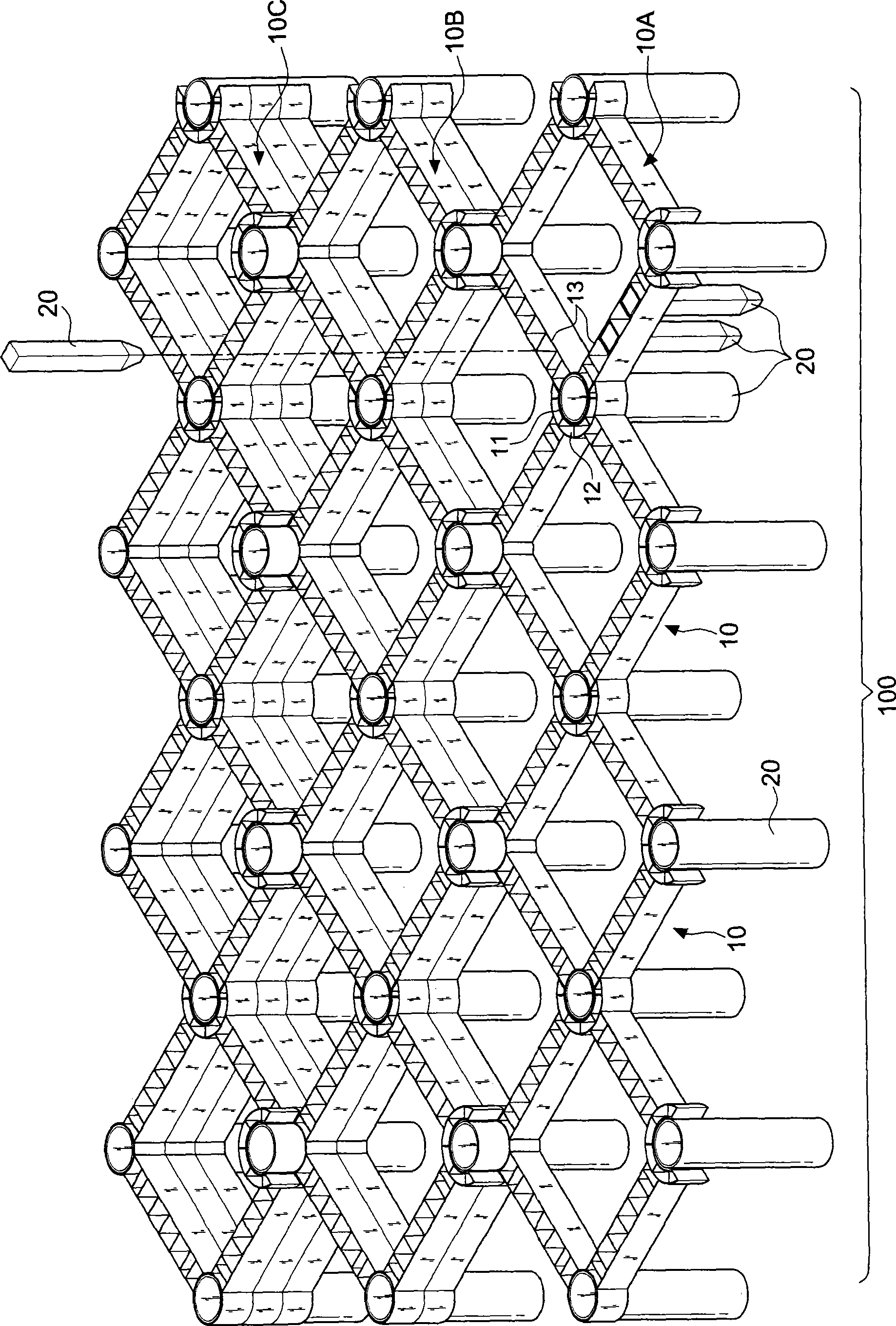

[0069] First, see Figure 1 ~ Figure 3 As shown in the first feasible embodiment of the present invention, it includes a predetermined number of grid units 10 and a certain number of binding columns 20; wherein

[0070] The grid unit 10 is preferably a modular body made of light-weight and high-strength resin-based composite materials, but is not limited thereto, such as metal-based, inorganic non-metallic composite materials, and plasticized materials. It can also be used to make grid units of lightweight hollow members. And there are two or more protruding and recessed tenons 11 and slots 12 on each side respectively. The tenons 11 and the slots 12 are structural shapes of corresponding tenons and grooves. The light hollow member Between the grid units 10 , the protruding tenons 11 are respectively inserted into adjacent and corresponding grooves 12 for mortise assembly and are connected to each other, so as to form a planar layer 10A of a predetermined frame structure.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com