Self-circulation jet agitation device for slurry in flue gas desulfurization slurry pool

A desulfurization slurry and slurry tank technology, which is applied in transportation and packaging, mixers, fluid mixers, etc., can solve the problems of difficult slurry stirring effectively, increased energy consumption in stirring operation, and increased initial investment in the stirring system. Increased reliability and operational efficiency, reduced investment and operational energy consumption, and reduced maintenance effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

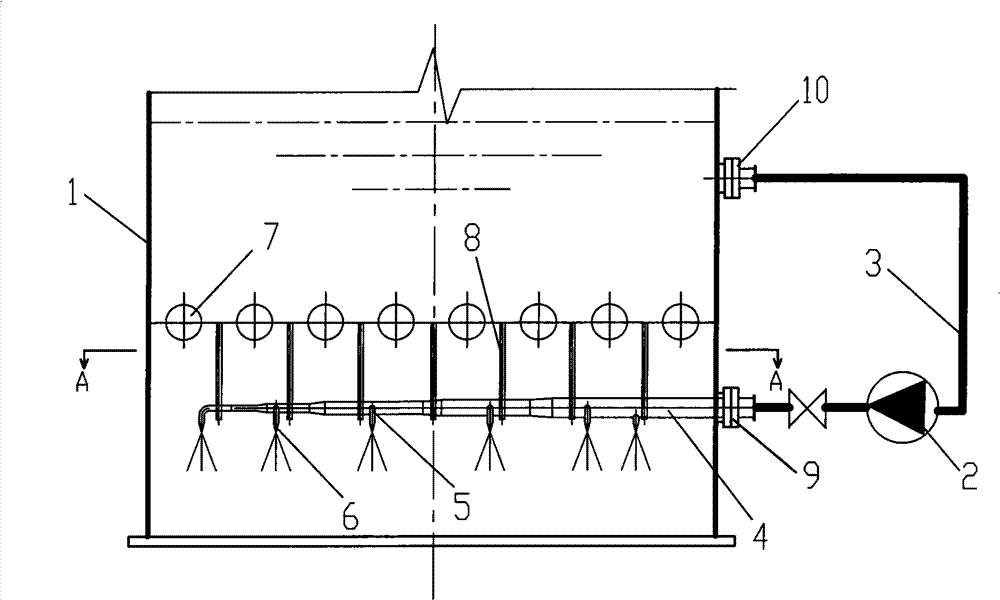

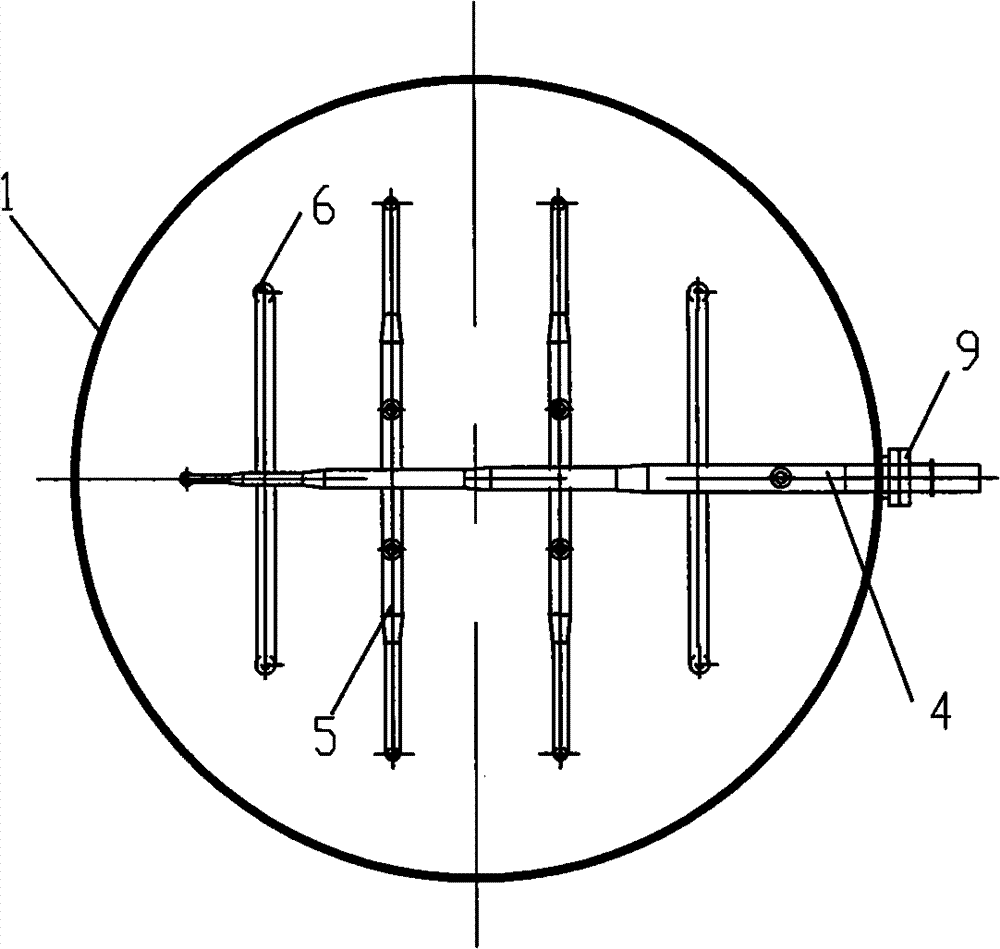

[0015] refer to figure 1 , 2 , the invention of this embodiment includes a slurry tank 1, a slurry pump 2, a circulating slurry main pipe 3, a spray slurry main pipe 4, a spray slurry branch pipe 5, a slurry nozzle 6, a pool separator 7, a bracket 8, a first flange 9, a second Flange10. The slurry pool 1 is a cylindrical shell, and the pool separator 7 is a tube array plane arranged at a certain interval by several hollow circular tubes, supported by the shell side of the slurry pool 1, installed inside the slurry pool 1, and the slurry The tank 1 is divided into upper and lower spaces. There are round holes on the sides of the upper space and the lower space of the slurry tank 1, and they are seamlessly welded with the second flange 10 and the first flange 9 respectively, and the slurry main pipe is sprayed. 4 Installed in the lower space of the slurry tank 1, its inlet is connected to the outlet of the slurry pump 2 outside the slurry tank 1 through the first flange 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com