Method for preparing straw raw material of MDI glue straw artificial board and production line

A technology for wood-based panels and straws, which is applied in the processing field of wood or similar materials, can solve the problems of increasing investment in plant equipment, increasing investment in equipment management and maintenance, and repairing, shortening drying time, and improving fine crushing. effect, effect-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

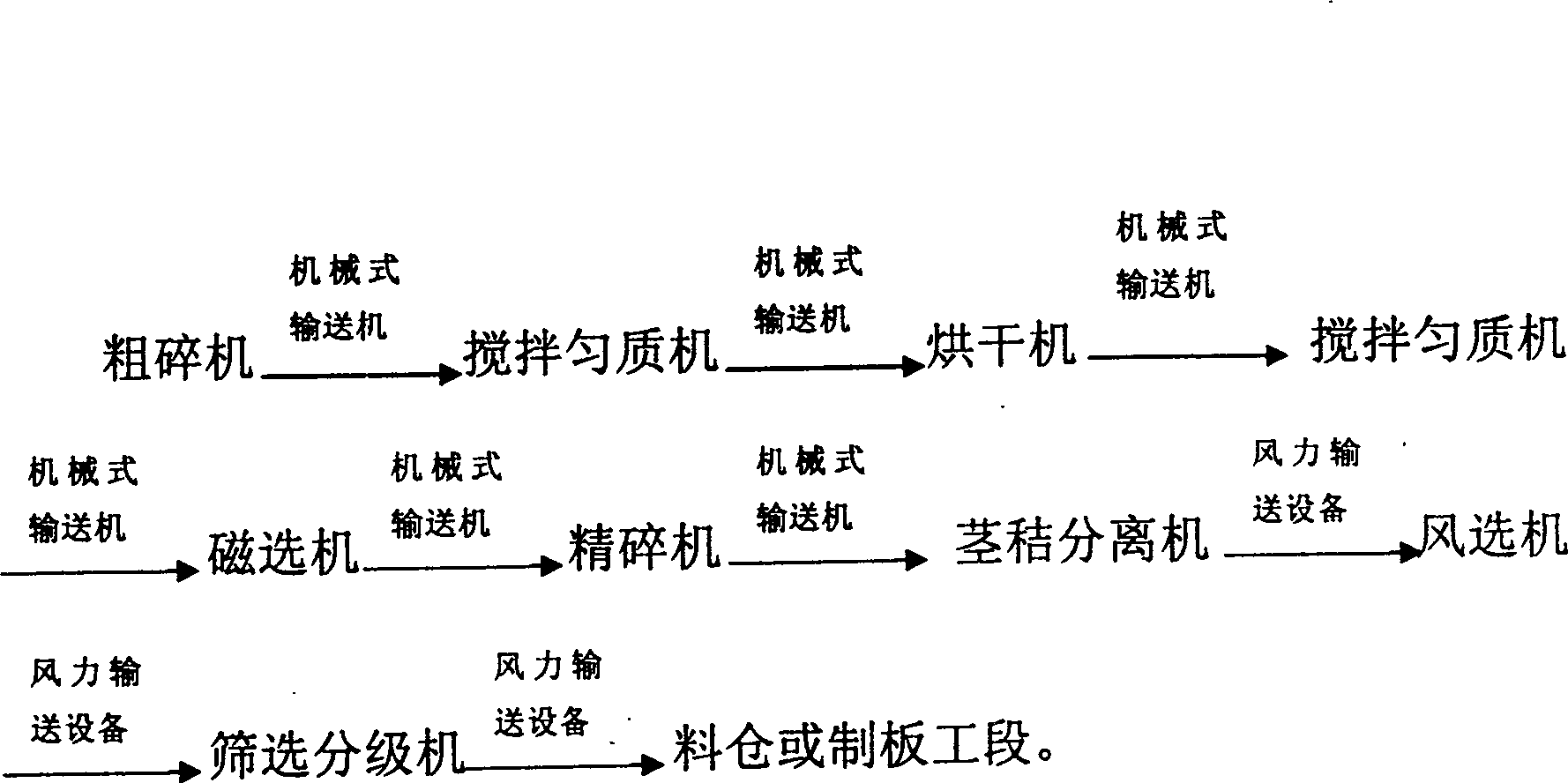

[0013] The straw raw material preparation method of the MDI glue straw artificial board of the present invention comprises the coarse crushing, drying, homogenization, magnetic separation, fine crushing and classification procedures of the existing straw raw material preparation method, but its homogeneous procedure needs to be The drying process is carried out twice before and after, and after fine crushing, the separation of stems and straws and air separation are carried out in turn, and then they are classified. The straw materials after classification can be stored in advance or directly sent to board making. The procedure is as follows:

[0014] Fine crushing, homogenization, drying, homogenization, magnetic separation, selection, stem and straw separation, winnowing separation, grading, storage.

[0015] According to above-mentioned technological process, the production assembly line that the present invention uses and operating process are as follows (referring to figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com