Dormer window sunshading board of motor vehicle

A technology for sun visors and motor vehicles, which is applied to windows, vehicle parts, windshields, etc. It can solve the problems of cumbersome processing technology, large running resistance, and complicated mechanism, and achieve the effects of simple and comfortable appearance, weight reduction, and quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

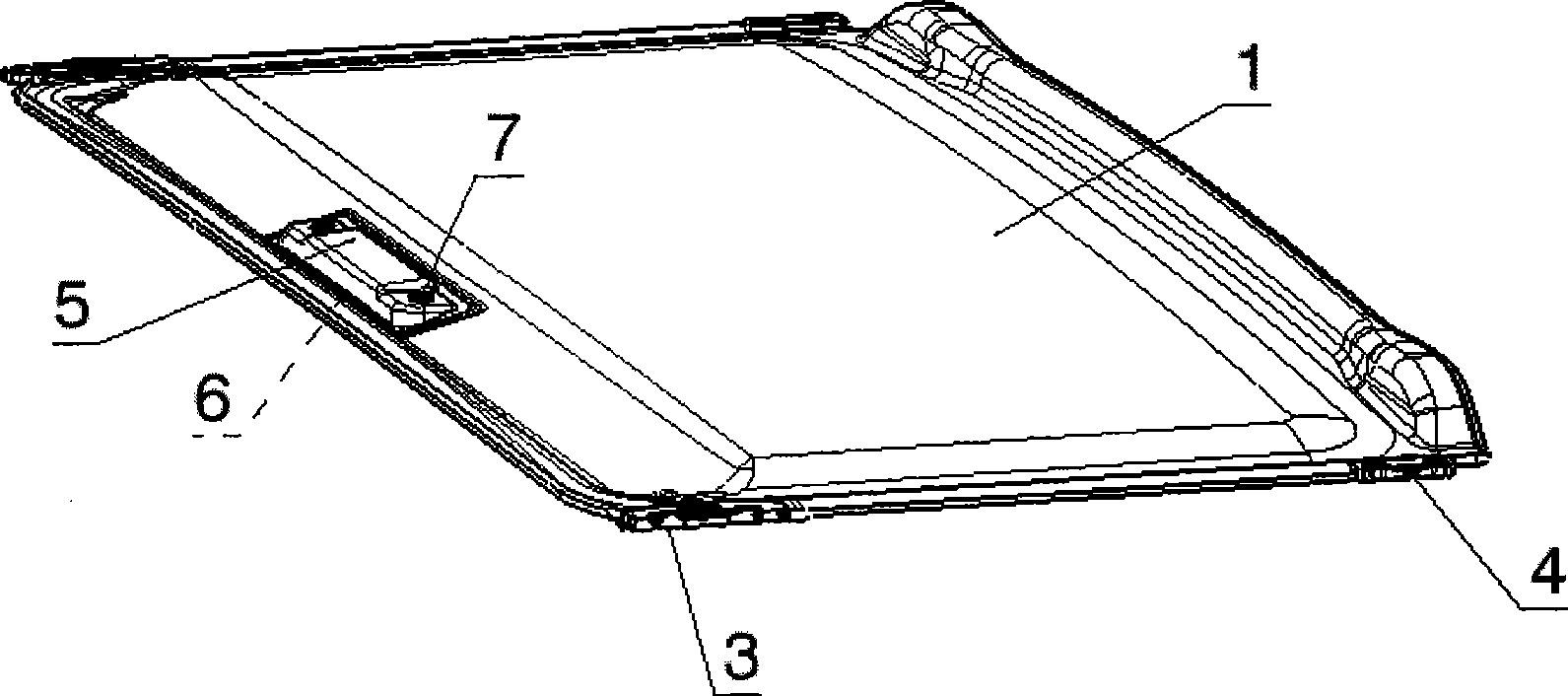

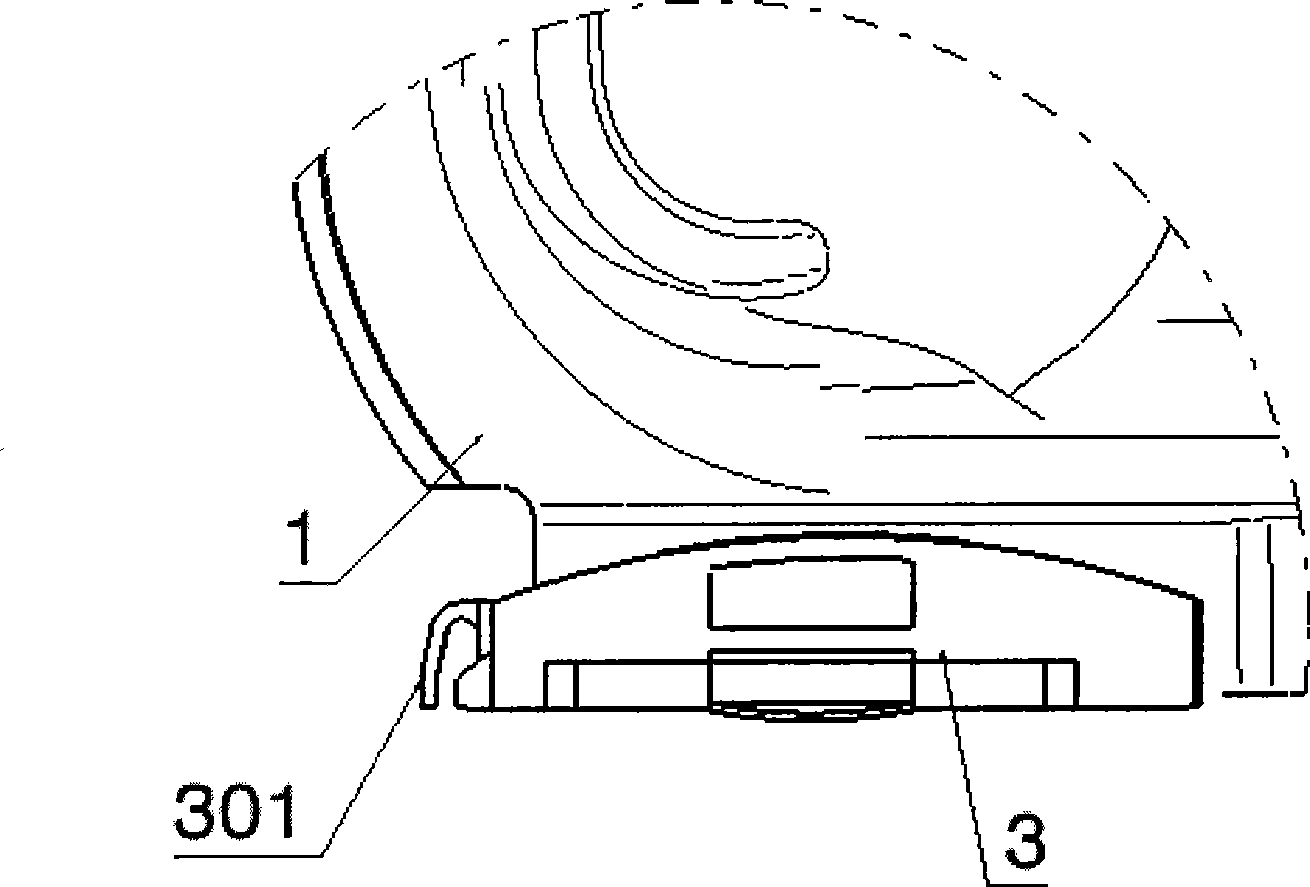

[0027] Such as figure 1 As shown, a motor vehicle sunroof sunshade includes a plate body 1, and the feature is that the plate body 1 is a composite layer.

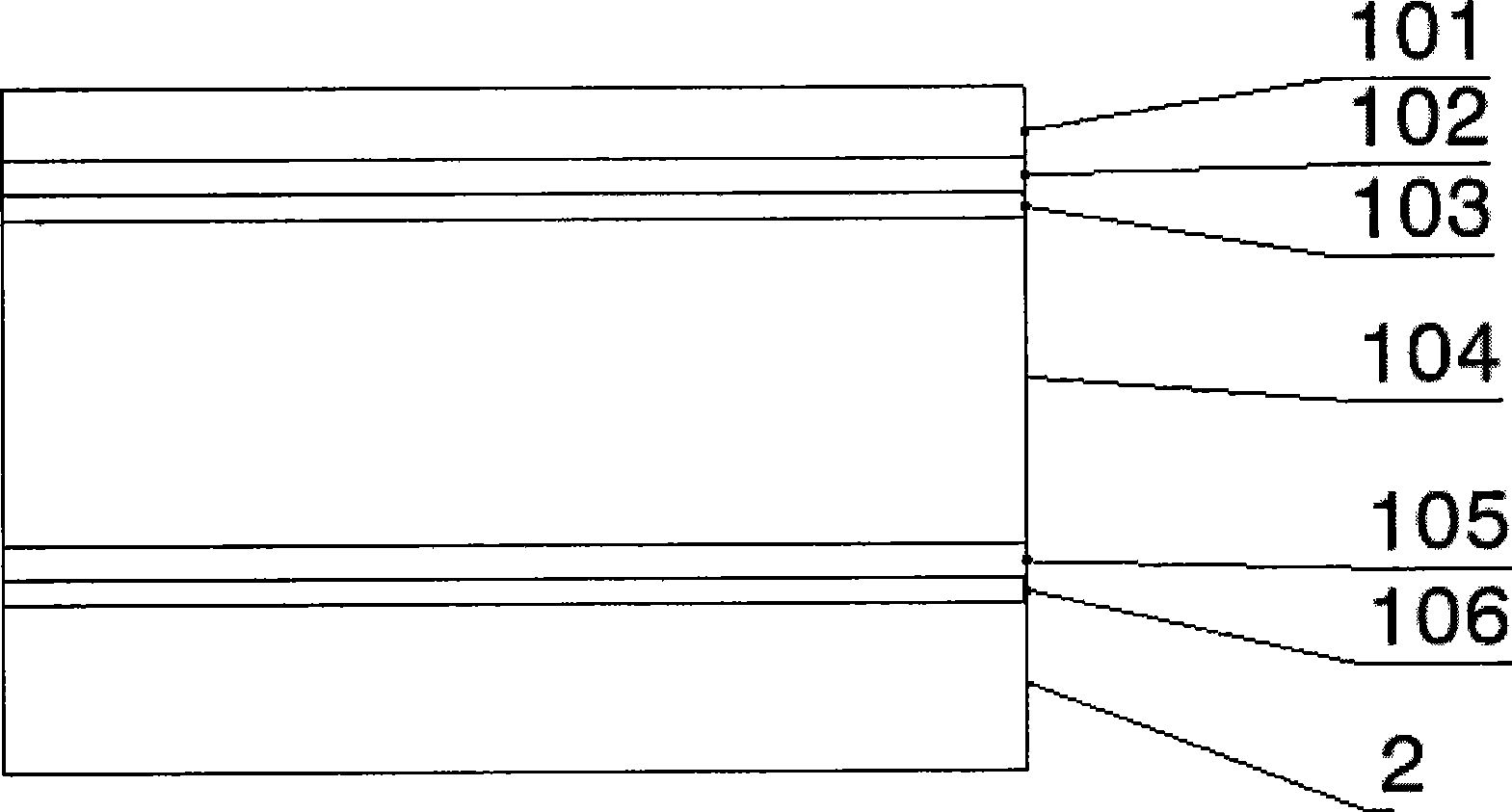

[0028] Such as figure 2 As shown, the board body 1 includes a cloth layer 101, a first glue layer 102, a first glass fiber layer 103, a foam composite material 104, a second glass fiber layer 105, a second glue layer 106 and a fabric layer from top to bottom. Layer 2.

[0029] Wherein, the cloth layer 101 can be selected to have a cloth with an ultraviolet shielding coating, which can simultaneously shield ultraviolet rays and decorate the appearance.

[0030] Wherein, the first glue layer 102 and the second glue layer 106 are composed of a kind of glue, which are used to enhance the strength of the board body 1, and are used to bond the cloth layer 101 and the first glass fiber layer 103, and the second glass fiber layer 103 respectively. Fiber layer 105 and fabric layer 2.

[0031] Wherein, the first glass fiber lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com