Preparation of hollow mesoporous silicon dioxide sphere with continuously variable cavity diameter

A technology of mesoporous silica and silica spheres, applied in the field of inorganic mesoporous materials, can solve the problems of large diameter of spheres and limited application, and achieve the effect of increasing storage capacity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

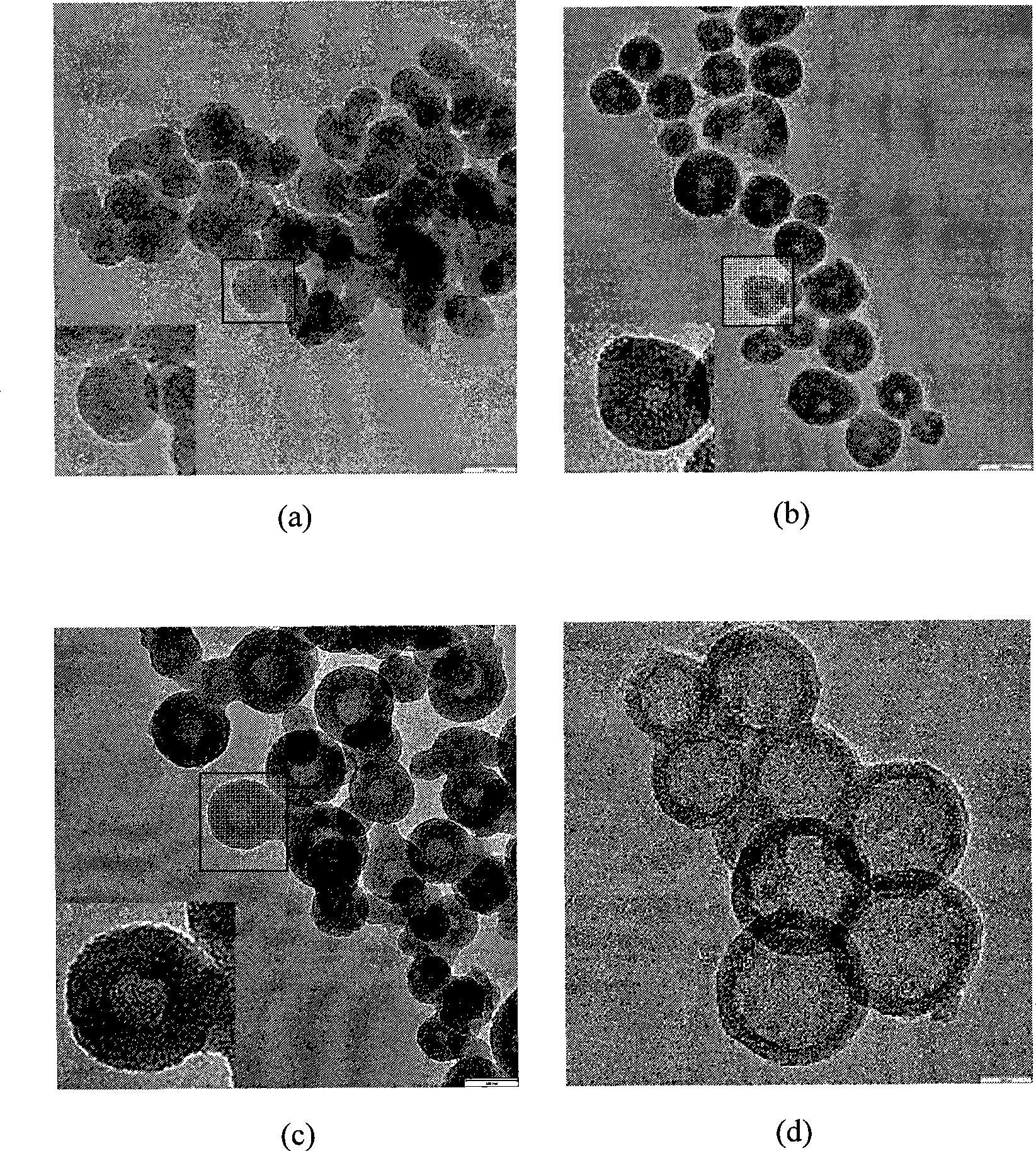

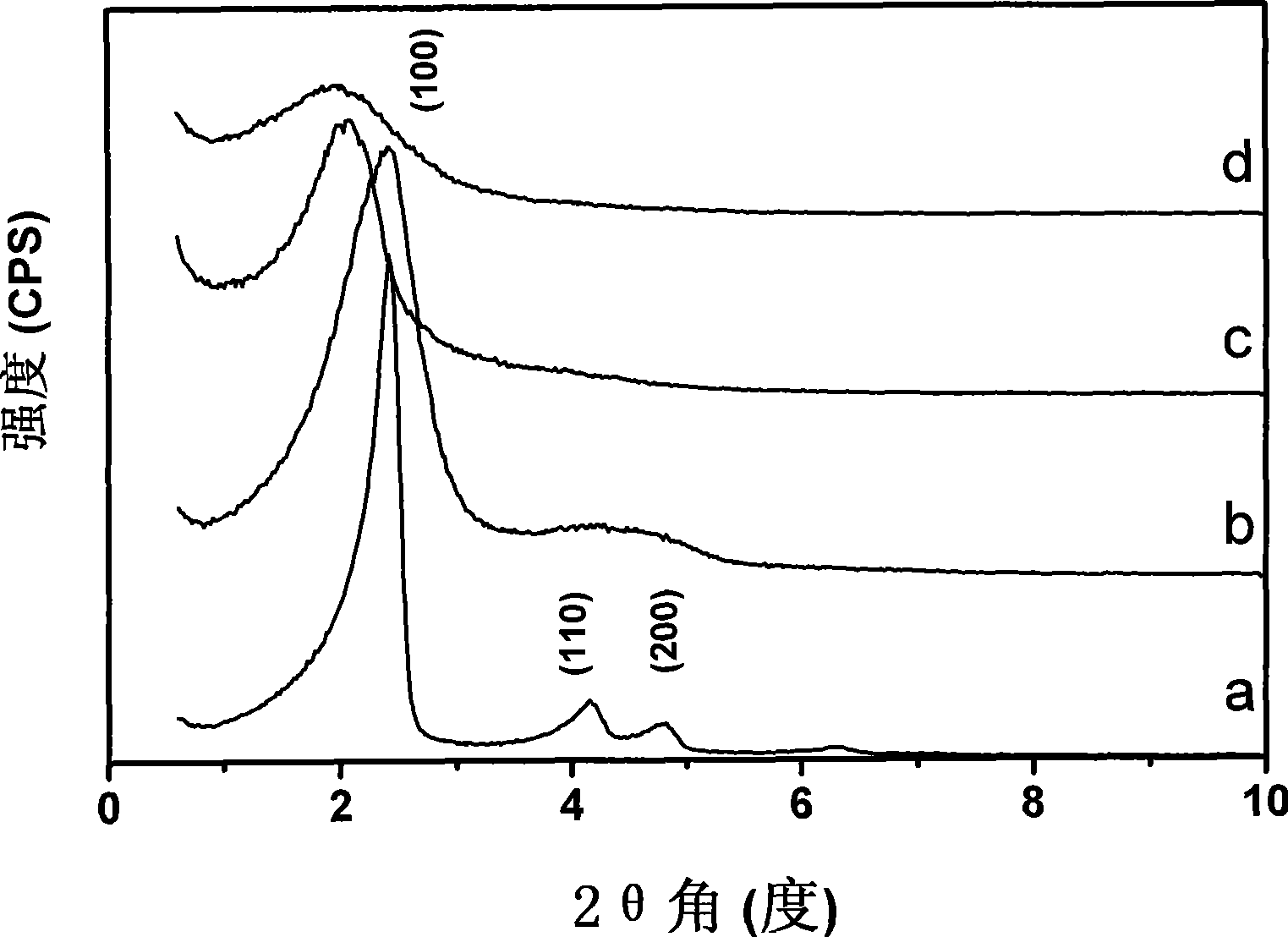

[0019] Dissolve 0.1g of cationic surfactant cetyltrimethylammonium bromide (CTAB) and 3ml of tetraethyl orthosilicate (TEOS) in 12ml, or 20ml, or 30ml, or 50ml of ethanol solution, stir well, Pour quickly into 200ml of ammonia solution with a concentration of 0.2M. Stirring was continued for 5 minutes and then stopped to obtain white flocs. The precipitate is filtered out and calcined, the heating rate is 2°C / min, and the temperature is kept at 600°C for one hour to obtain a cavity diameter of 0nm (such as figure 1 (a)), or 15nm (such as figure 1 (b)), or 50nm (such as figure 1 (c)), or 300nm (such as figure 1 (d)) Hollow mesoporous silica spheres. The thickness of the spherical wall is in the range of 25-50nm, and the diameter of the mesopores on the spherical wall is 2.5-3.2nm. The two-dimensional hexagonal mesopores are arranged perpendicular to the surface of the spherical wall. The SAXRD of the four samples showed that the two-dimensional hexagonal symmetry of the m...

Embodiment 2

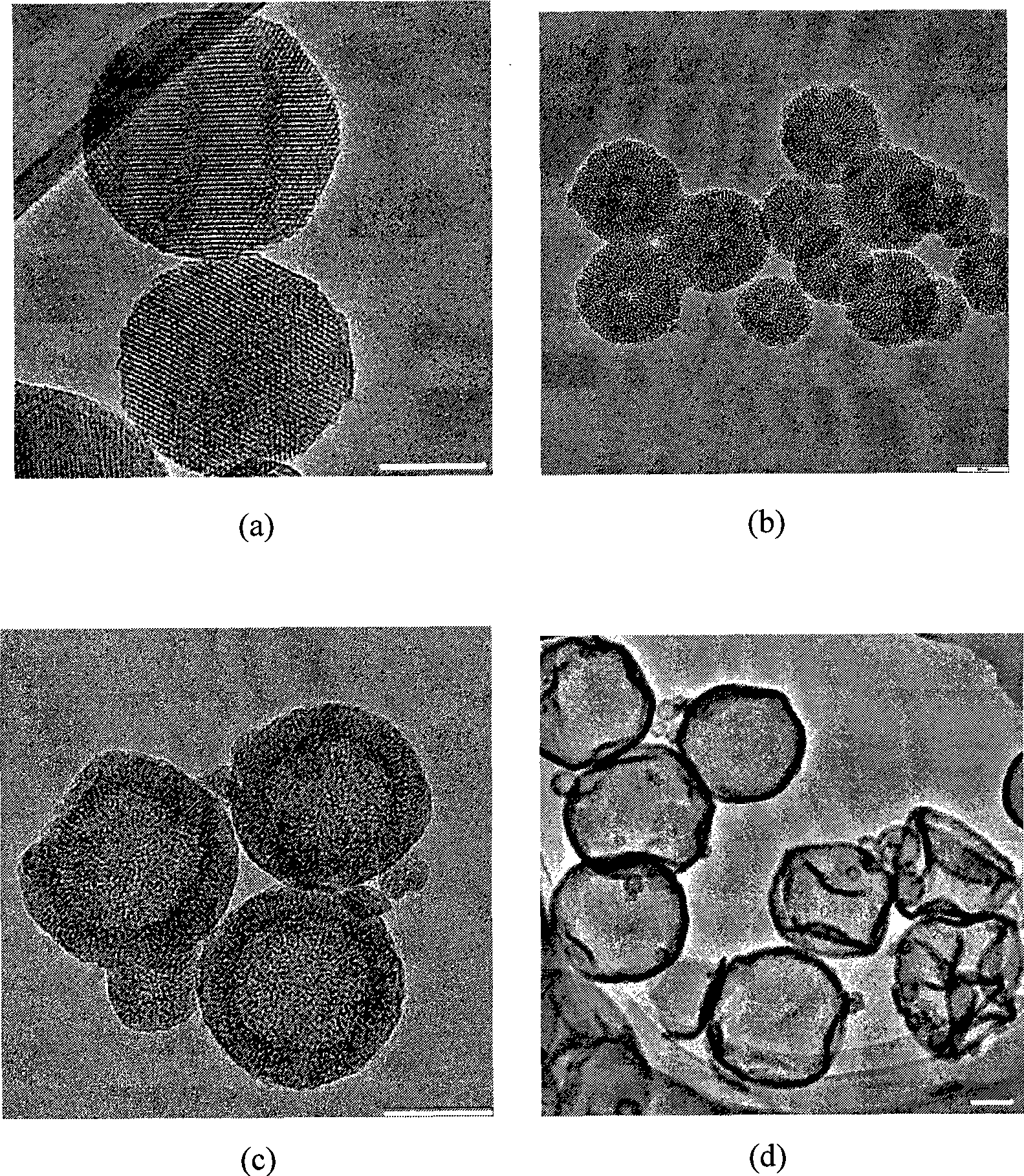

[0021] Dissolve 1 g of cationic surfactant dodecyltrimethylammonium chloride (DTACl) and 9 ml of tetraethyl orthosilicate (TEOS) in 15 ml, or 25 ml, or 40 ml, or 60 ml of ethanol solution, stir thoroughly, and quickly Pour it into 200ml of ammonia solution with a concentration of 0.4M. Stirring was continued for 5 minutes and then stopped to obtain white flocs. The precipitate is filtered out and calcined, the heating rate is 2°C / min, and the temperature is kept at 600°C for one hour to obtain a cavity diameter of 0nm (such as figure 2 (a)), or 15nm, (eg figure 2 (b)) or 50nm (such as figure 2 (c)), or 300nm (such as figure 2 (d)) Hollow mesoporous silica spheres. The thickness of the spherical wall is in the range of 25-50nm, and the diameter of the mesopores on the spherical wall is 2.5-3.2nm. The two-dimensional hexagonal mesopores are arranged perpendicular to the surface of the spherical wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com