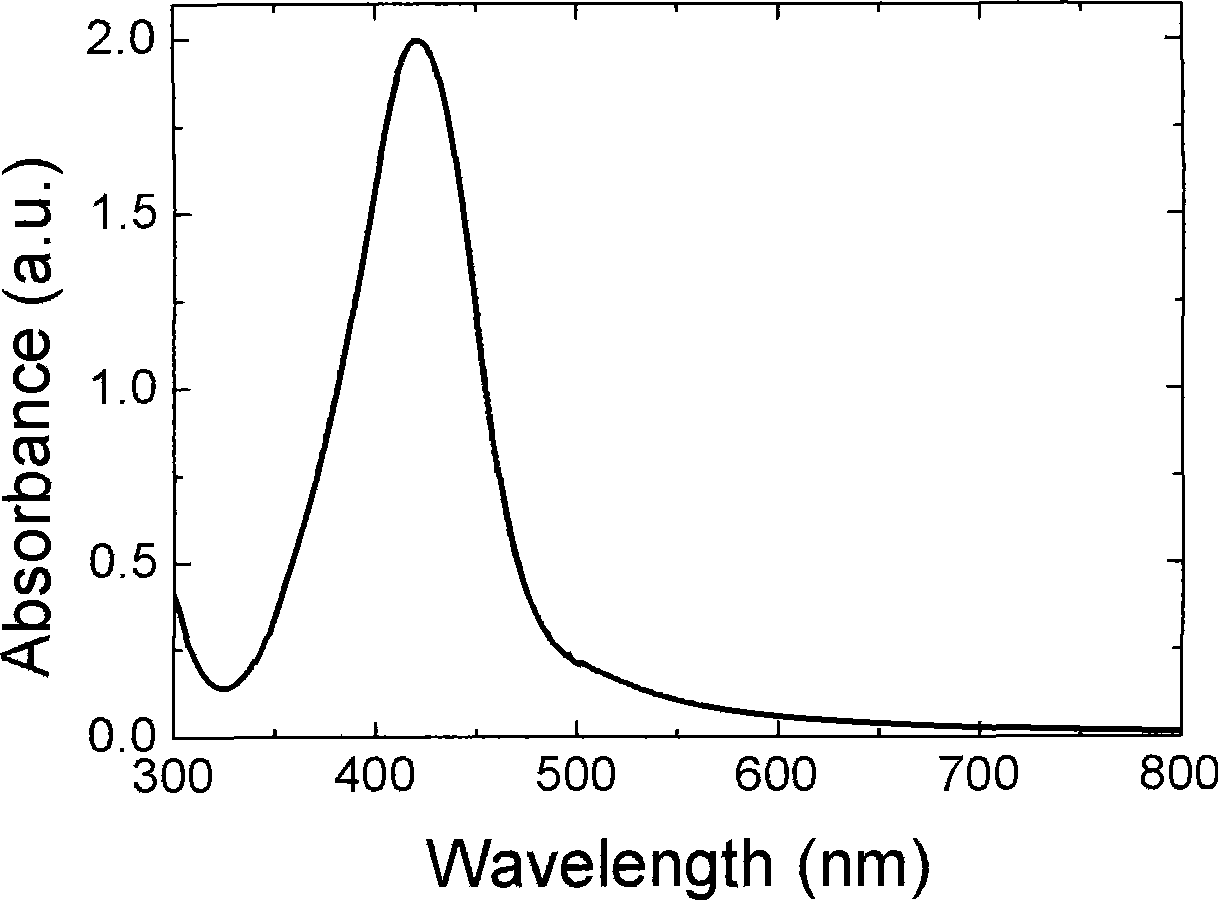

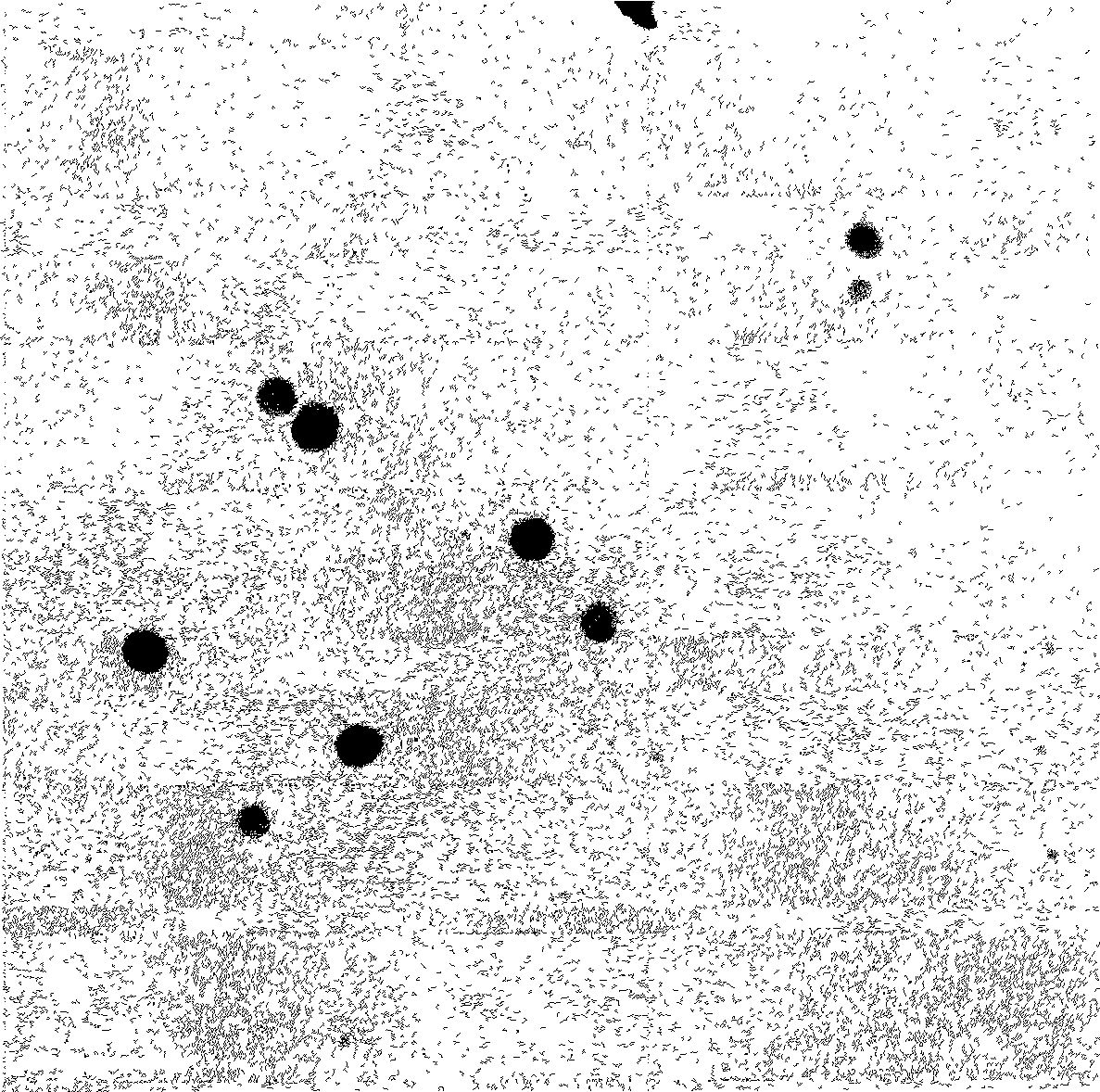

Method for preparing silver chloride sol and silver sol from AgCl powder

A silver chloride, silver sol technology, applied in silver halide and other directions, can solve the problems of troublesome process, many reagents, low AgCl powder processing ability, etc., and achieve the effect of simple operation procedure and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weighed 28.6 mg (0.2 mmol) of AgCl powder, then added 1 ml of DMF, then added concentrated hydrochloric acid dropwise and oscillated until the AgCl powder was completely dissolved, thereby obtaining the corresponding Ag-Cl complex solution. The solution was further added into DMF to dilute to 50 times, after adding 0.2mmol PVP, under constant stirring, drip into solvent (water, methanol, or ethanol), until a milky white transparent or translucent solution was formed, to obtain corresponding AgCl sol.

Embodiment 2

[0020] Weighed 28.6 mg (0.2 mmol) of AgCl powder, then added 1 ml of DMF, then added concentrated hydrochloric acid dropwise and oscillated until the AgCl powder was completely dissolved, thereby obtaining the corresponding Ag-Cl complex solution. The solution was further added to DMF to dilute to 100 times, and then 0.2 mmol of PVP was added and stirred until completely dissolved. Place the container of the solution in a small desiccator, and keep the solution in it under constant stirring; at the same time, place another open container, add a small amount of solvent (water, methanol, or ethanol), and then put The desiccator lid was closed so that the Ag-Cl complex solution was in the vapor from the solvent (water, methanol, or ethanol). When the diluted Ag-Cl complex solution turns milky white transparent or translucent, the corresponding AgCl sol is obtained.

Embodiment 3

[0022] Weighed 14.3 mg (0.1 mmol) of AgCl powder, then added 1 ml of DMF, then added concentrated hydrochloric acid dropwise and oscillated until the AgCl powder was completely dissolved, thereby obtaining the corresponding Ag-Cl complex solution. This solution is further added into DMF and diluted to 100 times, after adding 0.05mmol PVP, under constant stirring, drop a mixed solvent (a mixed solvent of two solvents in water, ethanol or methanol, or a mixed solvent of three kinds of solvents) solvent), until a milky white transparent or translucent solution is formed, that is, the corresponding AgCl sol is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com