Heat treatment method for steel cylinder for liquefied petroleum gas

A technology of liquefied petroleum gas and heat treatment method, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., and can solve the problems of incomplete welding stress relief, unreasonable design of heat treatment process temperature, and attenuation of mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

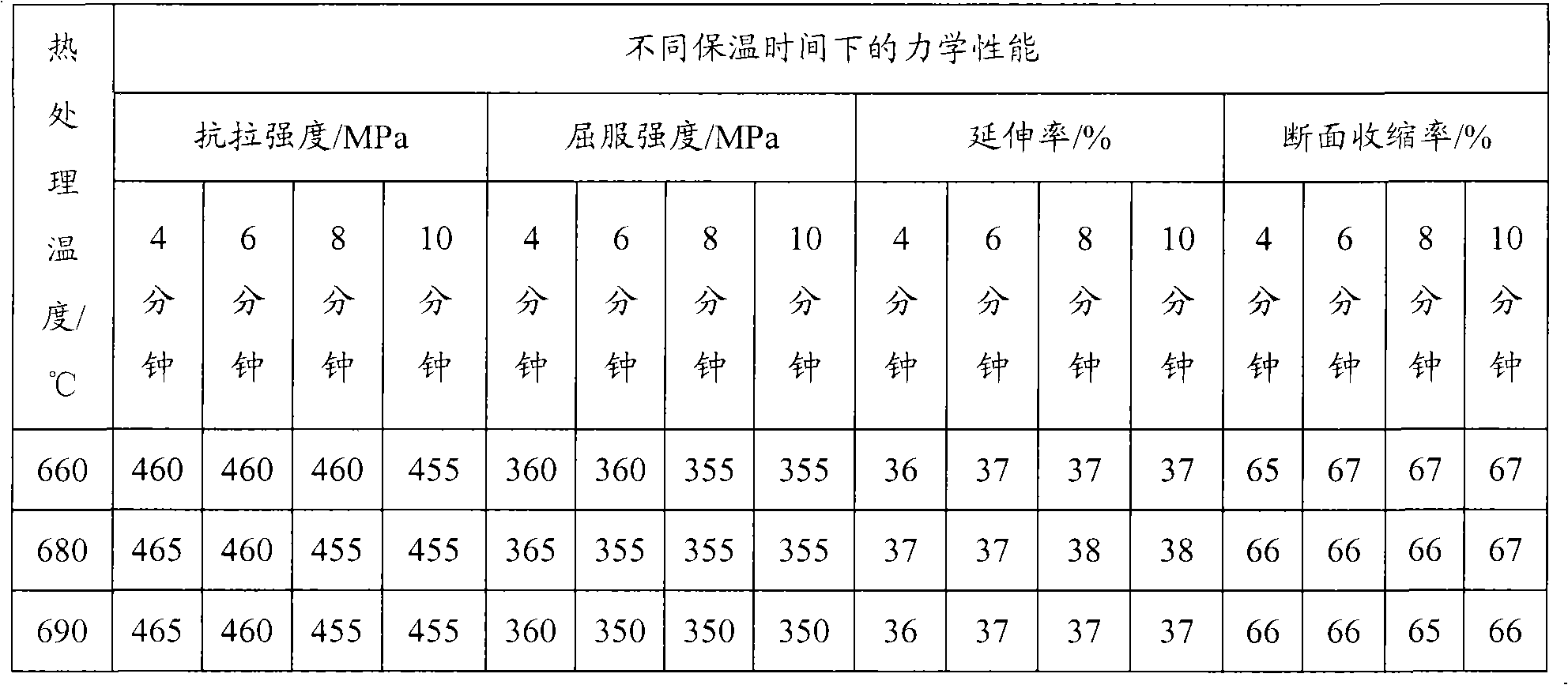

Embodiment 1

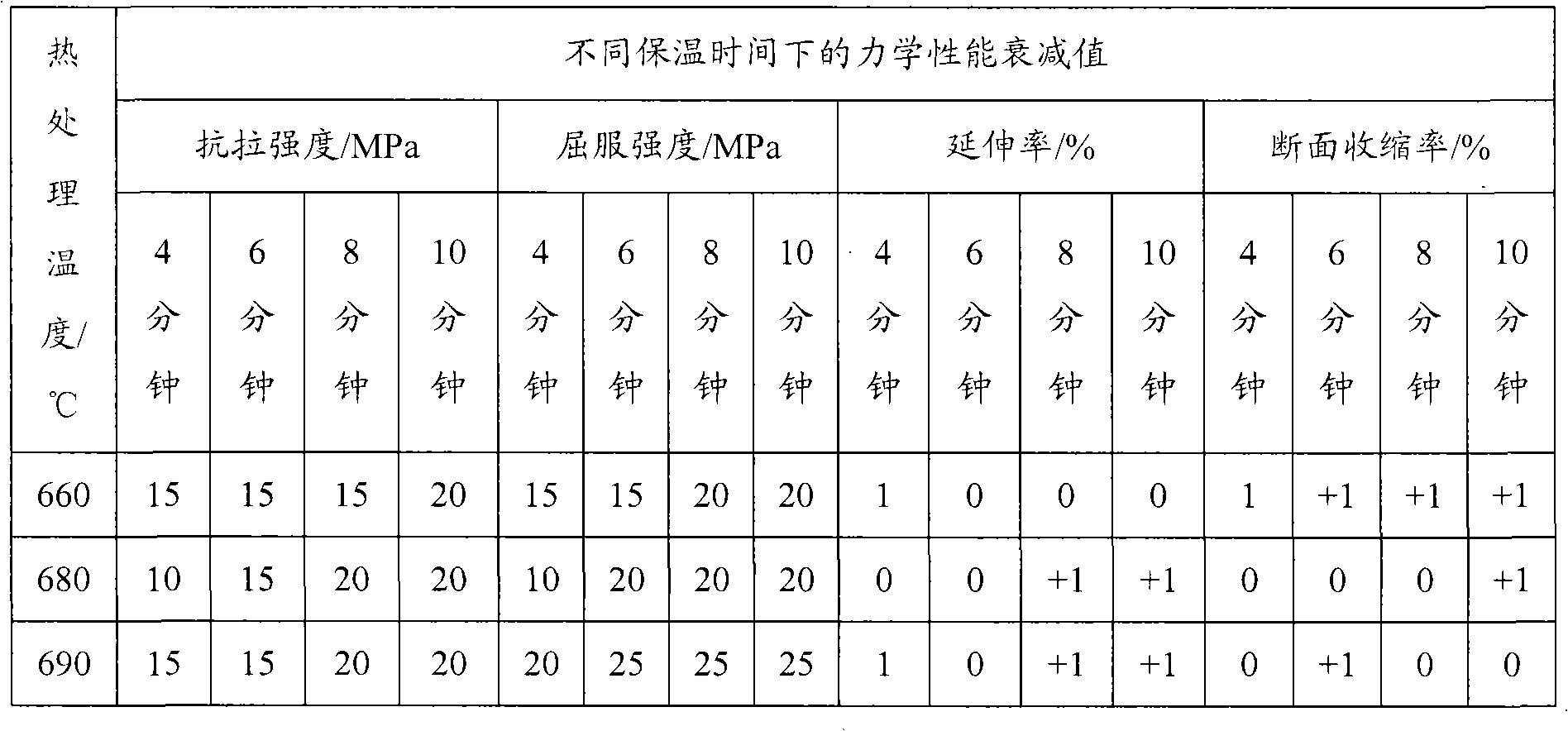

[0021] Use HP295 hot-rolled steel plate to make steel cylinders and weld them. Heat the heat treatment furnace to 660°C, send the liquefied petroleum gas cylinders into the heat treatment furnace, make the temperature of the liquefied petroleum gas cylinders gradually reach 660°C, and keep them in the furnace for 6 minutes. Finally, take the liquefied petroleum gas cylinder out of the heat treatment furnace, and let it cool naturally in the air to eliminate all stress. The mechanical properties at a temperature of 660°C are: the tensile strength Rm is 460MPa, the yield strength ReL is 360MPa, the elongation A is 37%, and the reduction of area Z is 67%. The attenuation of mechanical properties at this temperature is low, and the attenuation range of tensile strength and yield strength is only 15MPa, while the elongation and area reduction rate remain unchanged or increase, ensuring the service performance of the steel cylinder.

Embodiment 2

[0023] Use HP295 hot-rolled steel plate to make steel cylinders and weld them, heat the heat treatment furnace to 680°C, send the liquefied petroleum gas cylinders into the heat treatment furnace, make the temperature of the liquefied petroleum gas cylinders gradually reach 680°C, keep them in the furnace for 4 minutes, Finally, take the liquefied petroleum gas cylinder out of the heat treatment furnace, and let it cool naturally in the air to eliminate all stress. The mechanical properties at a temperature of 680°C are: the tensile strength Rm is 465MPa, the yield strength ReL is 365MPa, the elongation A is 37%, and the reduction of area Z is 66%. The attenuation of mechanical properties at this temperature is low, and the attenuation range of tensile strength and yield strength is only 10MPa, while the elongation and area reduction remain unchanged, which ensures the service performance of the steel cylinder.

Embodiment 3

[0025] Use HP295 hot-rolled steel plates to make steel cylinders and weld them. Heat the heat treatment furnace to 690°C, send the liquefied petroleum gas cylinders into the heat treatment furnace, make the temperature of the liquefied petroleum gas cylinders gradually reach 690°C, and keep them in the furnace for 8 minutes. Finally, take the liquefied petroleum gas cylinder out of the heat treatment furnace, and let it cool naturally in the air to eliminate all stress. The mechanical properties at a temperature of 690°C are: the tensile strength Rm is 455MPa, the yield strength ReL is 350MPa, the elongation A is 37%, and the reduction of area Z is 65%. The attenuation of mechanical properties at this temperature is low, the attenuation range of tensile strength and yield strength is only 20MPa and 25MPa, while the elongation remains unchanged, and the attenuation of the reduction of area is very low, which can fully guarantee the service performance of the steel cylinder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com