Environment-friendly copper base-steel bi-metal shaft bushing material and manufacturing method thereof

A technology of bimetallic shafts and manufacturing methods, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of human body poisoning, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

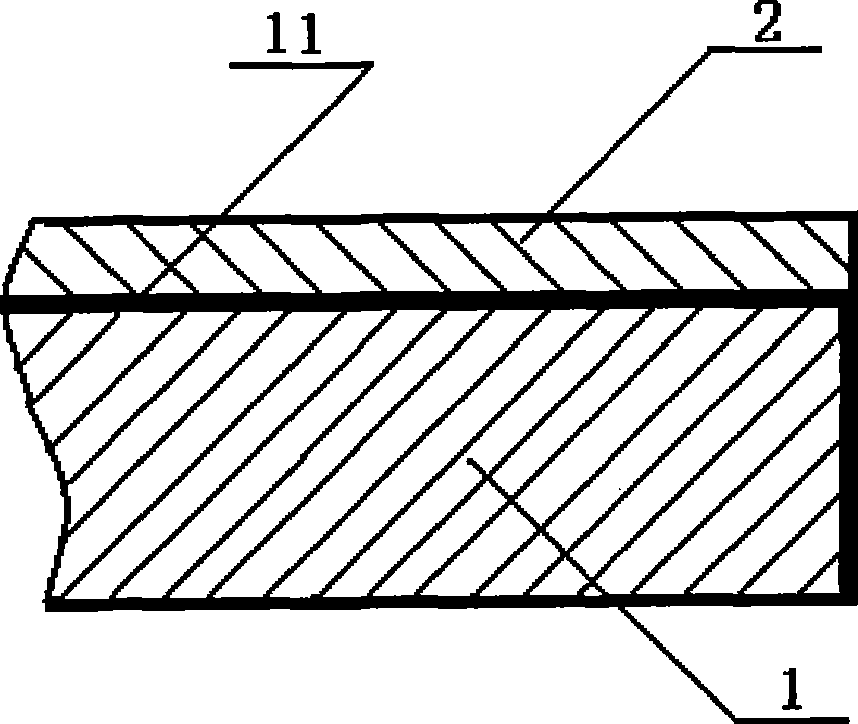

[0008] Such as figure 1 Shown is the schematic diagram of the present invention, which is composed of a steel plate 1 and a copper-based alloy wear-resistant layer 2; wherein, the formula composition of the copper-based alloy wear-resistant layer 2 is by weight percentage: bismuth 1% to 15%, tin 0.5% % to 10%, zinc 0.3% to 15%, and the balance copper.

[0009] A layer of copper 11 is plated on the steel plate 1 in the present invention.

[0010] In specific implementation, copper plating 11 or no copper plating 11 can be performed as required.

[0011] In the present invention, the copper-based alloy wear-resistant layer 2 is sintered or cast on the steel plate 1 .

[0012] The sintering in the present invention refers to the composition of the copper-based alloy wear-resistant layer 2, pre-prepared by 1% to 15% of bismuth, 0.5% to 10% of tin, 0.3% to 15% of zinc, and the balance is copper. The mixture is melted and atomized into copper-based alloy powder, and then the copp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap