Multifunctional free clutch

A multi-functional, clutch technology, applied in the direction of clutches, mechanical drive clutches, belts/chains/gears, etc., can solve problems such as insufficient torque, waste of resources, poor performance, etc., reduce equipment power configuration, improve production efficiency, and have a wide range of uses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

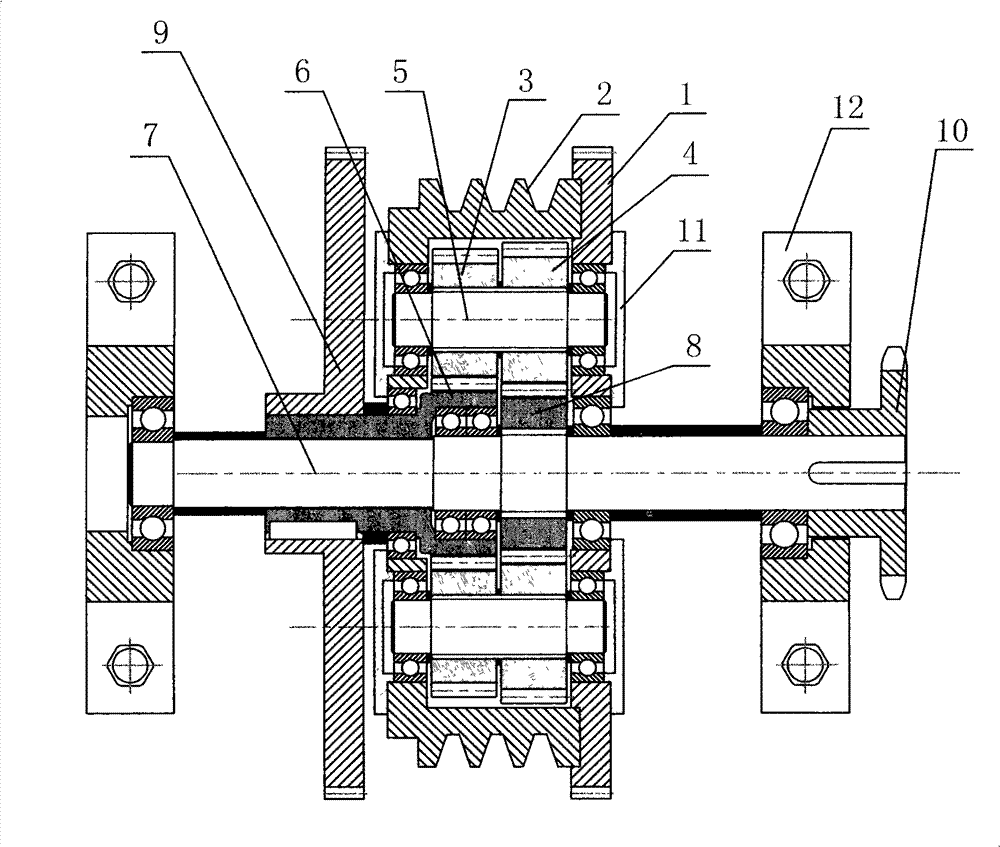

[0037] as attached figure 1 Shown, the multifunctional free clutch of the present invention, its structure comprises planetary gear train frame, planetary gear train, sun gear train;

[0038] The planetary gear train frame includes a frame gear 1 and a frame pulley 2 that are fixedly connected coaxially. Two sets of planetary gear trains are arranged in the cavity formed by the frame gear 1 and the frame pulley 2. The two sets of planetary gear trains are based on the frame gear 1 wheel The central axis is a symmetrical point, which is symmetrically arranged on the diameter of the frame gear 1 wheel disc.

[0039] The planetary gear train includes an input planetary gear 3, an output planetary gear 4 and a planetary gear shaft 5. The input planetary gear 3 and the output planetary gear 4 are splined to the planetary gear shaft 5, and one end of the planetary gear shaft 5 is connected to the frame gear 1 through a bearing. On the planet shaft shaft hole 4, the other end is con...

Embodiment 2

[0043] as attached Figure 13 As shown, the multi-functional free clutch is used as a clutch, and its function is equivalent to the function of two electromagnetic clutches, and its advantage is that there is no free change in speed during the neutral time.

[0044] Take the currently widely used rotary cutting machine as an example, as attached Figure 13 As shown, the working principle and application method are as follows: the main force 19 is passed into the hanging wheel frame shaft input sprocket 17 through the chain, the hanging wheel frame shaft is input into the sprocket 17, the constant connection thickness conversion hanging wheel frame 14, the thickness quick change control hanging wheel The wheel frame 15 is coaxially threaded on the wheel frame shaft 16, and there is a flat key connection between them, and the thickness of the wheel frame 14 is connected to the input gear 9 of the multifunctional free clutch 13, which can be kept connected without disconnection. ...

Embodiment 3

[0049] The multifunctional free clutch also has the function of a speed reducer and can be directly used as a speed reducer.

[0050] The multifunctional free clutch is directly used as a reducer, and it needs to be attached figure 1 The following changes are made on the basis of the shown structure: (1) the tooth profile of the frame gear 1 is canceled, and the rest of the structure remains unchanged, and the name is changed to the planetary gear frame 1; (2) the input gear 9 and the output sprocket 10 are cut; ( 3) Redesign the output shaft bearing seat 12 on one side, add an inner hole for fixing the input sun gear 6, and draw a keyway; the application method is as follows:

[0051] Except for the above three changes, the structure of the other free clutches remains unchanged. Only the outer circle of the sleeve of the input sun gear 6 protruding from the planetary gear frame 1 is fixed on the inner hole of the output shaft bearing seat 12 through a flat key to form a frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com