Early warning method for failure of water-cooling wall of power boiler

A technology for power station boilers and water-cooled walls, applied in electrical digital data processing, special data processing applications, control systems, etc., can solve the problems of deterioration of heat transfer, dependence on a large number of empirical parameters, and large error values, and achieve equipment optimization. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

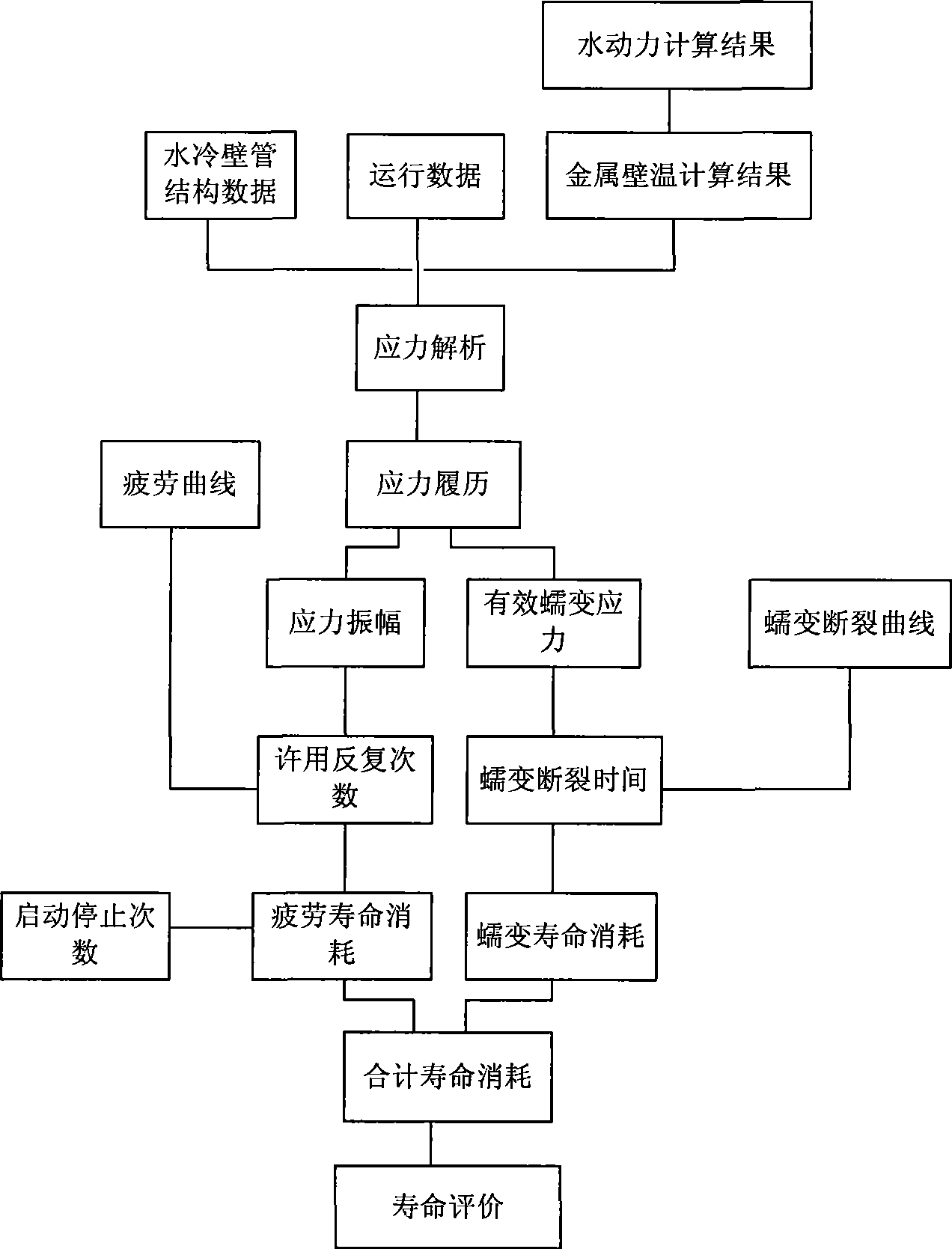

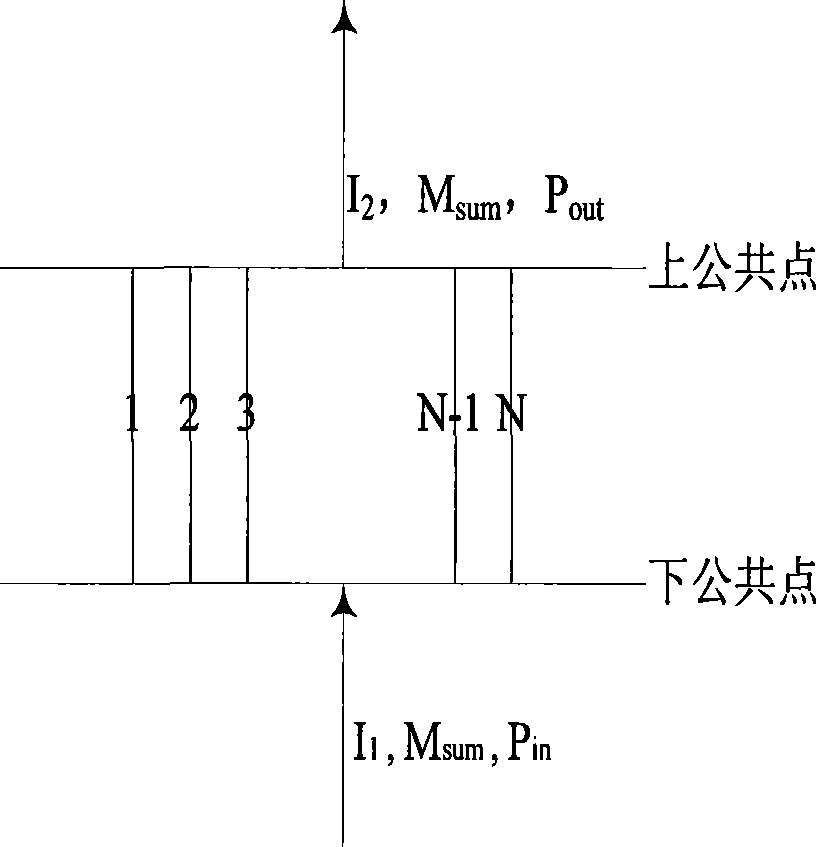

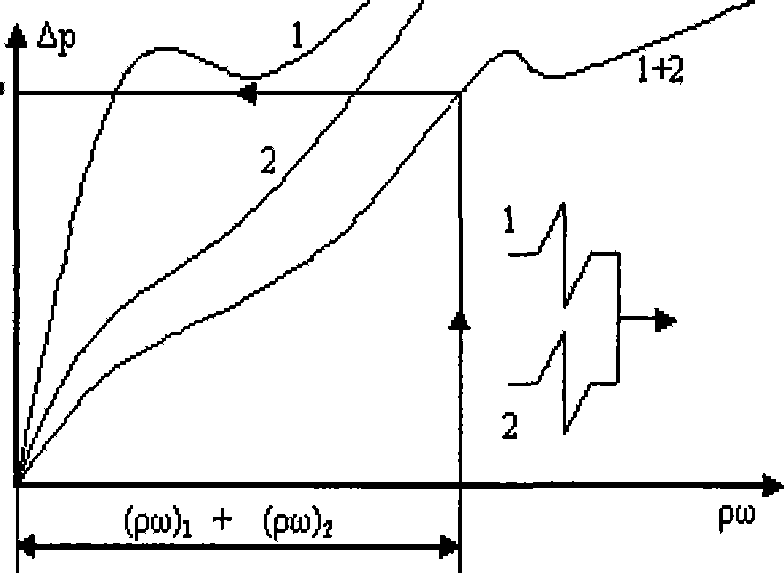

[0038] Reference figure 1 As shown, first, divide the water wall circuit according to the boiler structure and operation data of the power station, combine the total flow of the water wall during operation and the inlet pressure data, and perform the hydrodynamic calculation to obtain the flow and pressure data of each circuit;

[0039] Secondly, on the basis of the structure data and the flow and pressure data of each circuit, the numerical method is used to calculate the metal wall temperature to obtain the temperature field of the entire fin tube;

[0040] Once again, on the basis of obtaining the pressure, flow rate, and wall temperature of the entire fin tube of the water wall, according to the formula σ p =K P PD / 2S S Tangential film stress σ p , Where P is the working pressure, MPa; D is the average value of the outer and inner diameters of the pipe, mm; S s Is the actual wall thickness of the pipe, mm; K p Is the comprehensive weakening factor and stress concentration fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com