Electrode material used for organic inorganic composite cell and manufacturing process

An inorganic composite and electrode material technology, applied in battery electrodes, circuits, photovoltaic power generation, etc., can solve problems such as expensive, unstable reactants, and complex preparation processes, and achieve the effect of improving charge separation and transmission capabilities and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

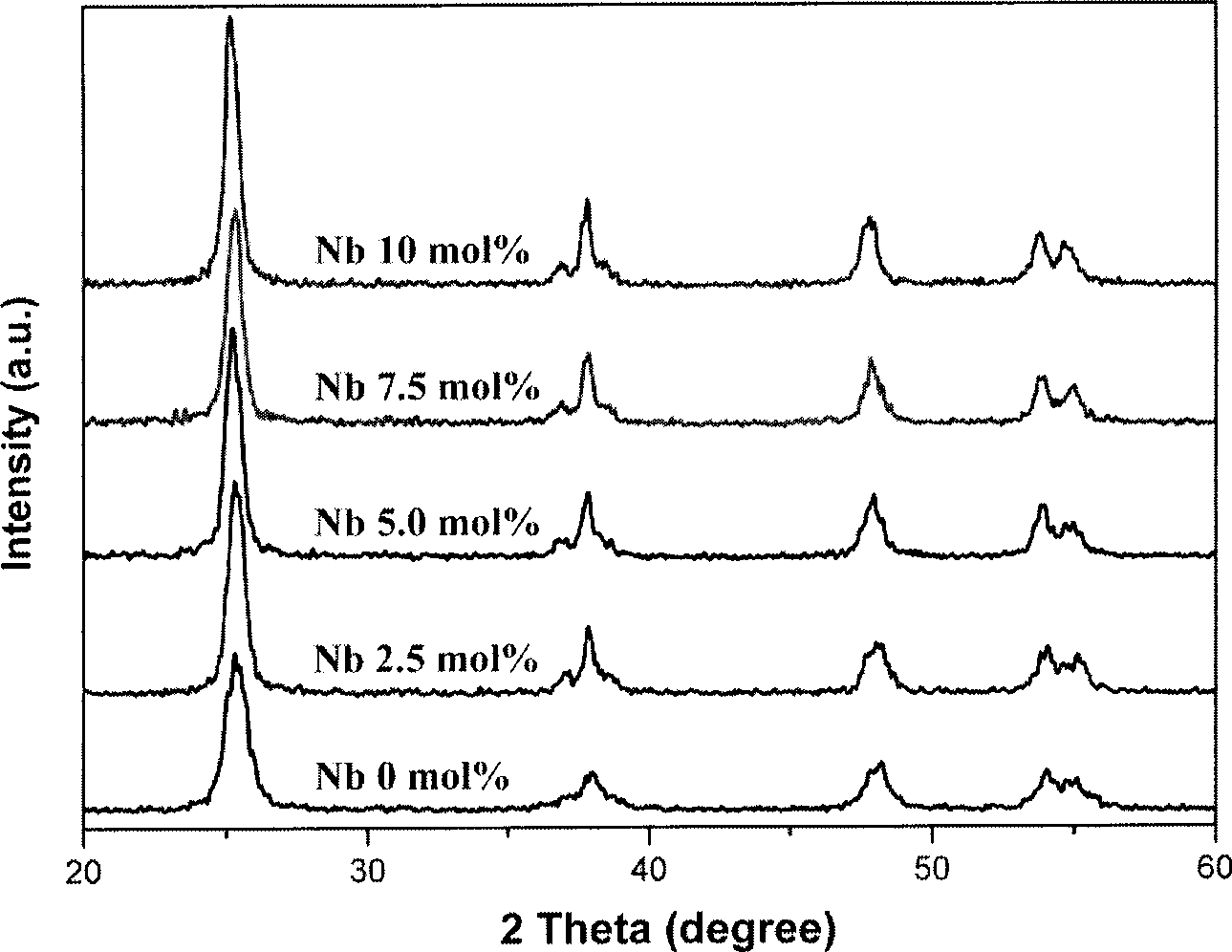

[0033] Add tetrabutyl titanate dropwise to 50ml of a mixed solvent of ammonia (25-28%) and hydrogen peroxide (30%) (NH 3 ·H 2 O:H 2 o 2 =1:5), fully stirred to obtain a transparent solution, then raised the temperature to 80°C to remove excess hydrogen peroxide and organic matter, and obtained a suspension after stirring for 2 hours. Move the suspension to a reaction kettle, keep it warm at 180°C for 20 hours, cool naturally to obtain the target precipitate, wash the precipitate with deionized water for 3 to 5 times, and dry to obtain the undoped titanium dioxide powder material. After characterization, the obtained powder is a pure-phase anatase structure, such as figure 1 As shown, the powder is nanoparticles with uniform particle size distribution, the average particle size is slightly less than 10nm, and its microscopic TEM photo is shown in figure 2 (a) shown.

[0034] Prepare the obtained powder with ethyl cellulose, polyethylene glycol and turpentine permeabilizat...

Embodiment 2

[0036] Add 1mmol metal elemental niobium to 50ml of ammonia (25-28%) and hydrogen peroxide (30%) mixed solvent (NH 3 ·H 2 O:H 2 o2 =1:5), after stirring in a cold water bath for a period of time, a uniform niobium precursor solution with a concentration of 0.02M was obtained. Add 39mmol tetrabutyl titanate dropwise to the niobium precursor solution to control the doping concentration of niobium to 2.5mol%, stir the transparent solution thoroughly, and then raise the temperature of the mixed solution to 80°C to remove excess hydrogen peroxide and organic matter , A suspension was obtained after stirring for 2 h. Move the suspension to a reaction kettle, keep it warm at 180°C for 20 hours, cool naturally to obtain the target precipitate, wash the precipitate with deionized water for 3 to 5 times, and dry to obtain titanium dioxide with a niobium doping amount of 2.5 mol%. Powder material. After characterization, the obtained powder is a pure-phase anatase structure, and the ...

Embodiment 3

[0039] Add 2mmol metal elemental niobium into 50ml of ammonia (25-28%) and hydrogen peroxide (30%) mixed solvent (NH 3 ·H 2 O:H 2 o 2 =1:5), after stirring in a cold water bath for a period of time, a uniform niobium precursor solution with a concentration of 0.04M was obtained. Add 38mmol tetrabutyl titanate dropwise to the niobium precursor solution to control the doping concentration of niobium to 5.0mol%, stir well to obtain a transparent solution, and then raise the temperature of the mixed solution to 80°C to remove excess hydrogen peroxide and Organic matter, after stirring for 2h, a suspension was obtained. Move the suspension to a reaction kettle, keep it warm at 180°C for 20 hours, cool naturally to obtain the target precipitate, wash the precipitate with deionized water for 3 to 5 times, and dry to obtain titanium dioxide with a niobium doping amount of 5.0 mol%. Powder material. After characterization, the obtained powder is a pure-phase anatase structure, suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com