Hydraulic brake

A technology of hydraulic brake and active friction plate, applied in the direction of hydraulic brake, etc., can solve the problem of not considering the fluidity of friction plate and bearing lubricating oil, the friction force of disc spring pre-pressure friction plate cannot be adjusted, and it is difficult to meet market demand, etc. problems, achieving favorable cooling, wide availability, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

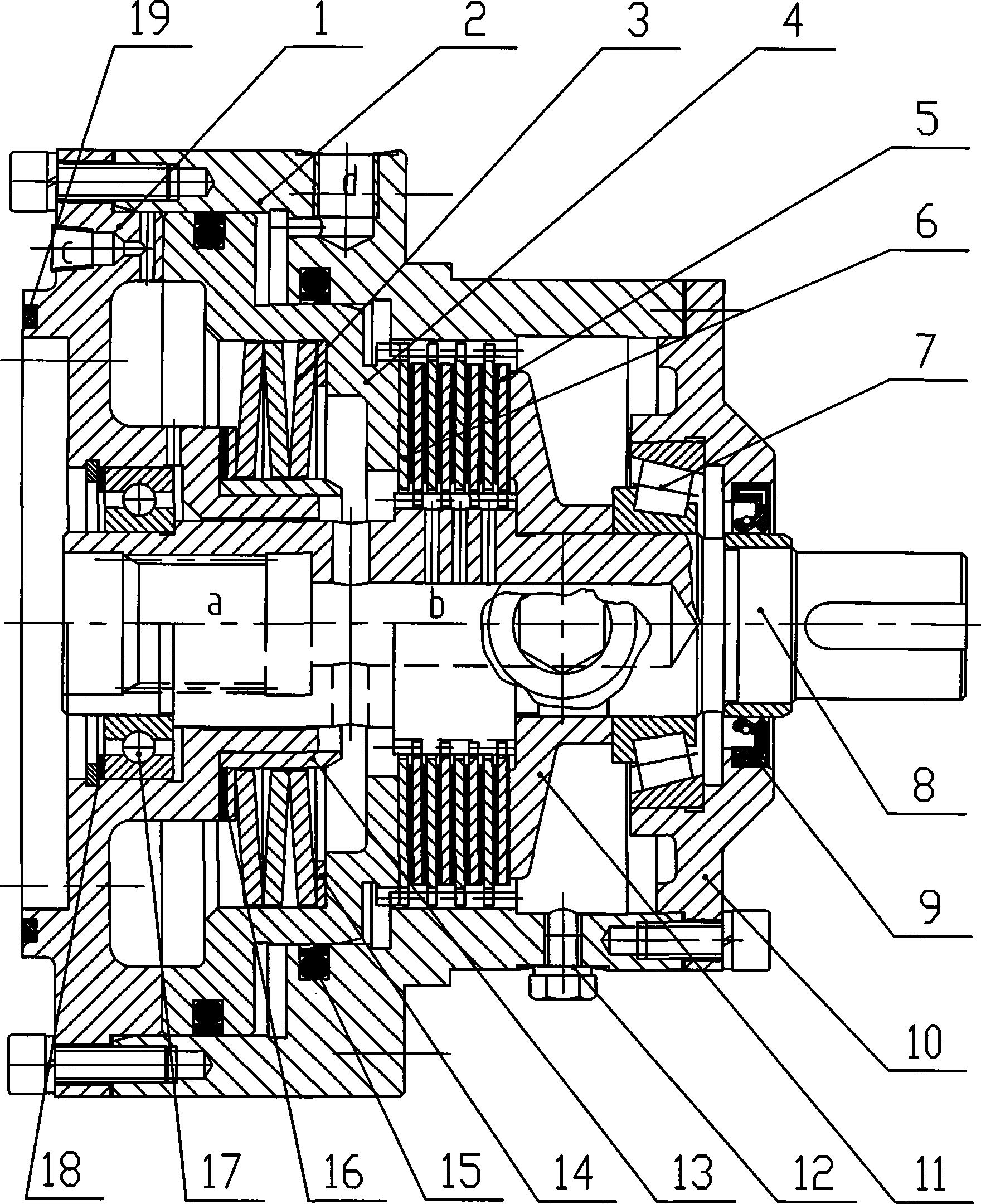

[0010] The hydraulic motor hydraulic brake of the present invention is mainly composed of a left end cover 1, a housing 2, a disc spring 3, an oil cylinder piston 4, an active friction plate 5, a driven friction plate 6, a friction plate baffle plate 11 and a right end cover 10. The main shaft 8 is provided with In the casing 2, there is a blind hole a on the shaft center of the matching end of the main shaft 8 and the hydraulic motor. The blind hole a is stepped and extends to the exit of the casing 2, which is a hollow transmission shaft. There is a blind hole a in the blind hole a. Fitting spline slots for hydraulic motors. The active friction plate 5 and the driven friction plate 6 are arranged between the main shaft 8 and the housing 2. The active friction plate 5 and the main shaft 8 are connected by involute splines, and rotate with the rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com