High-power LED lamp circuit with fan

A LED lamp, high-power technology, applied in the direction of lamp circuit layout, circuit, circuit layout, etc., can solve the problem that the channel current cannot be cut off, and achieve the effects of low power consumption, long service life and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] like Figure 7 As shown, the high-power LED lamp with a fan in this embodiment is a downlight applied in the ceiling, including an LED heat dissipation substrate 20, a metal heat dissipation member 30, a heat dissipation fan 40, a casing 50, a driving circuit board assembly 60, a reflector The cup 70 , the fixing seat 34 , the ring member 81 , the mounting elastic piece 82 , and the clip 83 . The LED heat dissipation substrate 20 is fixedly connected to a plurality of high-power LED chips 10 , that is, the LED load 3 . The LED heat dissipation substrate 20 is mounted on each A cofferdam 21 is fixedly connected to the periphery of the LED chip 10, and the cofferdam 21 is filled with phosphors and optical resins. and optical resin does not overflow, the effect is good, and the production efficiency is high. The LED heat dissipation substrate 20 and the LED chip 10 are provided with an LED protective cover 90 outside. The metal heat sink 30 is a fin type heat sink. The ho...

Embodiment 2

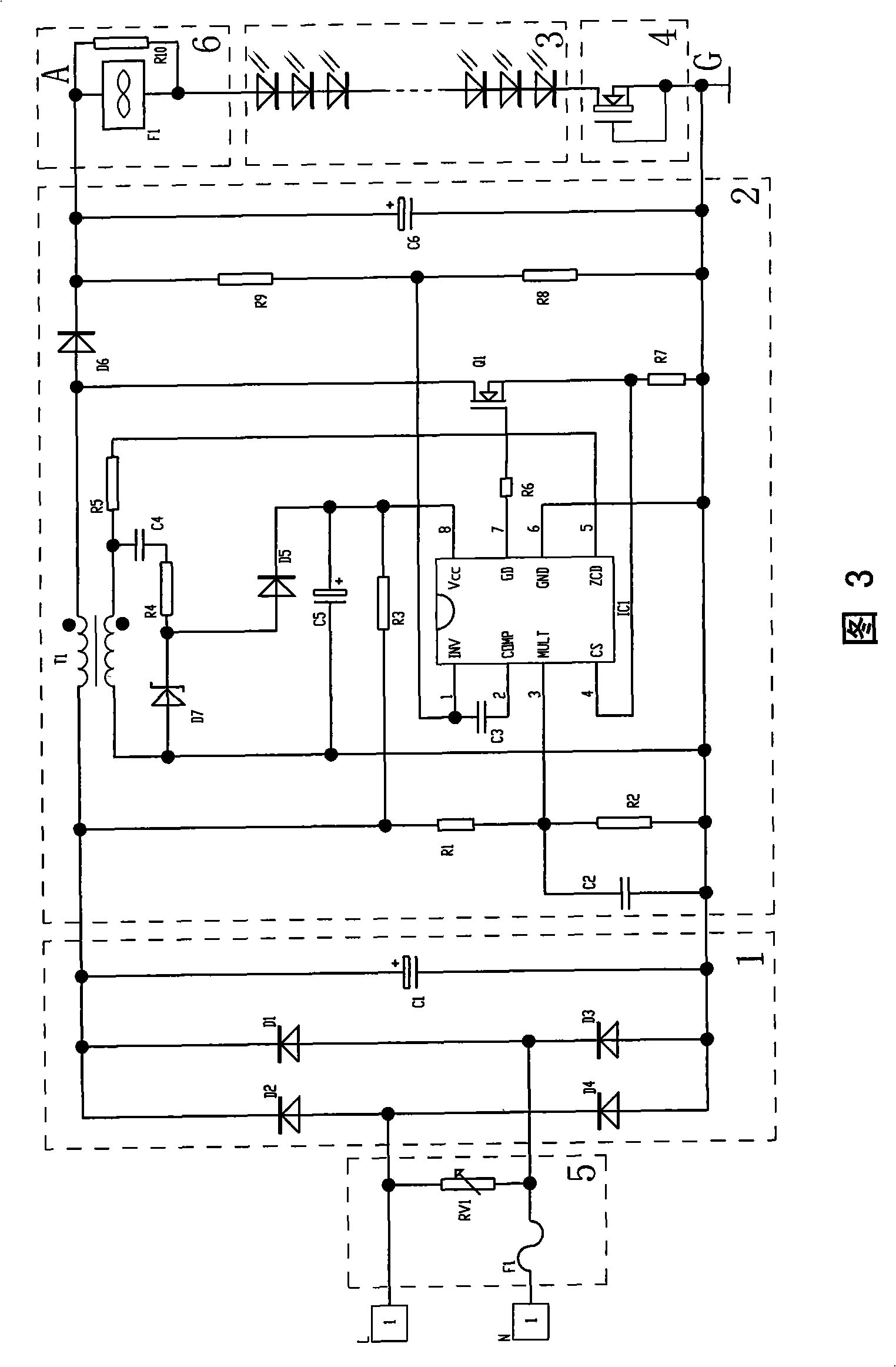

[0040] like Figure 4 As shown, the difference between this embodiment and the first embodiment is that the LED load 3 in this embodiment includes four groups of several LEDs connected in series, and each group of the LEDs is connected in series with one of the constant current source devices 4 , the four groups connected in series are connected in parallel with the fan circuit 6 as a whole, so there are four constant current source devices 4 in this embodiment. In this embodiment, the calculation method of the number of the LEDs connected in series in each group is the same as that in the first embodiment.

[0041] The remaining features of this embodiment are the same as those of the first embodiment.

Embodiment 3

[0043] like Figure 5 As shown, the difference between this embodiment and the first embodiment is that the LED load 3 in this embodiment includes four groups of several LEDs connected in series, and each group of the LEDs is connected in parallel with the fan circuit 6 as a whole. The constant current source device 4 is connected in series, that is, there is only one constant current source device 4 in this embodiment.

[0044] The remaining features of this embodiment are the same as those of the first embodiment.

[0045] Of course, as a simplified form, in the above implementation, the voltage regulator circuit 2 can be omitted, and the DC power can be provided only through the rectification filter circuit 1, which can also achieve the preliminary effect of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com