Power diode with trench field ring structure

A technology for power semiconductors and semiconductors, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve the problems of heavy metal pollution in the diffusion area and long diffusion time of dopants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

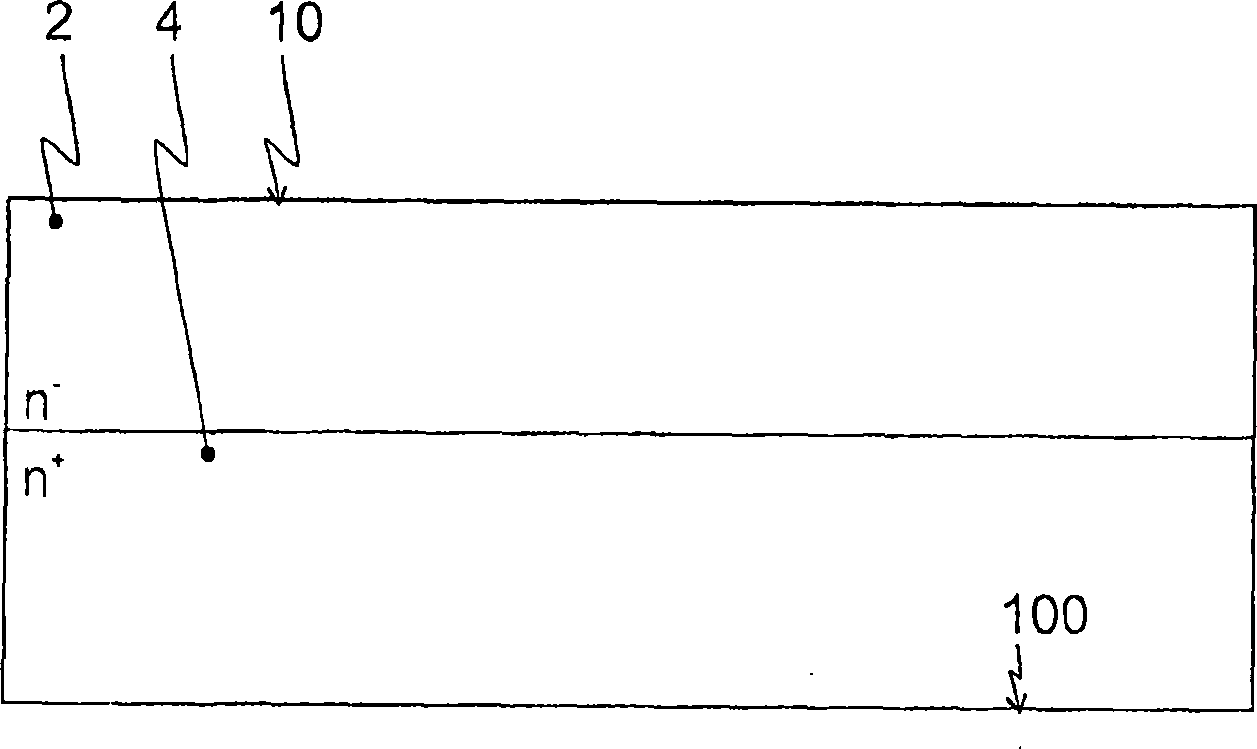

[0023] figure 1 Using the example of a power diode with a reverse voltage of 1200 V, parts of the base body 2 , 4 of the power semiconductor component according to the invention are shown not to scale. This example also applies in principle to the subsequent figures. In this case, the semiconductor body has two different concentrations of n-doping. Adjacent to the first surface 10 of the base body is a weakly doped region 2 , and adjoining the second surface 100 is a heavily doped region 4 . The boundaries of the two dopants run parallel to the surfaces 10 , 100 in the interior of the matrix.

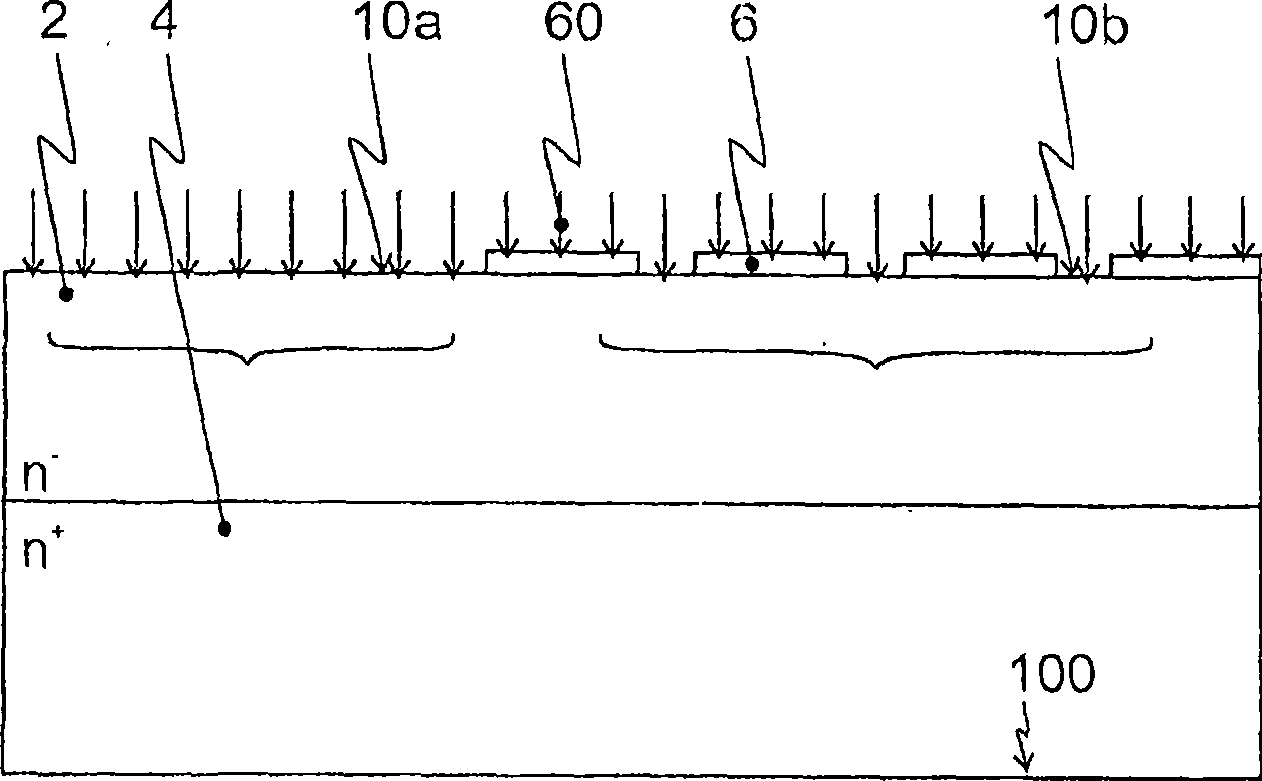

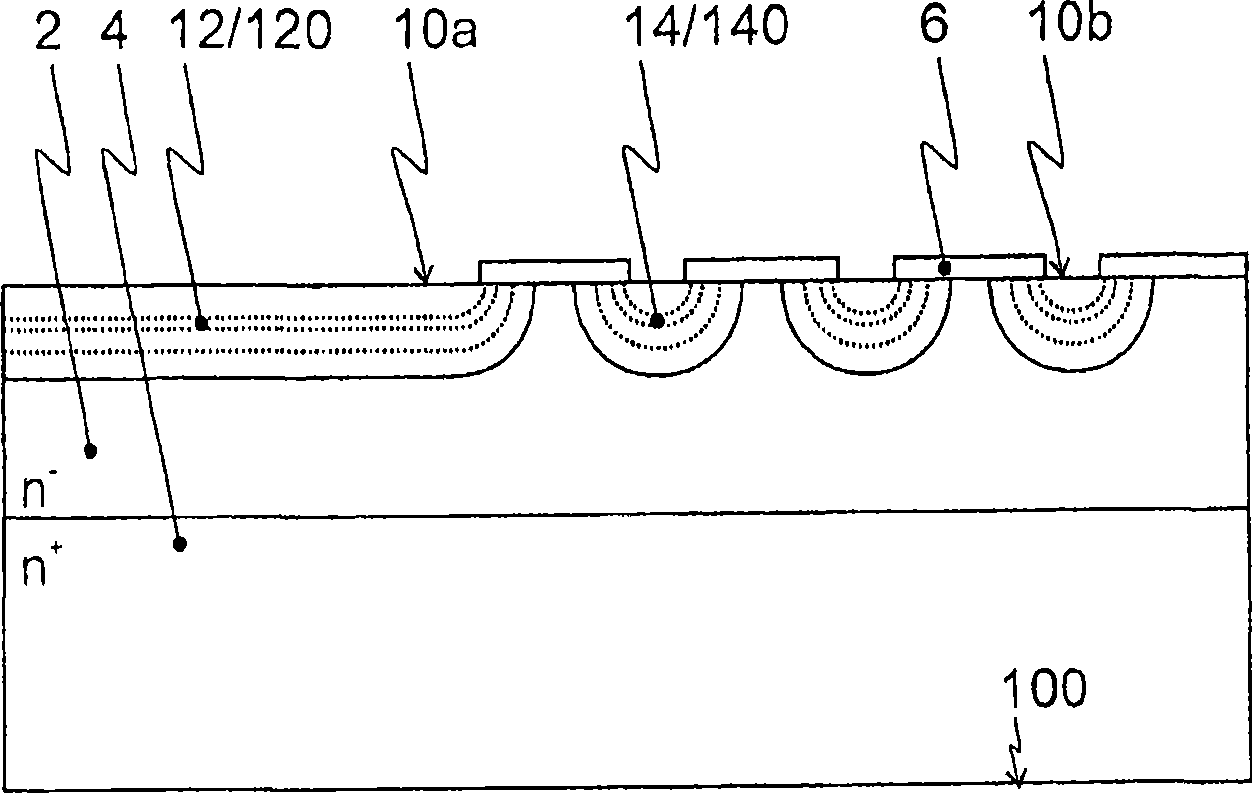

[0024] figure 2 Partial steps of a first method for forming a second doped doping profile both for the contact region and for the field ring structure are shown. According to the prior art, the different regions are here masked 6 in order to provide selective doping. The contact region is formed in the region of the first partial surface 10 a and the field ring of the field ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com