Mountain mulching film peanut seeder

A technology for mulching peanuts and planters, which is applied to parts of planters, machinery for interval-type quantitative seeding, planting methods, etc. The effect of moisture retention is obvious, the work intensity is small, and the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

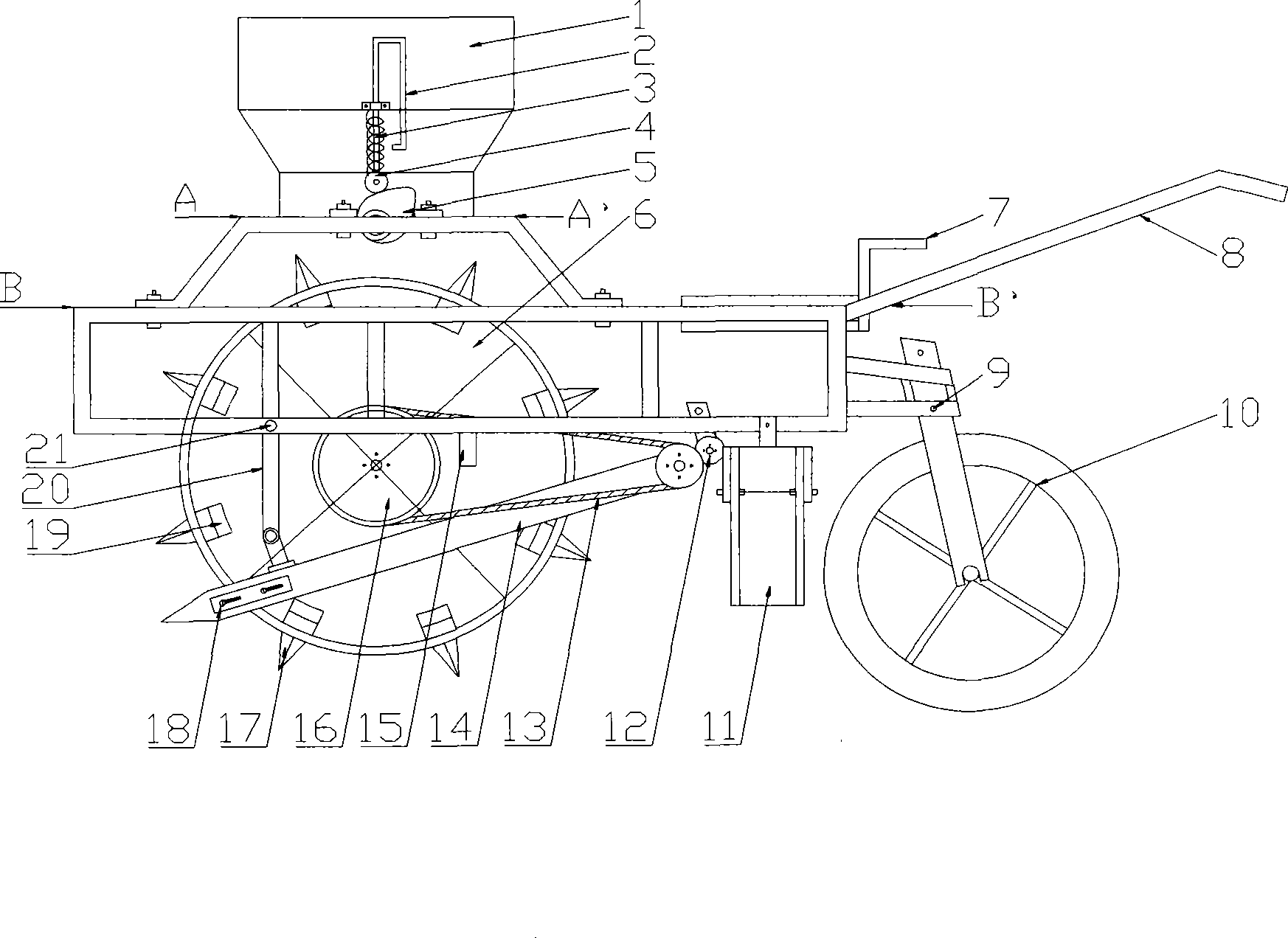

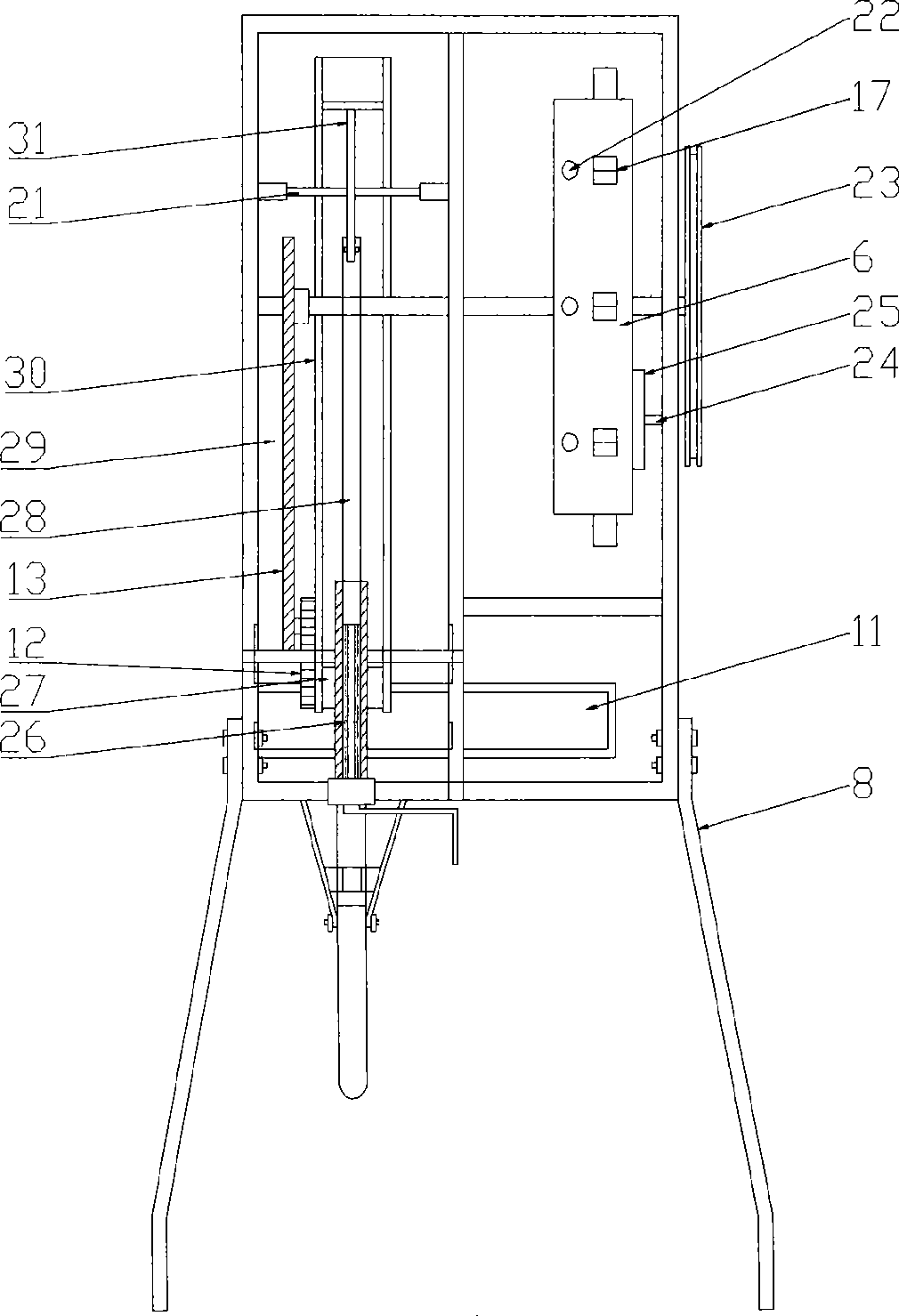

[0019] Mountain peanut planter with film mulching for mountain planting can be driven manually or driven by micro-mechanical power.

[0020] Such as figure 1 As shown, the mountain film mulching peanut planter is equipped with a seed box 1 on the upper part of the frame, and a seed box stirring rod 2 is installed in the box, which is equipped with a stirring rod return spring 3 and a stirring rod wheel 4 from top to bottom. The rod wheel 4 is pressed against the stirring rod wheel lifting block 5 fixed on the lower frame. The stirring rod wheel lifting block 5 is a convex wheel that rotates under the rotation of the coaxial upper pulley 36 to push the stirring rod wheel 4 to rotate At the same time, it moves up and down to drive the seed box stirring rod 2 to move up and down, agitating the seeds while sowing, to prevent jamming and cavitation.

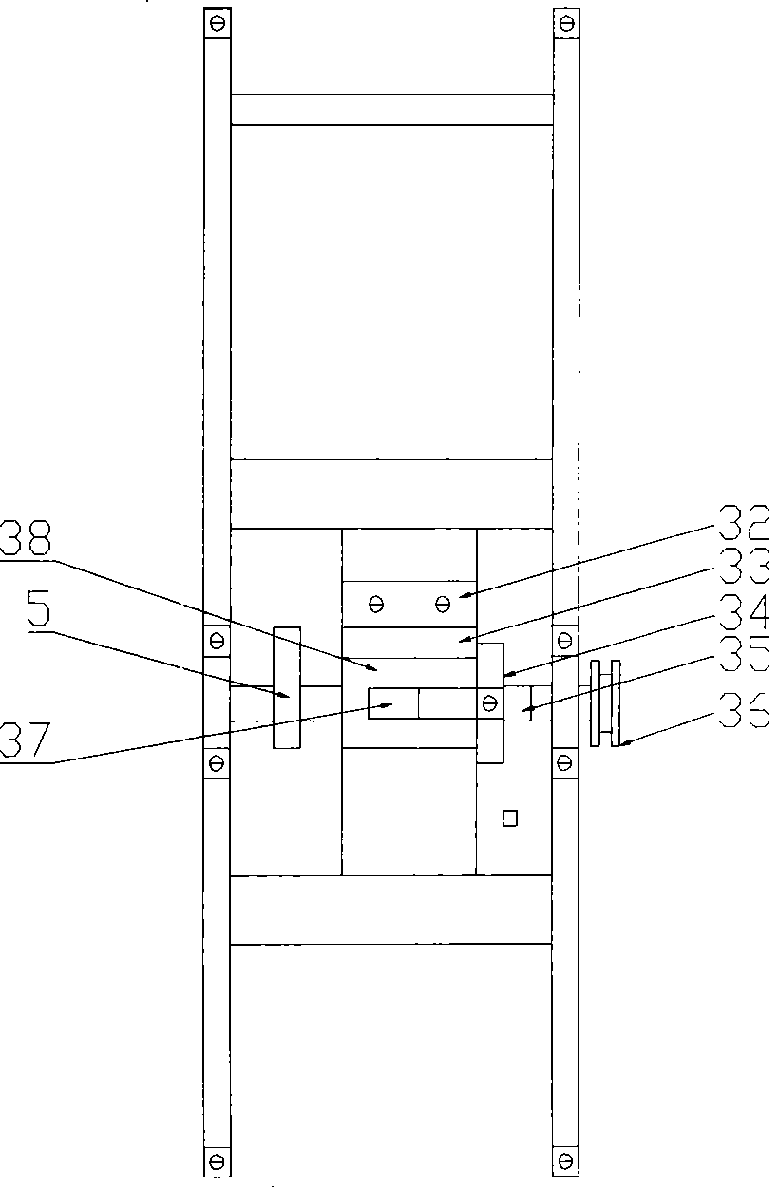

[0021] Such as Figure 4 As shown, 1 seed from the seed box enters the lower metering wheel 38, the right outer side of the shaft is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com