Automatic device for quantitatively distributing microfluid and using method

A quantitative distribution and microfluidic technology, applied in chemical instruments and methods, analytical materials, laboratory containers, etc., can solve the problems of difficulty in precise control of droplet size and low quantitative accuracy, and achieve simple processing and simple device structure. , the effect of improving quantitative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1. Microfluidic automatic quantitative distribution device

[0021] 1.1 Structure of the device

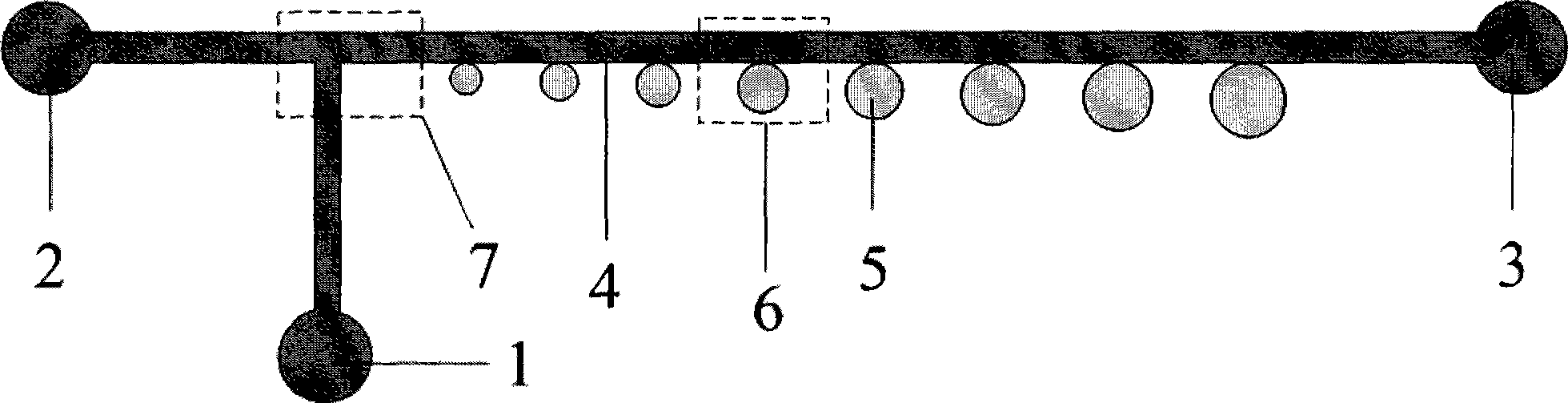

[0022] A structure provided by the present invention for implementing the above-mentioned microfluid automatic quantitative distribution device is as follows: figure 1 As shown, by comprising a sample liquid inlet 1, an immiscible fluid inlet 2 with the sample liquid, a fluid outlet 3, a microchannel 4 and a group of microcavity 5 located on the side of the microchannel and communicated with the microchannel A flow control chip is formed; wherein, the depth of the microcavity is greater than the depth of the microchannel.

[0023] The cross-section of the microchannel is rectangular or fan-shaped, the maximum width of the cross-section is 20-1000 microns, and the maximum height of the cross-section is 2-500 microns; wherein the width of the cross-section of the micro-channel is greater than its height. The shape of the microcavity is one of cylindrical, hemispheri...

Embodiment 2

[0030] Embodiment 2. The usage method of microfluidic automatic quantitative dispensing device

[0031] The microfluidic device made in Example 1 can use the following methods for quantitative distribution of microfluidic samples:

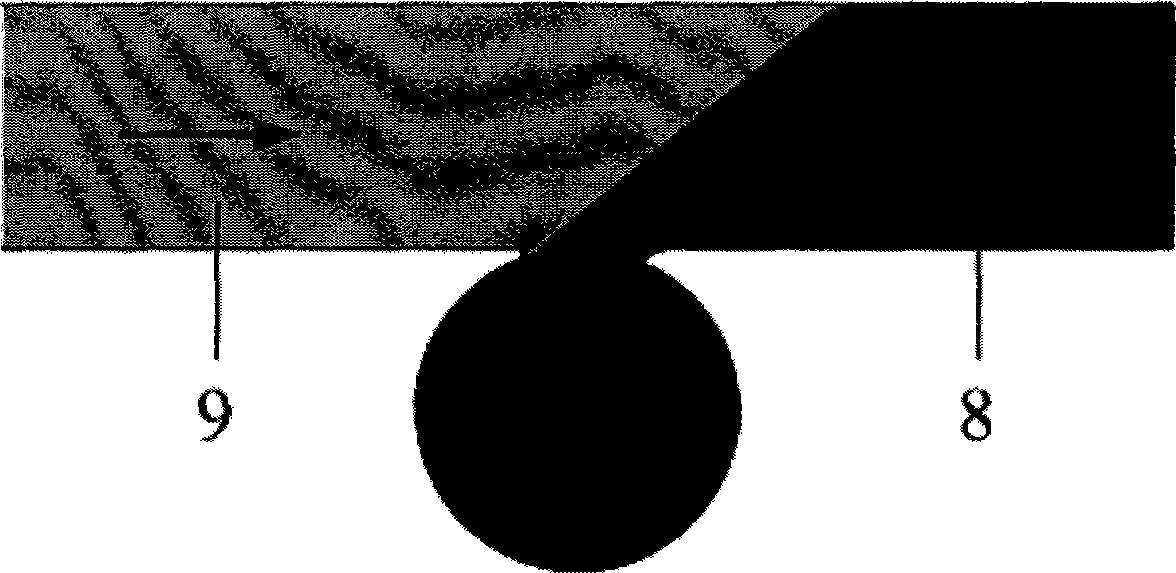

[0032] First, the aqueous phase sample liquid 8 to be quantitatively distributed is filled into the microchannel network 4 through the sample liquid inlet 1, and the sample liquid will enter the microchannel network 4 and the microcavity 5 connected thereto. After the sample liquid fills all the microcavities, the sample The liquid inlet 1 stops sampling, and the fluid 9 that is immiscible with the aqueous phase sample liquid is filled from the fluid inlet 2 at a certain flow rate, and the excess sample liquid 10 in the microchannel is removed by the shearing action of the fluid 9, wherein the fluid 9 The flow rate of the flow rate should not be too high, and it should be ensured that its shearing effect on the sample droplet in the microcavity is ...

Embodiment 3

[0033] Embodiment 3. The usage method of microfluidic automatic quantitative dispensing device

[0034] The microfluidic device made in Example 1 can also use the following methods for quantitative distribution of microfluidic samples:

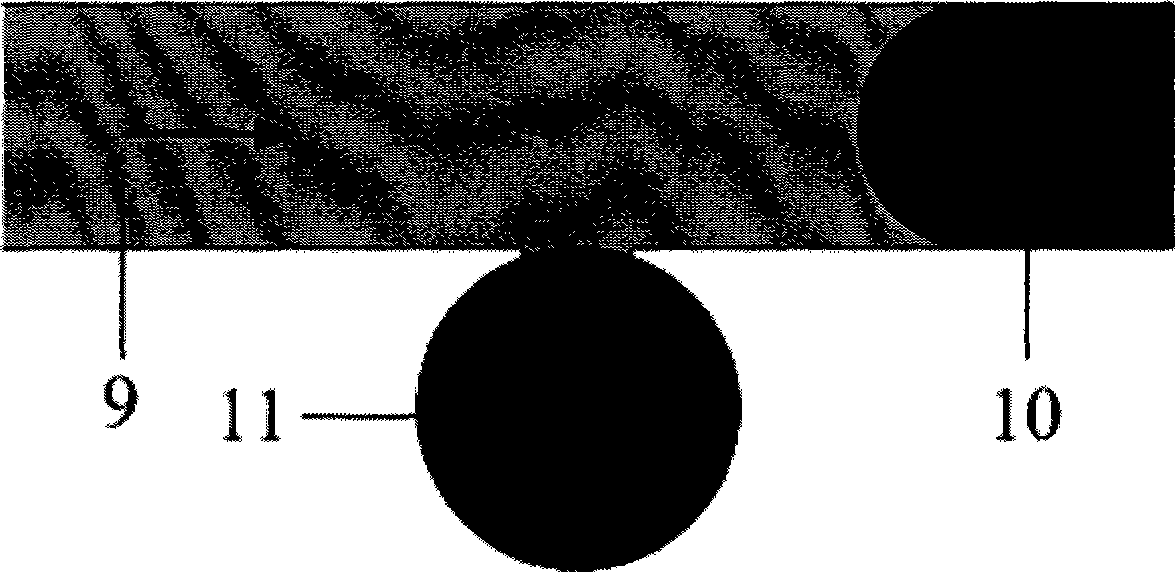

[0035] The aqueous phase sample liquid 8 to be quantitatively distributed and the fluid 9 immiscible with it are filled into the microchannel network 4 through the sample liquid inlet 1 and the fluid inlet 2 at the same time, and the sample liquid 8 at the intersection of the microchannel 7 will be due to the fluid 9 The shearing effect is dispersed into droplets, and when the droplets flow through the microcavity, the surface tension will cause the droplets to enter the microcavity until the microcavity is full, and the excess sample liquid 10 suspended in the microchannel will be under the shear of the fluid 9 It is cut off under the action of cutting, so that only the microcavity is filled with the sample liquid 11, so that the quantitative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com