Constant current source control circuit

A control circuit and constant current source technology, applied in energy-saving control technology, lamp circuit layout, light source, etc., can solve the problems of lower reliability, difficult implementation, difficult control, etc., and achieve the effect of improving efficiency, reducing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

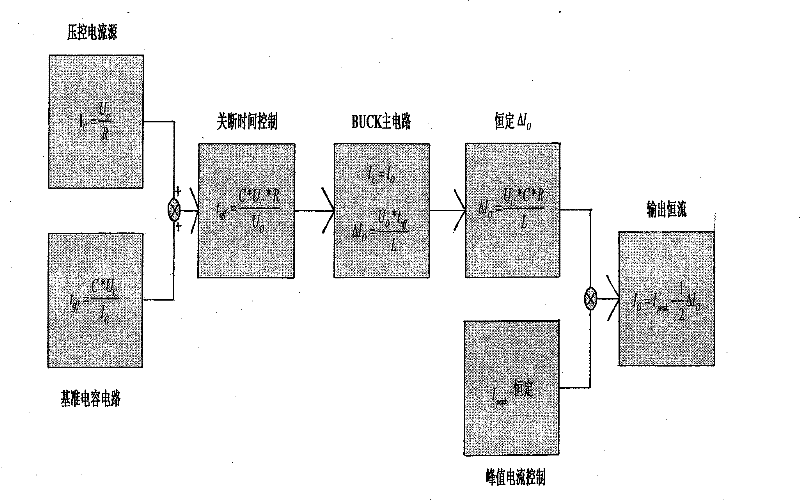

[0027] Refer to attached Figure 4 (a)-4(d), curve 4(a) is the waveform of the gate voltage of the switching tube, curve 4(b) is the waveform of the inductor current under CCM, curve 4(c) is the waveform of the reference capacitor voltage, curve 4(d) It is the inductor current waveform under BCM. where I o is the average value of the output current, I peak is the maximum output current, I val is the minimum output current, ΔI o is the amount of output current ripple. at t on Time, the switch tube is turned on, the reference capacitor discharges, its voltage drops rapidly, and the inductor current rises to I peak , the switch is turned off. At this time, the switch tube turns from on to off, and the output current reaches the peak value I peak . at t off During the time, the voltage-controlled current source charges the reference capacitor, and the reference capacitor voltage rises to U C (U C is the reference capacitor voltage reference value), the switch tube is tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com