Liquid ring pumping and reclamation systems in a processing environment

A liquid ring pump, recovery system technology, applied in the field of chemical management, can solve the problem of not being able to adequately control multiple process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention present methods and chemical management systems for controlling aspects of fluid delivery and / or recovery.

[0024] System Overview

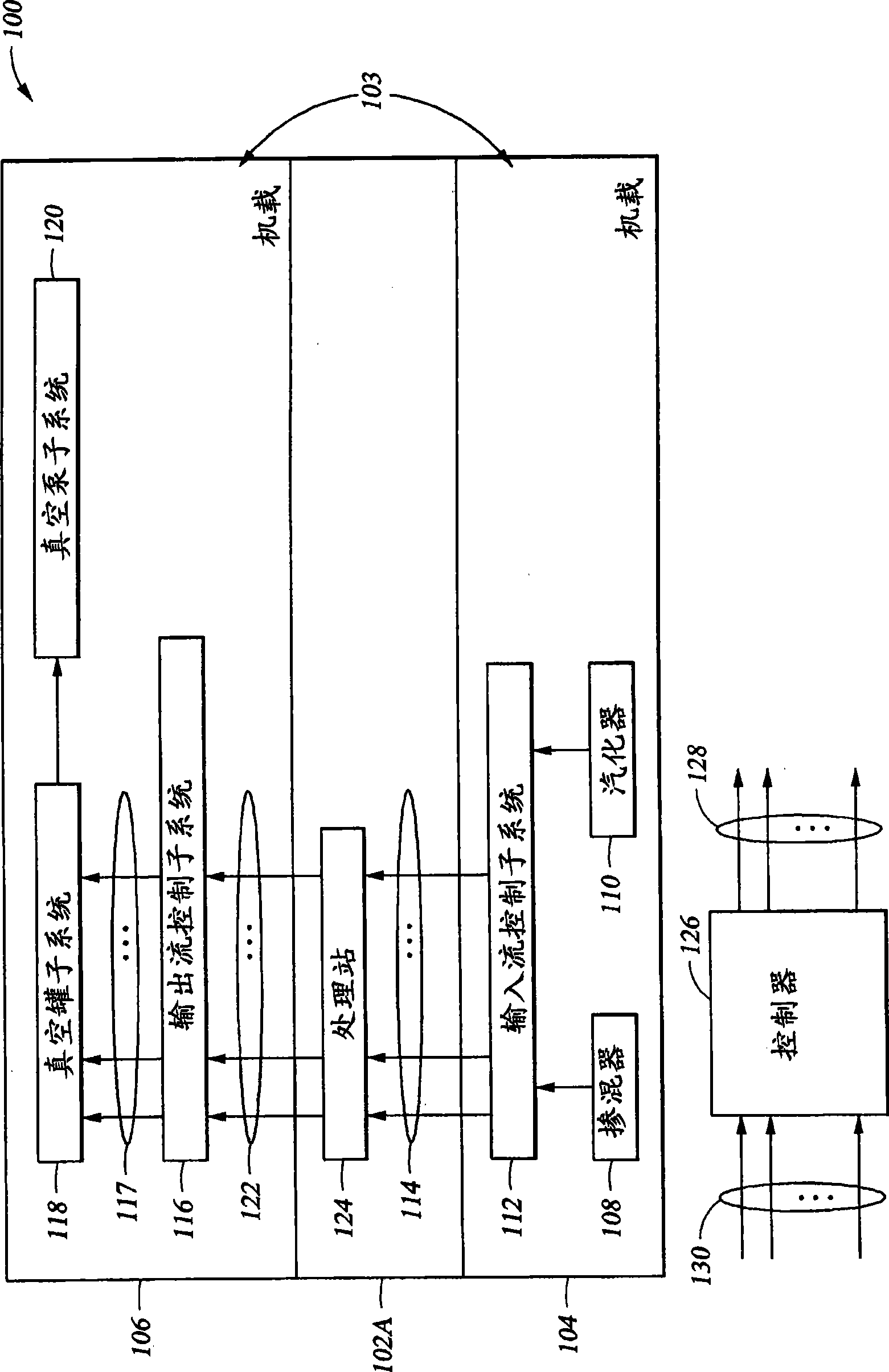

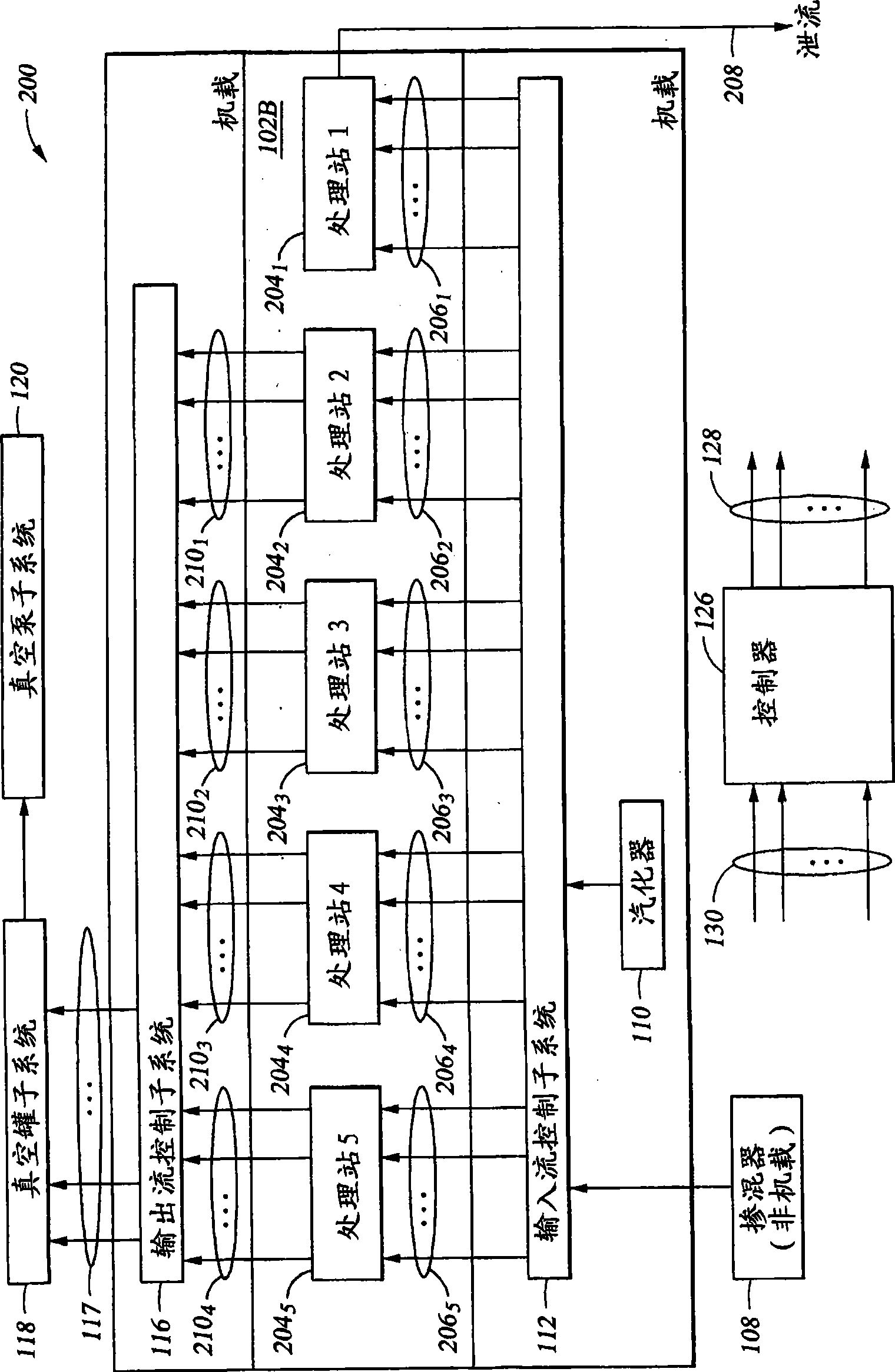

[0025] figure 1 One embodiment of a processing system 100 is shown. Generally, the processing system 100 includes a processing chamber 102 and a chemical management system 103 . According to one embodiment, the chemical management system 103 includes an input subsystem 104 and an output subsystem 106 . It is contemplated that any number of components of subsystems 104 , 106 may be onboard or offboard relative to process chamber 102 . In this context, "onboard" means that the subsystem (or its components) is integrated in a Fab (clean room environment) with the processing chamber 102, or more generally with the processing tool of which the processing chamber 102 is a part; while "Off-board" means that the subsystem (or components thereof) is separate and located at a distance from the process cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com