Method and system for testing indirect bandgap semiconductor devices using luminescence imaging

A technology of semiconductor and light-emitting images, which is applied in semiconductor devices, semiconductor/solid-state device testing/measurement, photometry, etc., and can solve problems such as reducing the efficiency of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of methods and systems for electroluminescent and photoluminescent imaging of indirect bandgap semiconductor devices are described below. Although certain embodiments have been described with specific reference to solar cells, it is not intended that the invention be limited to such devices, as the principles of the invention have general applicability to optoelectronic devices and / or semiconductor devices and structures, which may all or partially processed.

[0031] In the context of this specification, references to electrically isolated or poorly connected areas are intended to include partially electrically isolated areas within the intended meaning. For example, electrically isolated or poorly connected regions include regions that resistively couple to other regions.

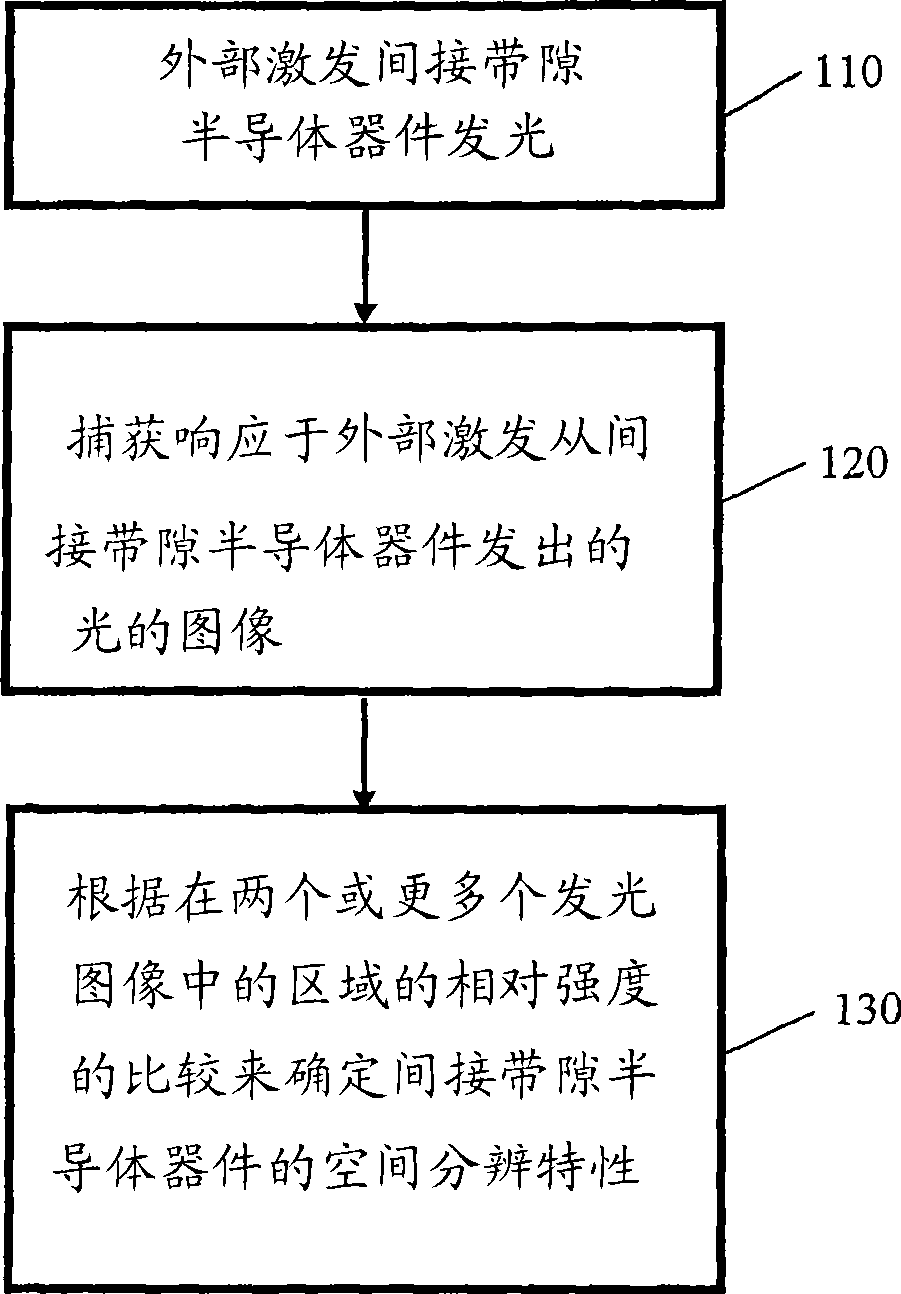

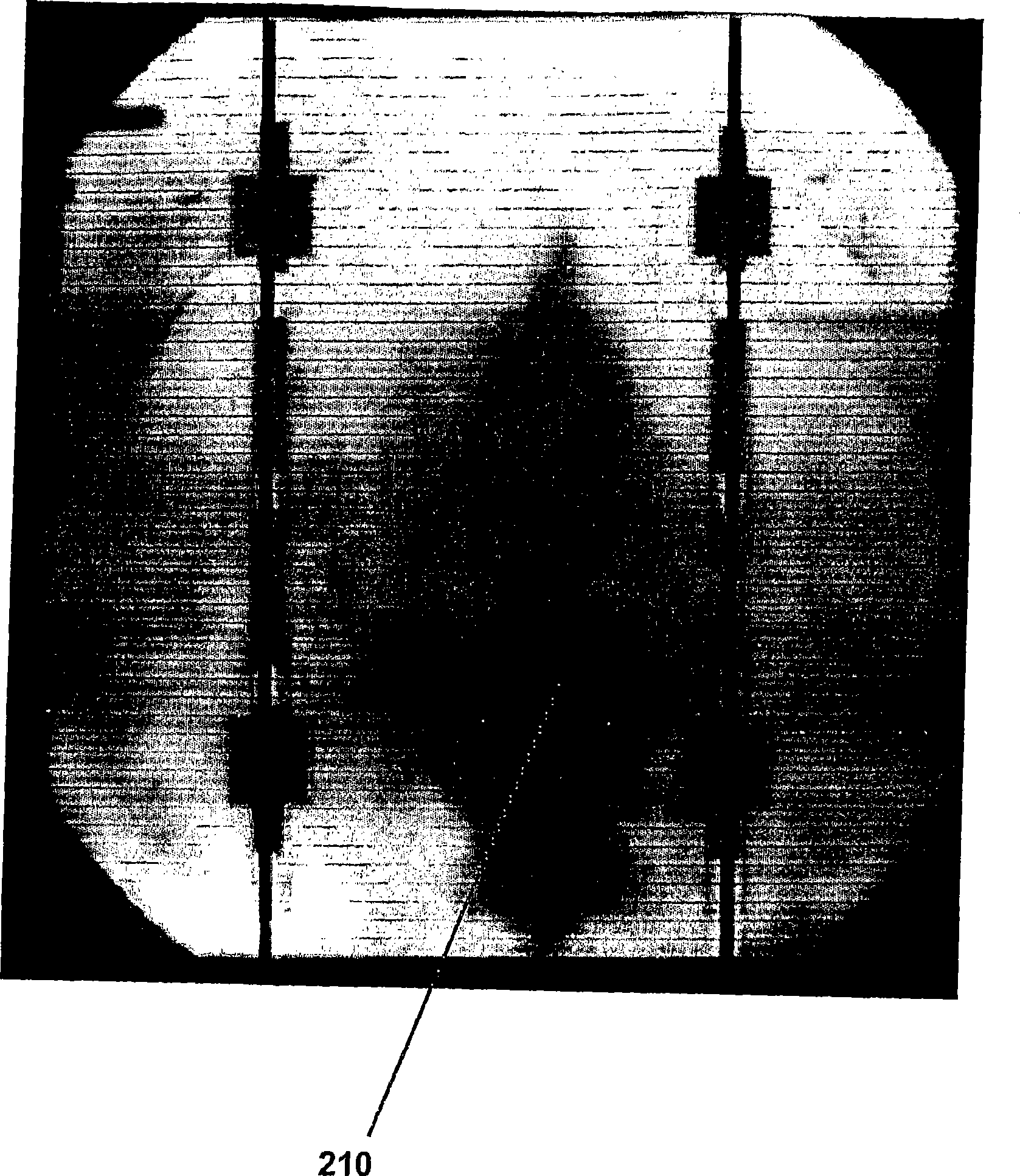

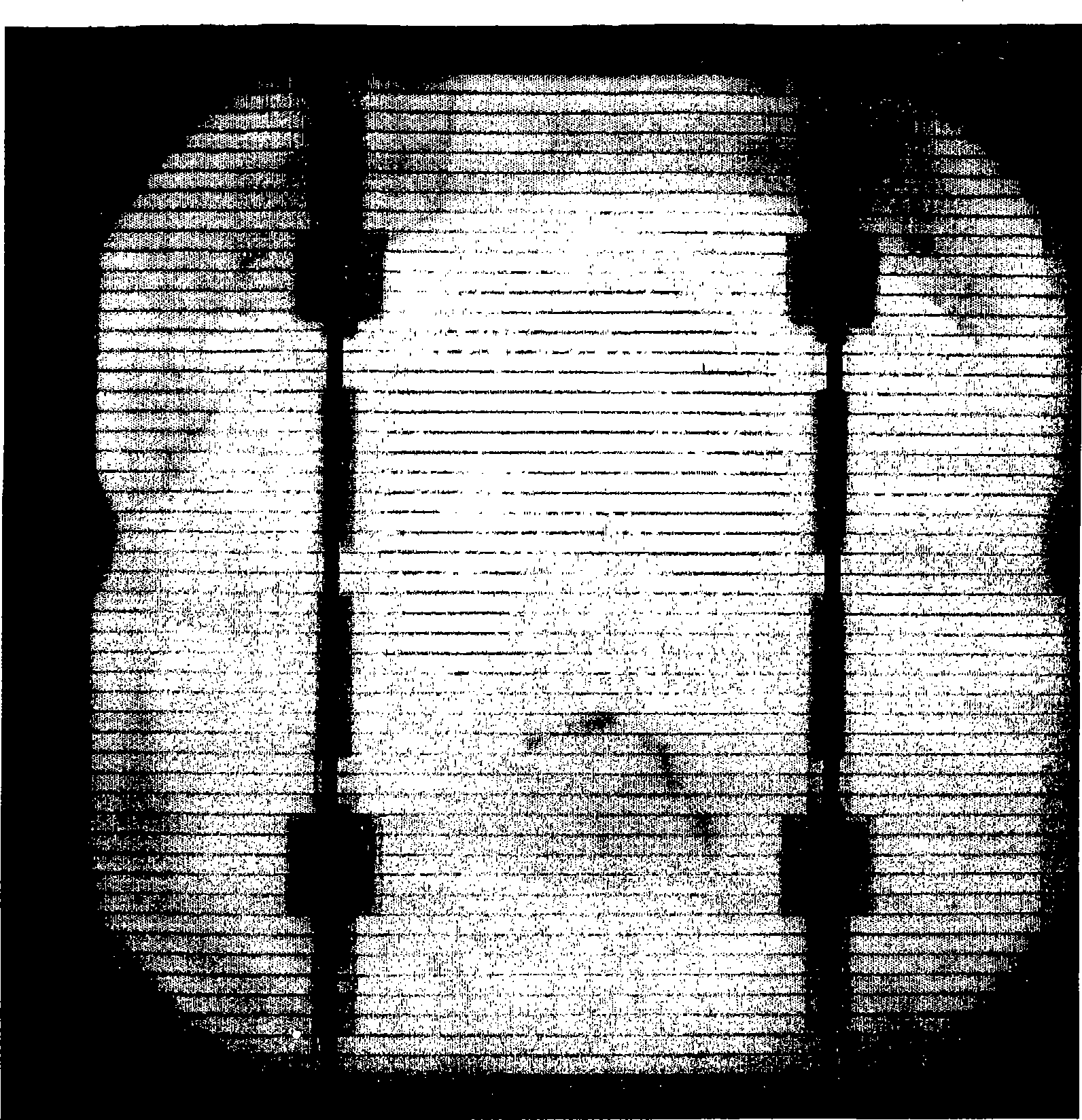

[0032] The methods used to optically inspect or test indirect bandgap semiconductor devices such as optoelectronic devices and solar cells differ in the way the devices are excited. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com