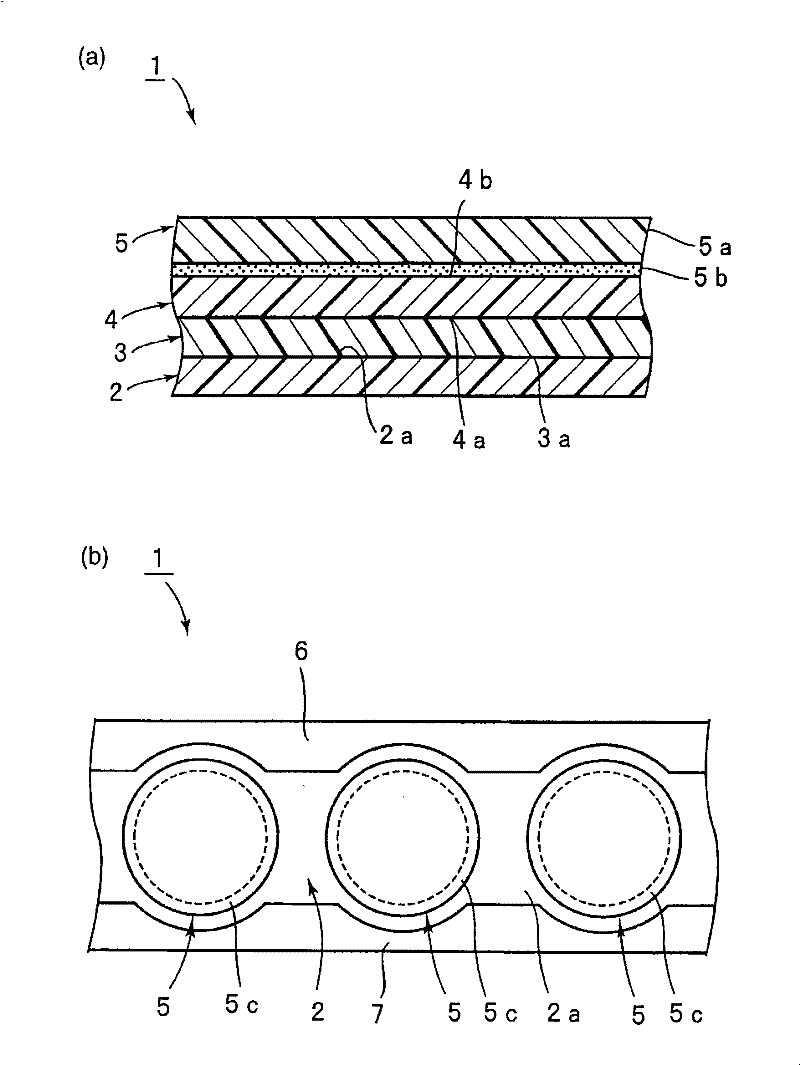

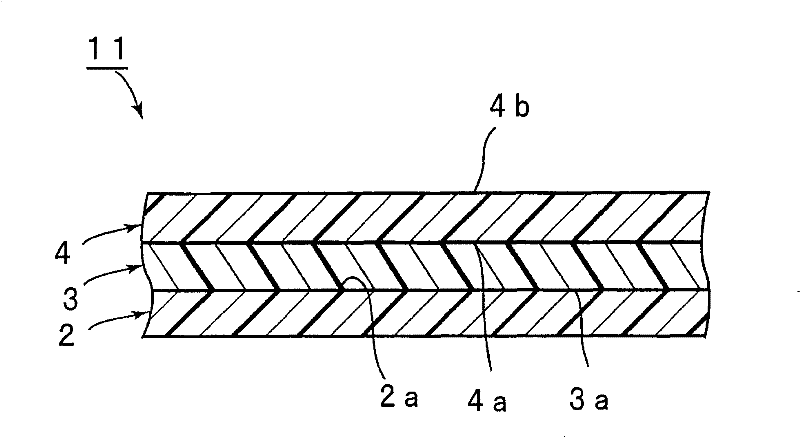

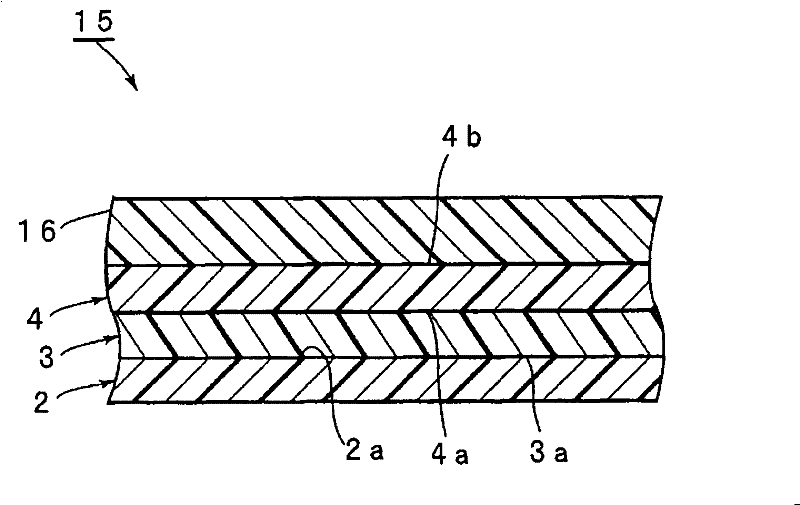

Dicing/die-bonding tape and method for manufacturing semiconductor chip

A chip bonding and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, film/sheet adhesives, etc., can solve problems such as reducing adhesion, achieve the effect of preventing damage and realizing the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0233] Mix G-2050M (manufactured by NOF Corporation, epoxy group-containing acrylic polymer, weight average molecular weight Mw 200,000) 15 parts by weight, EXA-7200HH (manufactured by Dainippon Ink Co., Ltd., dicyclopentadiene type epoxy) 70 Parts by weight, HP-4032D (manufactured by Dainippon Ink Co., Ltd., naphthalene type epoxy) 15 parts by weight, YH-309 (manufactured by Japan Epoxy Resin Company, anhydride curing agent) 38 parts by weight, 2MAOK-PW (Shikoku Chemical Industry Co., Ltd. production, imidazole) 8 parts by weight, S320 (manufactured by cisso company, aminosilane) 2 parts by weight and MT-10 (manufactured by Tokuyama company, surface hydrophobized fumed silica) 4 parts by weight, the mixture was added to the solvent The solid content was adjusted to 60% in methyl ethyl ketone (MEK) and stirred to obtain a coating liquid. This coating solution was applied on a release film to a thickness of 40 μm, and heated and dried in an oven at 110° C. for 3 minutes to form...

Embodiment 2

[0236] 4 layers of slices and die-bonding tapes were made in a manner similar to that of Example 1, except that an LDPE film (the LDPE film obtained by extruding the T-die head of Millasson (ミラソン) M12 manufactured by Mitsui Chemicals Co., Ltd., was used, Extrusion temperature 200° C., film thickness 50 μm) was used as a non-adhesive film.

Embodiment 3

[0238] Four-layer slices and die-bonding tapes were produced in a manner similar to that of Example 1, except that a T-die head of HI-ZEX (ハイゼツクス) 3300F manufactured by a primepolymer (primepolymer) company was used. The obtained HDPE film was extruded (extrusion temperature: 200° C., thickness: 50 μm) as a non-adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com