Crucible pot for manufacturing ultra-fine continuous glass fiber

A glass fiber and crucible technology, which is applied in the field of crucibles for ultra-fine continuous glass fiber production, can solve the problems of complex design, large platinum alloy consumption, and difficult processing, and achieve the goals of reducing erosion, prolonging residence time, and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

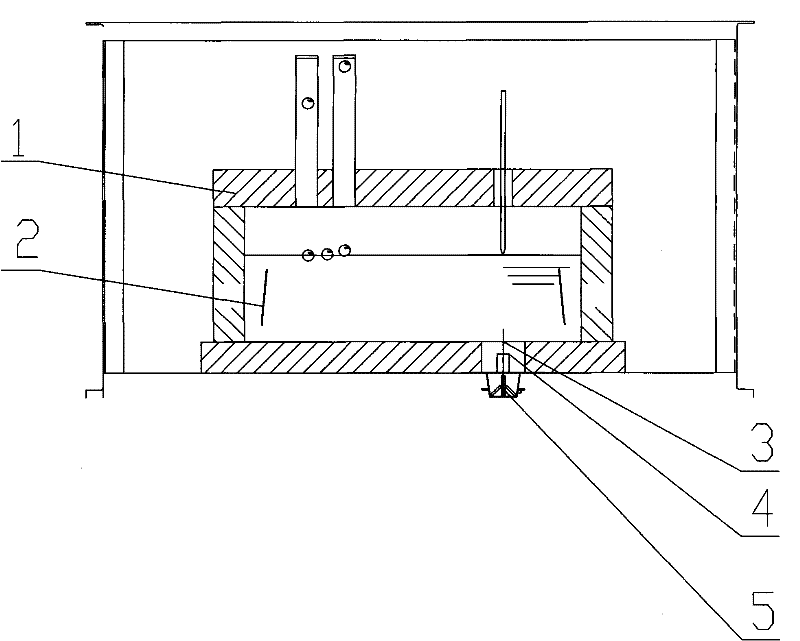

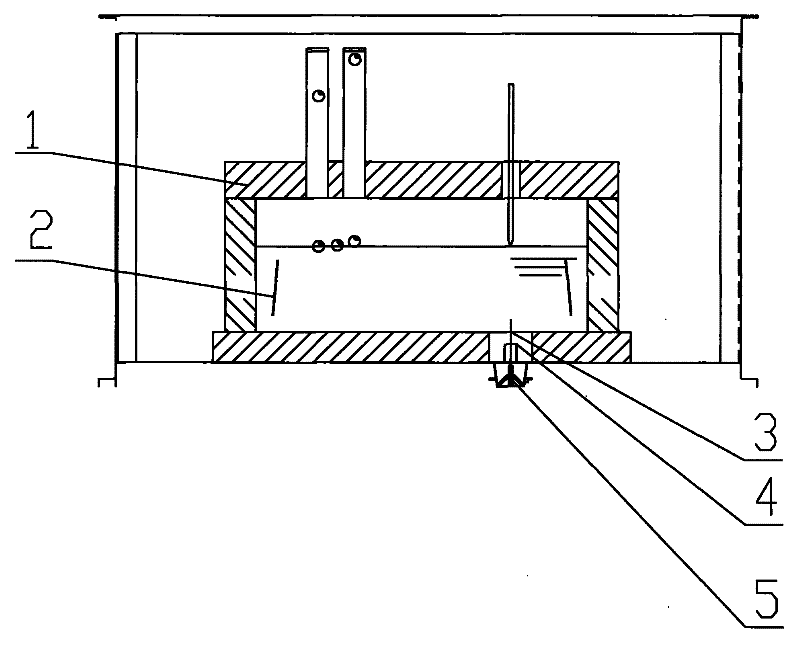

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] see figure 1 , the present invention uses refractory materials to build the crucible 1, and the effective volume of the crucible 1 is 0.5 to 1.5 times of its output. The two plate-shaped lead-in electrodes 2 arranged in the crucible are rectangular or trapezoidal. After the current is introduced into the glass melt through the lead-in electrodes, the glass ball can be melted by the melt itself acting as a resistor to energize and generate heat. The plate electrode 2 is arranged on both sides of the crucible along the center line of the crucible, the bottom of which is 50-100mm away from the upper surface of the crucible bottom brick, and the angle with the vertical line of the bottom brick is 15°-25°, and the distance between the two plate electrodes is 0.8 to 0.9 times the length of the crucible. Through this arrangement, the power line can be arranged in the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com