Support pin

A technology of support pins and arms, applied in optics, instruments, nonlinear optics, etc., can solve the problems of time-consuming and labor-intensive, difficult dismantling, etc., and achieve the effects of reducing volume, solving cost consumption, and reducing the cost of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

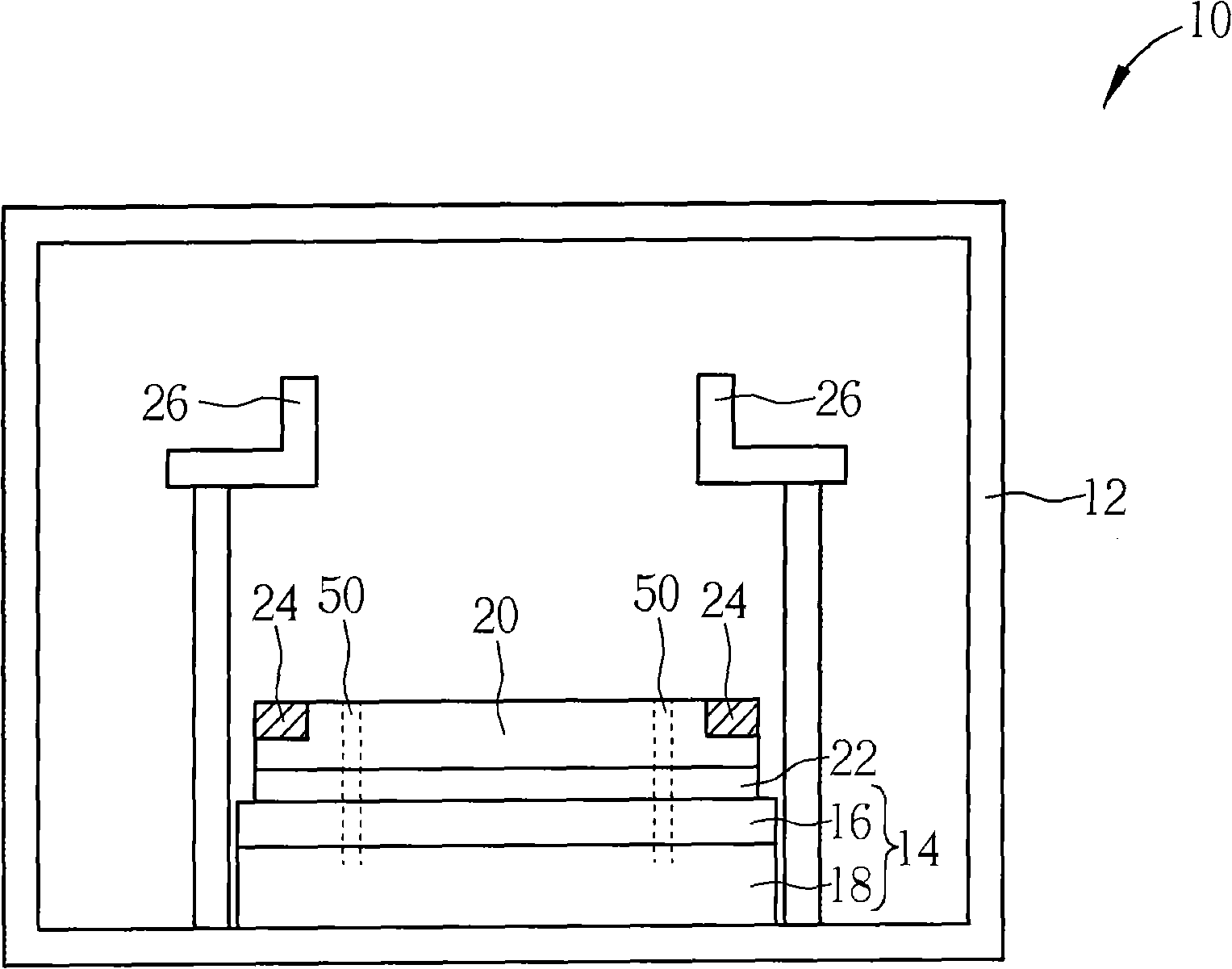

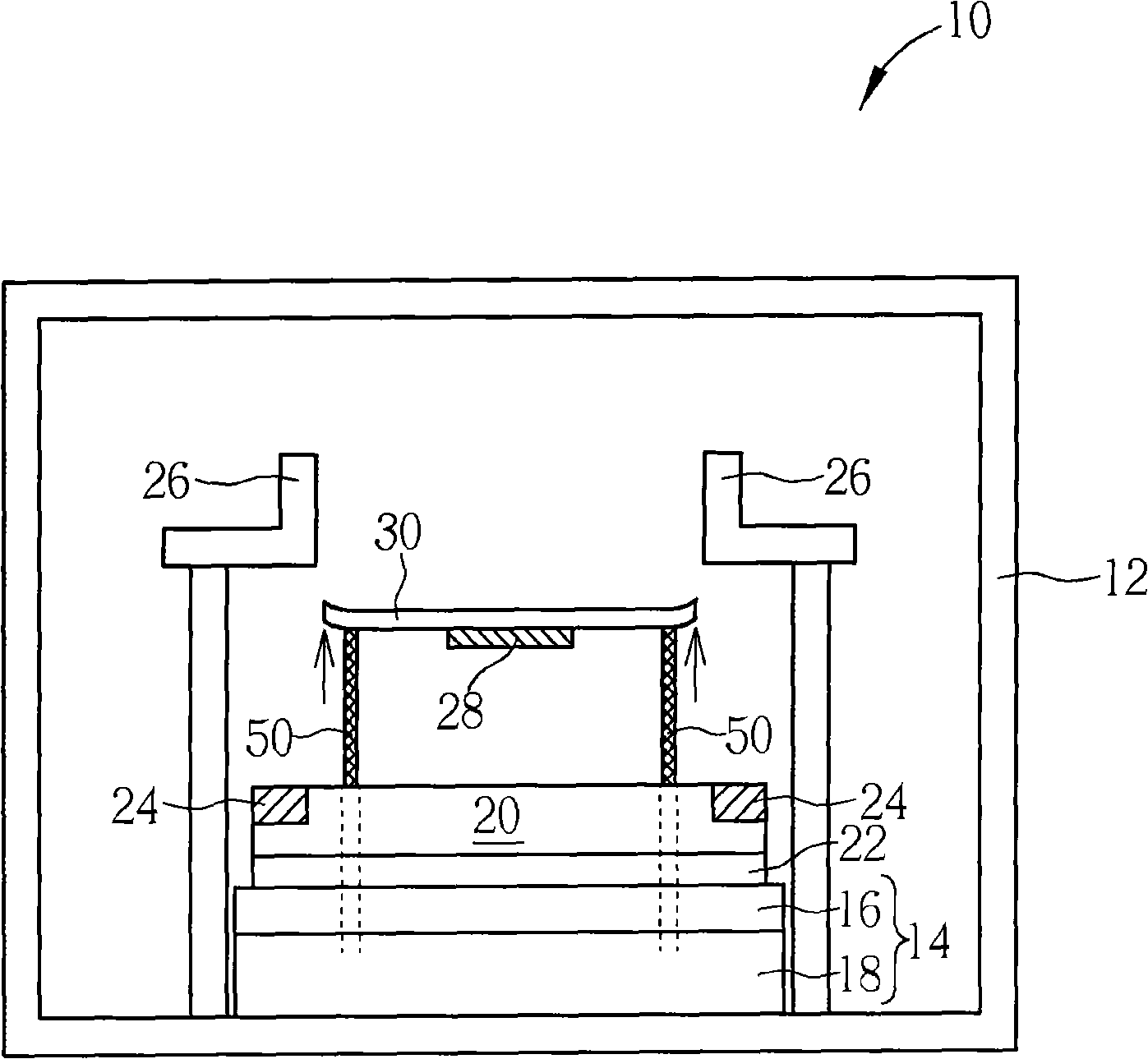

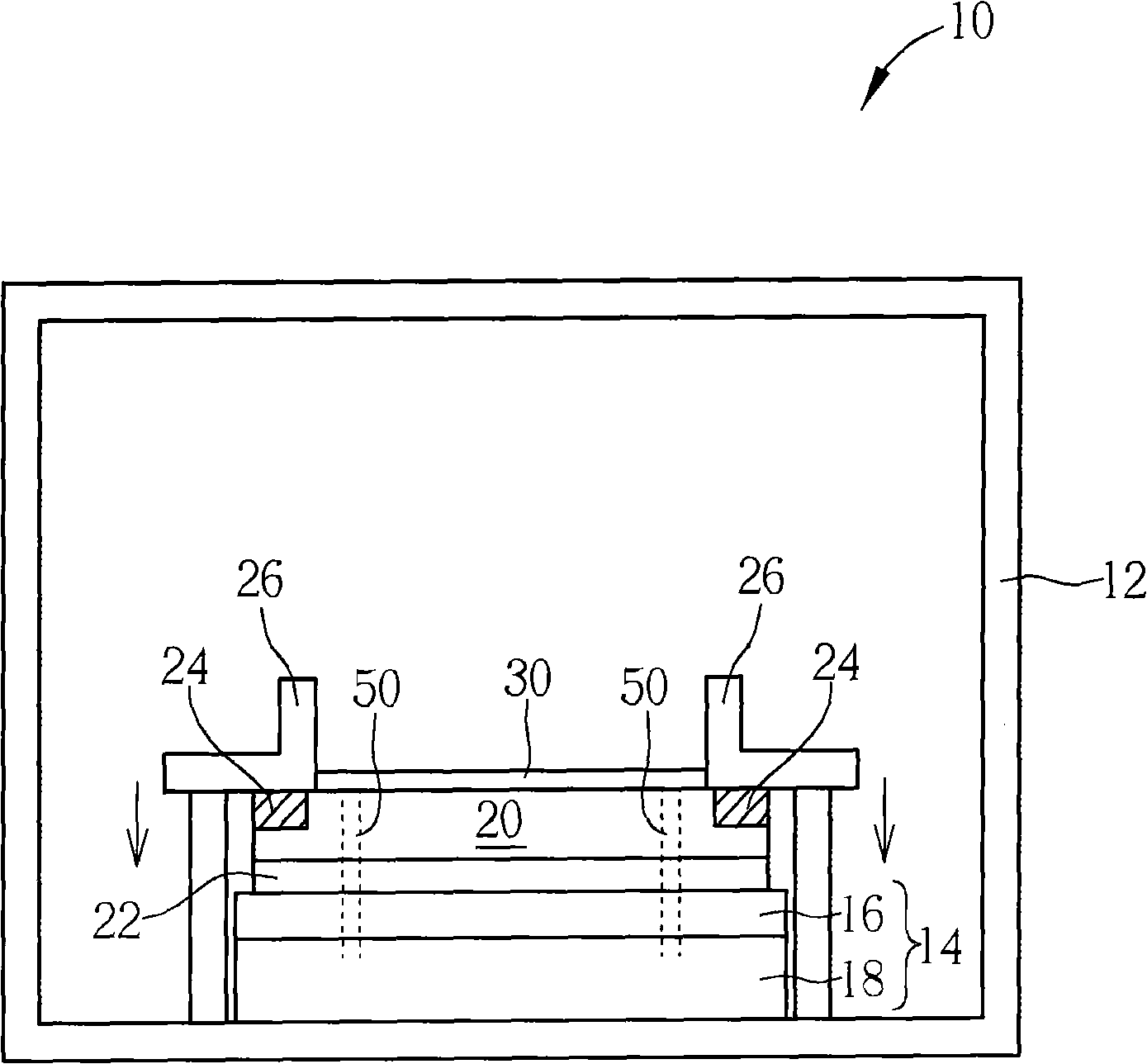

[0027] Please refer to Figure 6 to Figure 9 , FIG. 6 is a schematic diagram of a support pin in a preferred embodiment of the present invention, Figure 7 to Figure 9 It is an exploded structure diagram of various parts of the support pin in the preferred embodiment of the present invention. As shown in Figure 6, the support pin 60 of the preferred embodiment of the present invention is a three-piece structure, which includes three parts such as a body 62, an arm 64 and a solid lock seat 66, and all The detachable way is vertically socketed and combined to fit and fix each other, and connected to become the support pin 60 of the present invention. Wherein, according to the vertical direction, the support arm 64 is detachably disposed on the top of the locking seat 66 , and the body 62 is detachably disposed on the top of the support arm 64 .

[0028] like Figure 7 As shown, the bottom end 67 of the locking seat 66 has a groove 63, and the inner wall of the groove 63 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com