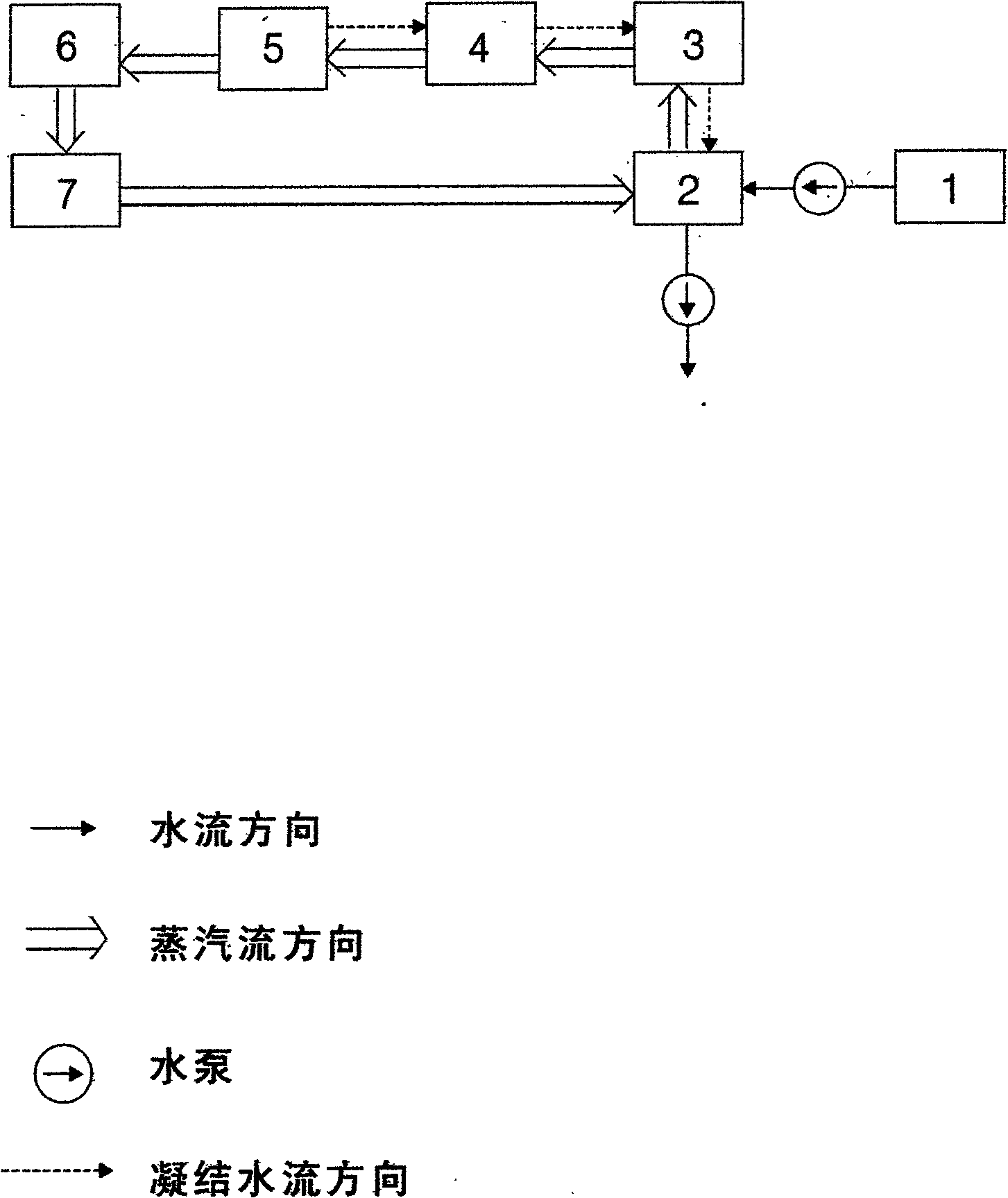

Novel geothermal power plant process flow

A technology of geothermal water and heat, applied in geothermal power generation, geothermal energy systems, machines/engines, etc., can solve problems such as low thermal efficiency, waste of natural resources, and high temperature of geothermal water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The geothermal water is pumped to the multifunctional vacuum circulating water tank. Since the temperature of the multifunctional vacuum circulating water tank is controlled below 5°C, the heat with a temperature higher than 5°C will turn into steam and be recovered by the multifunctional steam recovery bin.

[0008] The steam recovered from the multi-functional steam recovery chamber is transformed into a supercritical liquid by the medium-pressure steam chamber, high-pressure steam chamber, and supercritical pressure cylinder, and then sprayed on the steam turbine to expand rapidly, turning into high-temperature and high-pressure water vapor to drive the steam turbine to generate electricity. The low-temperature and low-pressure water vapor after work is sent to the multifunctional vacuum circulation water tank by the air extractor. The water vapor that does not turn into water is forcibly sent to the multi-functional steam recovery bin by multiple powerful air extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com