Thermal storage burning four-way valve

A regenerative combustion and four-way valve technology, applied to multi-way valves, valve devices, engine components, etc., can solve the problems of high cost, non-continuous operation, high hardness and difficult processing of four-way valves, etc., and achieve convenient operation and processing Convenience and the effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

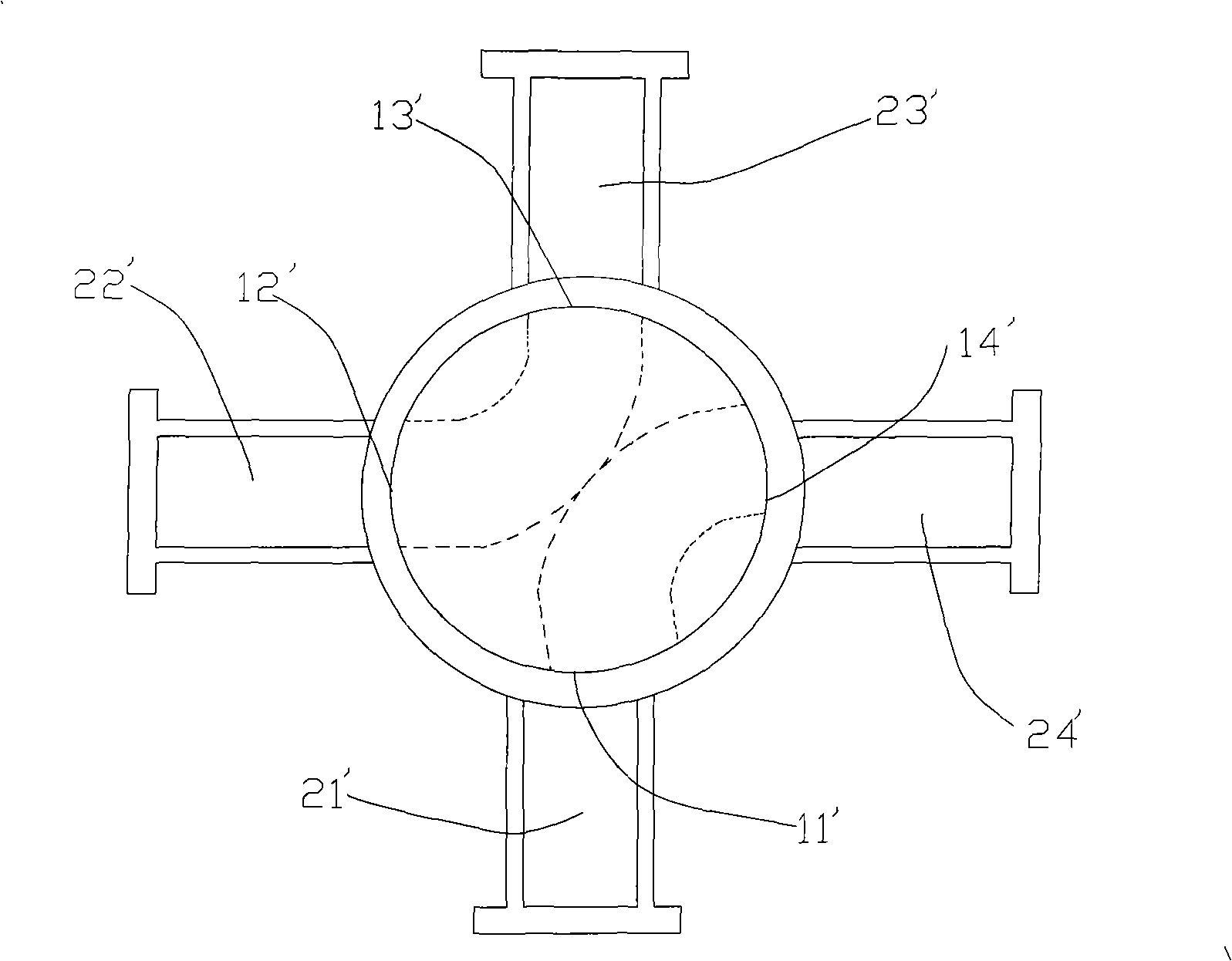

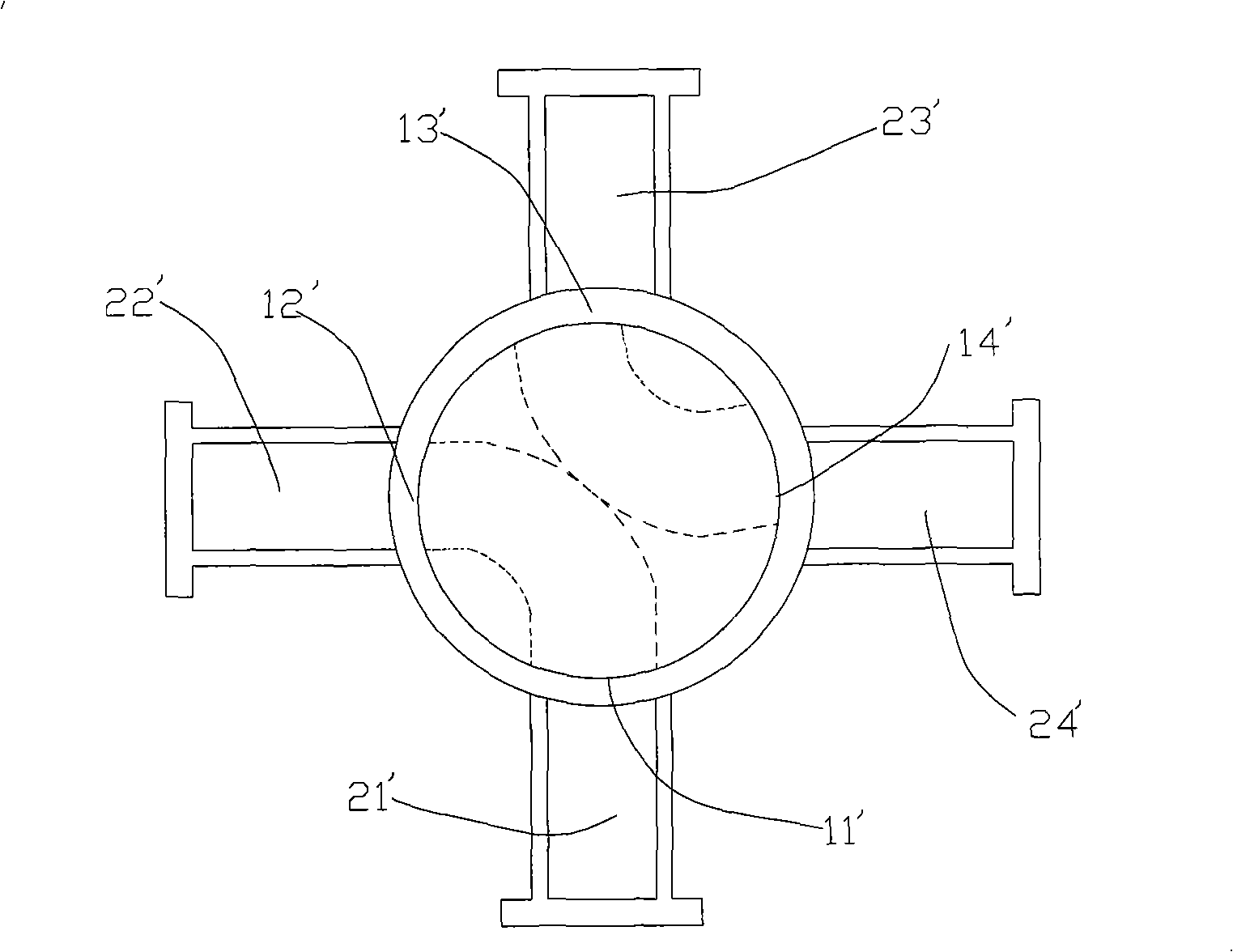

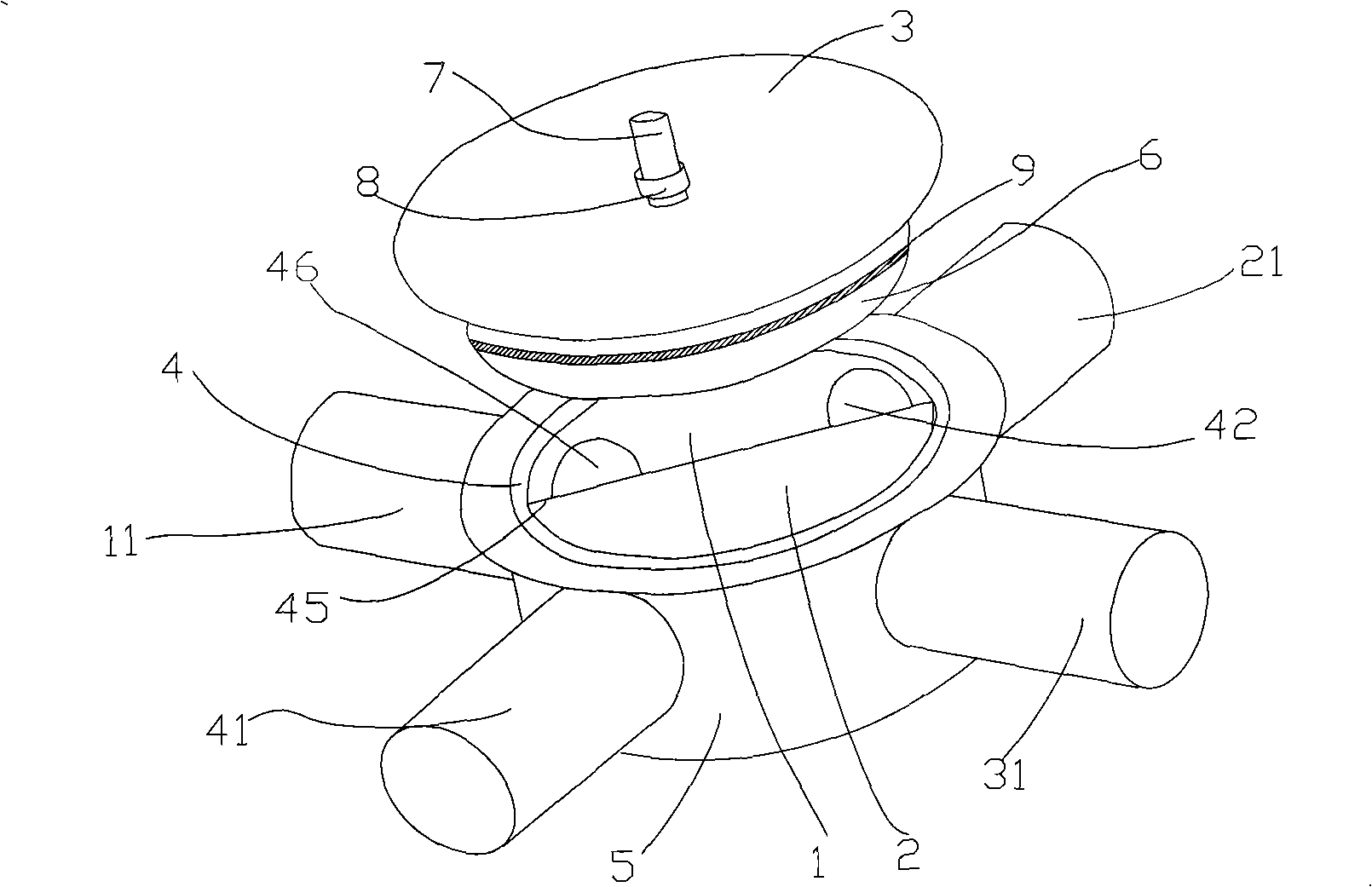

[0020] see image 3 arrive Figure 5 As shown, a regenerative combustion four-way valve includes a container body 5, the wall thickness of which is more than 3 mm, and four connecting pipes (11, 21, 31) are symmetrically connected on the outer surface of the container body 5. , 41), the connecting pipe (11, 21, 31, 41) is formed with four openings (55, 56, 57, 58) in the container body 5; the container body 5 is cylindrical, and also includes a cylindrical valve Core inner cylinder 4, the valve core inner cylinder 4 is movably nested in the container body 5, and four inner holes ( 42, 43, 44, 46), an inner cylinder cover plate 6 is provided on the valve core inner cylinder 4; a partition 45, the partition 45 is located in the inner cylinder 4, and the valve core inner cylinder 4 is divided into Two symmetrical parts (1, 2) that are not connected; a cover plate 3, the cover plate 3 is arranged on the container body 5 on the inner cylinder cover plate 6; a rotating shaft 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com