Method for detecting red phosphorus content in electronic product by gravimetric method

A technology of electronic products and gravimetric method, which is applied in the field of measuring red phosphorus content in electronic products by gravimetric method, can solve problems such as endangering human health, and achieve the effects of reliable method, easy implementation, and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

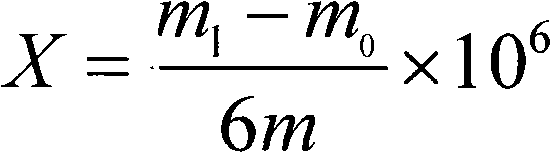

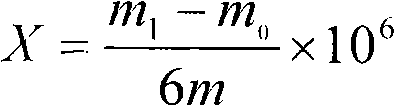

Method used

Image

Examples

Embodiment 1

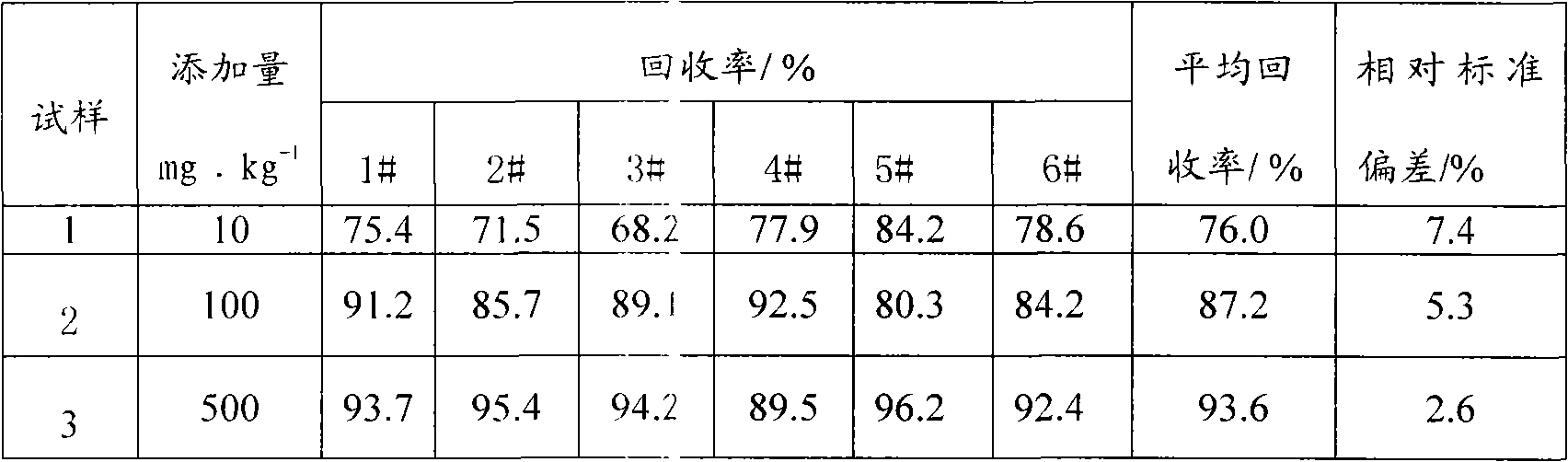

[0010] Example 1: Detection of the precision and recovery rate of red phosphorus content in plastics

[0011] Weigh 10 g of the sample pulverized by the freeze pulverizer (accurately weighed to 0.0001 g), put it into a gas generating bottle, add 100 mL of 40% sodium hydroxide solution preheated to 50 ° C, and connect the nitrogen blowing device. The generated gas was introduced into 50 mL of 5% silver nitrate solution, and nitrogen was blown for 10 minutes. Then use a glass crucible with a constant weight in a constant temperature drying oven at 105°C±2°C to filter the silver nitrate solution. After filtering the supernatant, transfer all the precipitated residue to the filter with a small amount of water. Dry the filter with residue in a constant temperature drying oven at 105°C±2°C for 1 hour, take it out and move it into a desiccator, cool to room temperature, and weigh. Repeat drying, cooling, and weighing until the mass difference between the two weighings is ≤0.2mg.

...

Embodiment 2

[0023] Embodiment 2: Detect the precision and the rate of recovery of red phosphorus content in the resin:

[0024] Weigh 10 g of the sample pulverized by the freeze pulverizer (accurately weighed to 0.0001 g), put it into a gas generating bottle, add 100 mL of 40% sodium hydroxide solution preheated to 50 ° C, and connect the nitrogen blowing device. The generated gas was introduced into 50 mL of 5% silver nitrate solution, and nitrogen was blown for 10 minutes. Then use a glass crucible with a constant weight in a constant temperature drying oven at 105°C±2°C to filter the silver nitrate solution. After filtering the supernatant, transfer all the precipitated residue to the filter with a small amount of water. Dry the filter with residue in a constant temperature drying oven at 105°C±2°C for 1 hour, take it out and move it into a desiccator, cool to room temperature, and weigh. Repeat drying, cooling, and weighing until the mass difference between the two weighings is ≤0.2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com