Fuel cell system cathode inlet relative humidity control

A fuel cell system, cathode inlet technology, applied in the system field of relative humidity or dew point, which can solve the problems of hindering gas diffusion, MEA damage, limiting performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

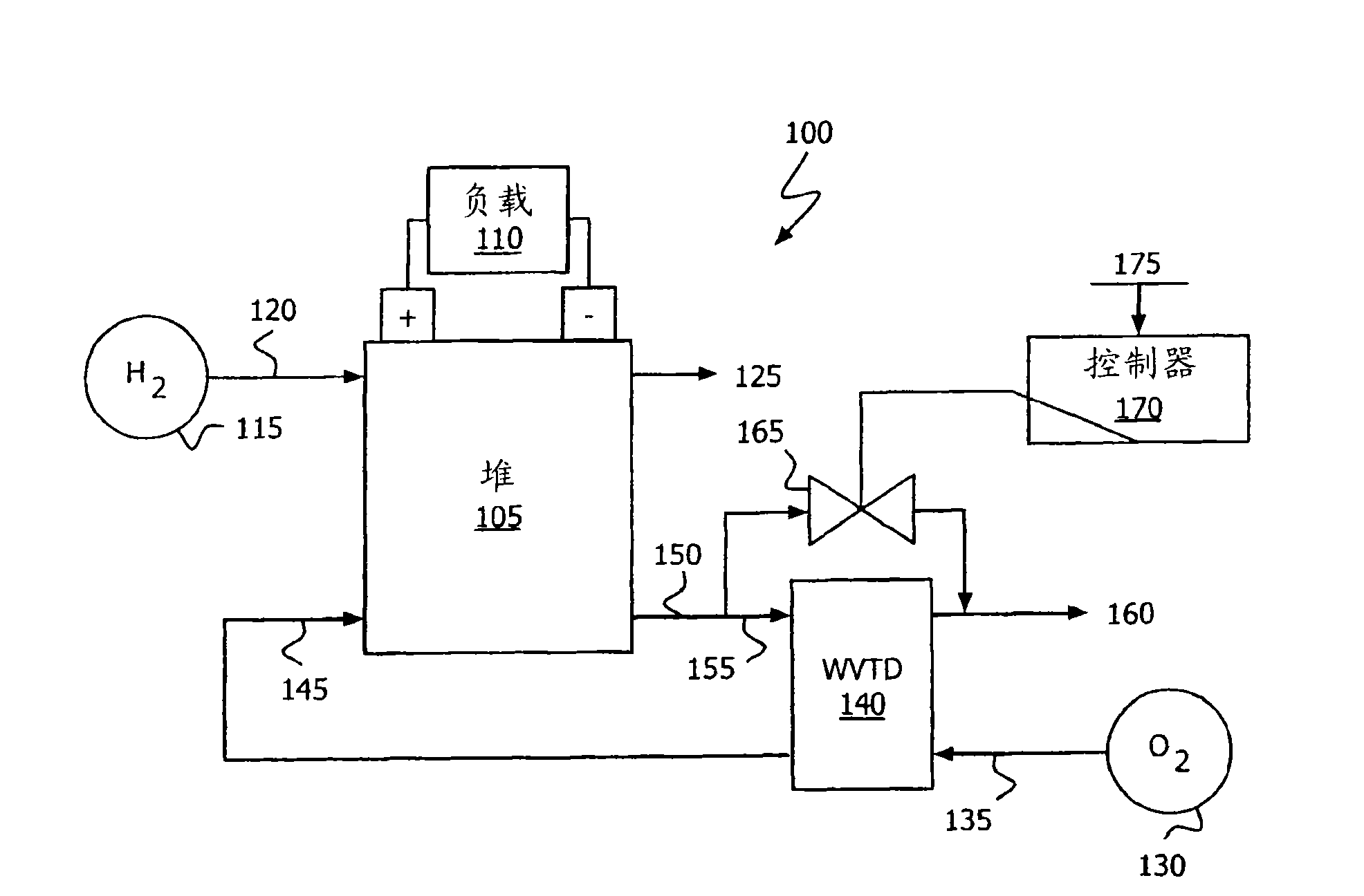

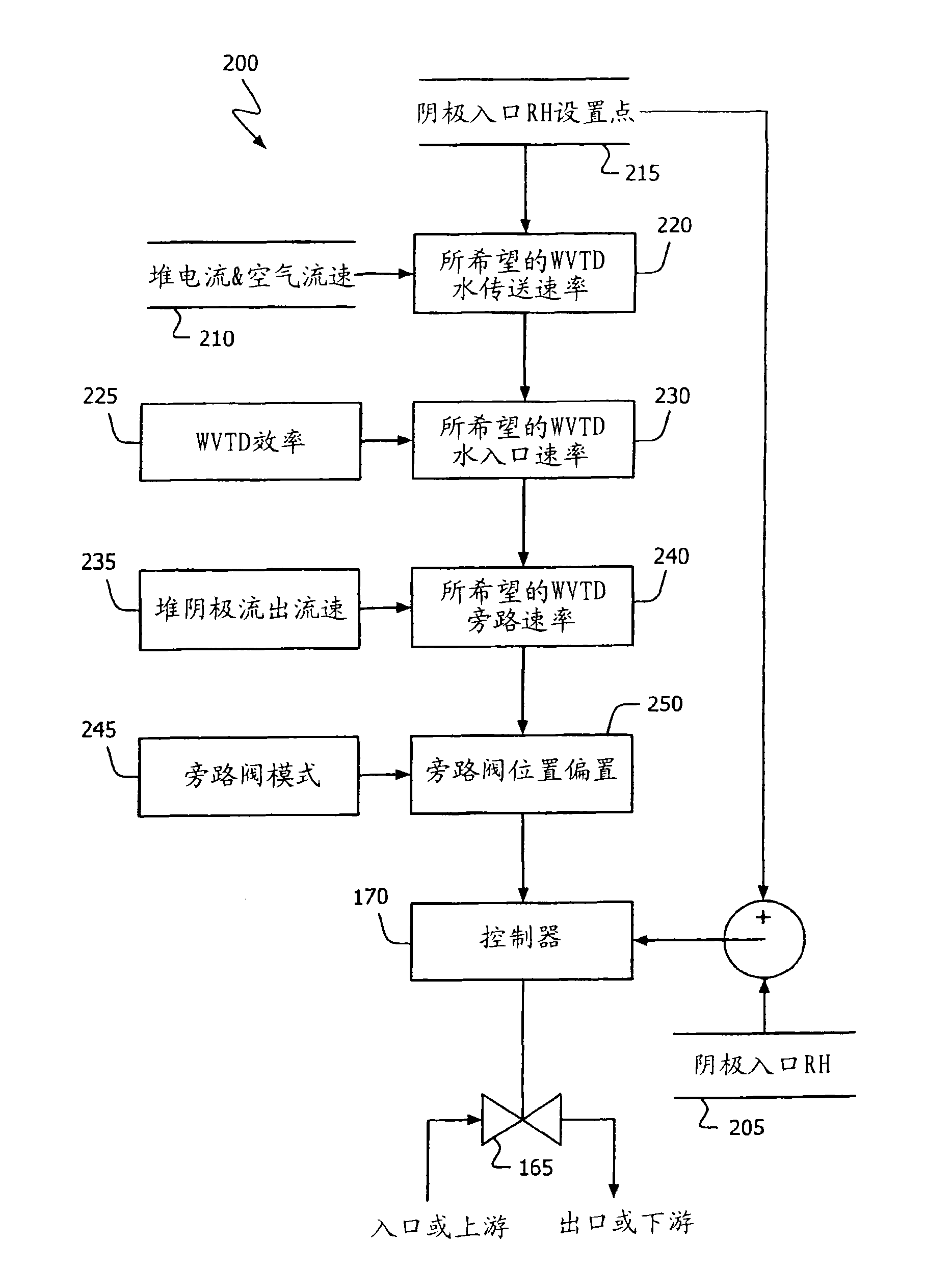

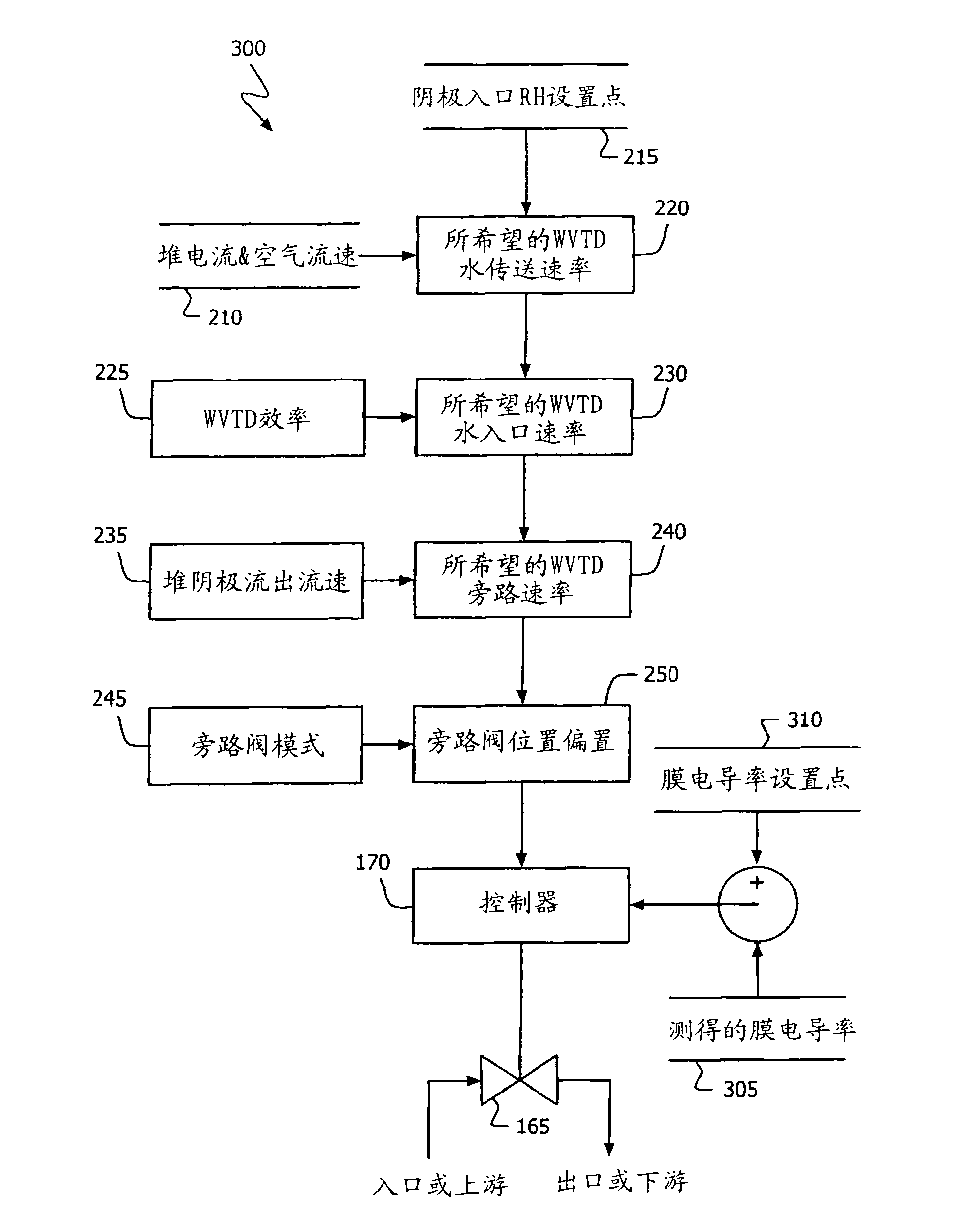

[0012] The description provided below enables one skilled in the art to make and use the invention as claimed, and is embodied in the specific example expressions discussed below, variations of which will be readily apparent to those skilled in the art. More specifically, exemplary embodiments of the present invention are described in terms of a fuel cell stack that uses gaseous hydrogen (H 2 ) as fuel, using air (O 2 and nitrogen N 2 mixture) in the form of gaseous oxygen (O 2 ) as the oxidizing agent, and a proton exchange or polymer electrolyte membrane (PEM) electrode assembly (MEA) is used. However, the claims appended hereto are not to be limited to the disclosed embodiments, but are to be accorded the widest scope consistent with the principles and features disclosed herein.

[0013] In general, fuel cell stacks operated in accordance with the present invention use a combination of sensor inputs and component patterns to controllably bypass cathode effluent processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com