Method for manufacturing commutator

A manufacturing method and commutator technology, applied in commutator manufacturing and other directions, can solve the problems of residual mica, easy to cause oblique sheets, long production cycle, etc., so as to reduce production processes and equipment, ensure forming size, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

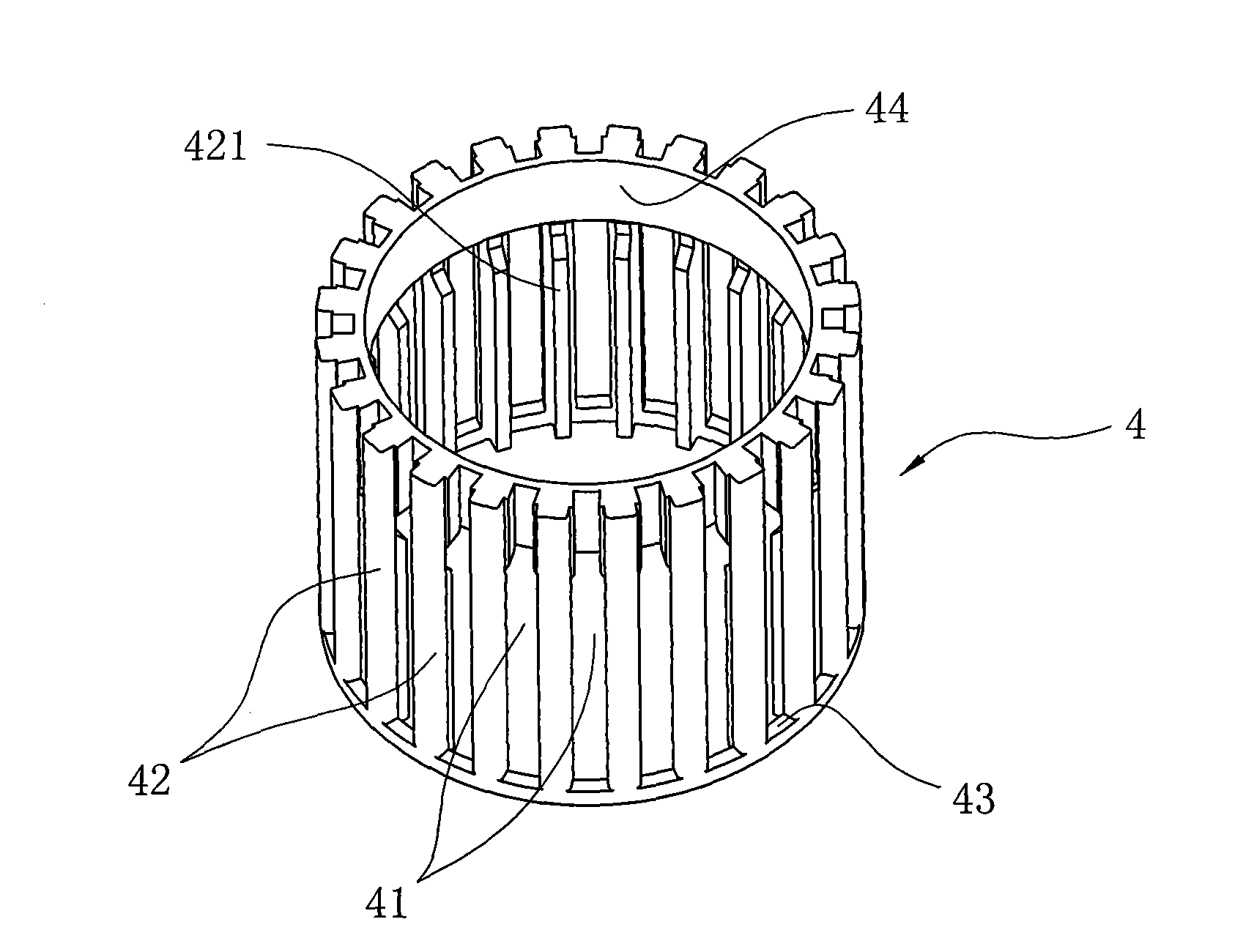

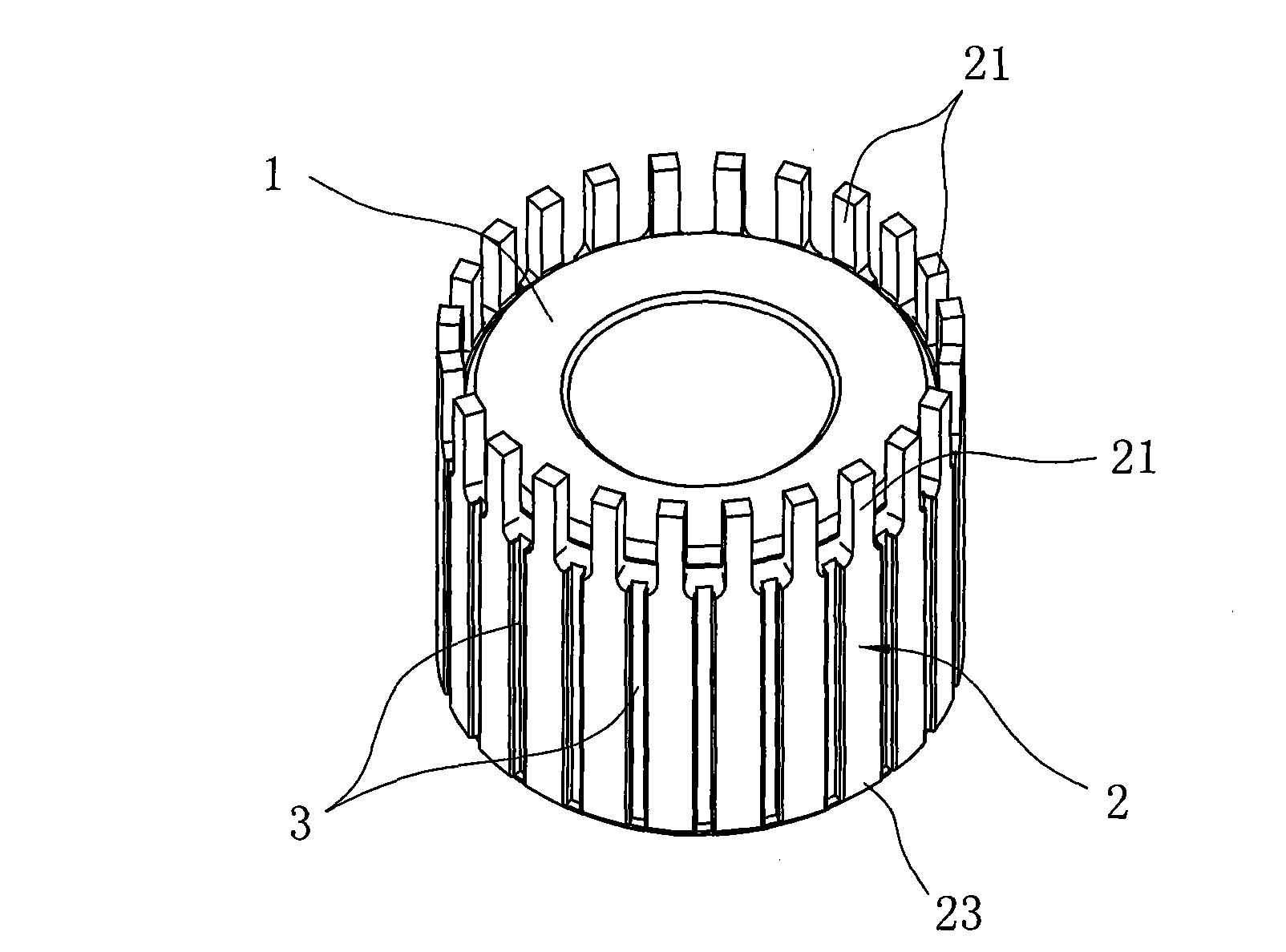

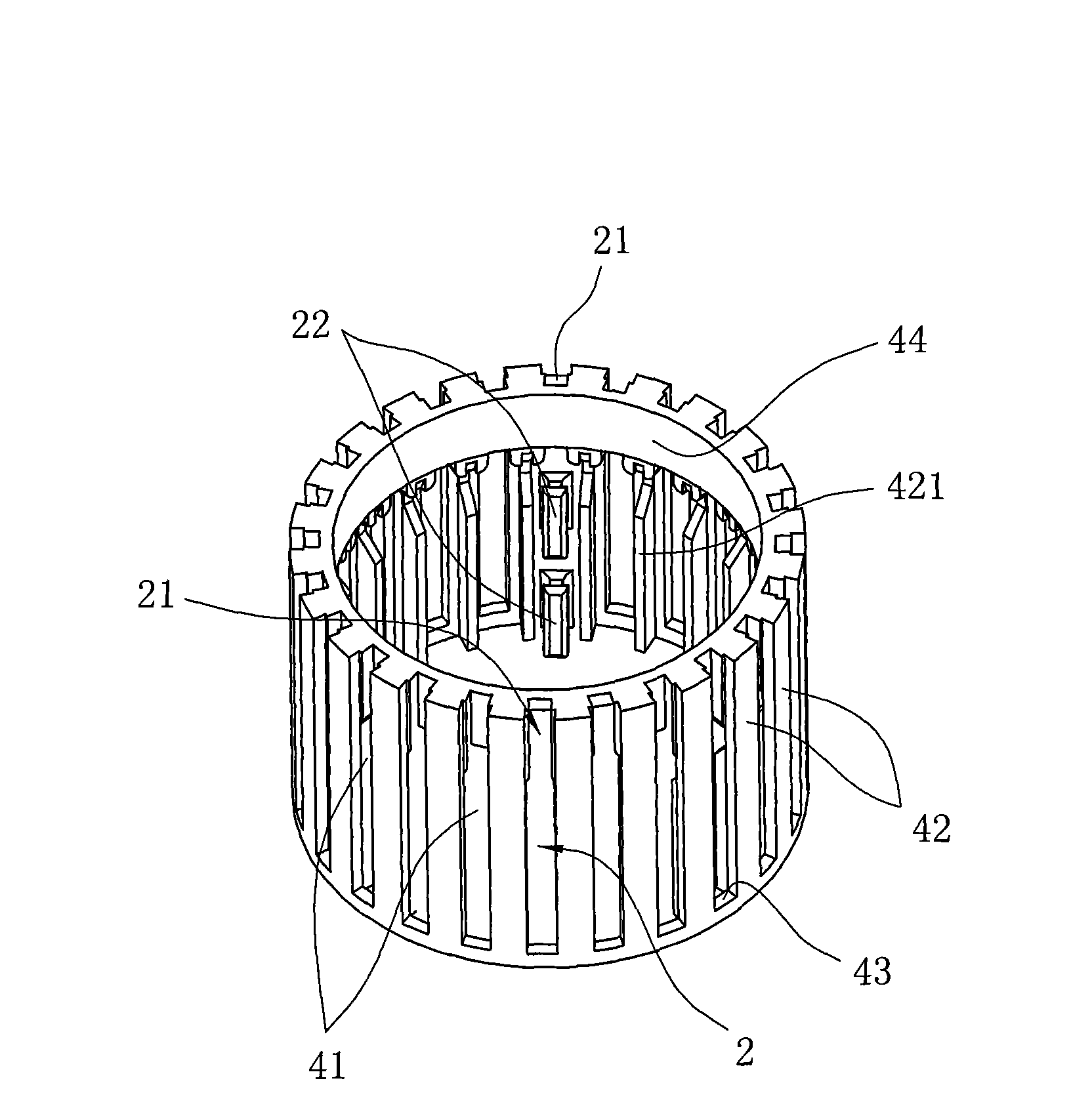

[0029] Such as Figure 1 to Figure 5 As shown, it is a specific embodiment of the present invention. The commutator of this embodiment is a hook-type commutator with a hook foot. The commutator includes a base 1 and a plurality of commutator segments 2 arranged on the circumference of the base. , there are insulating grooves 3 between the commutator pieces 2, wherein the commutator piece 2 is provided with hook feet 21 and dovetail inner ribs 22, the hook feet 21 are made by a die process, and the dovetail inner ribs 22 can expand the base body 1 and the commutator piece 2, the commutator base 1 is made of engineering plastics;

[0030] In this embodiment, the manufacturing method of the commutator includes the following process steps:

[0031] ①. Copper is used as raw material, and the material is cut and drawn into copper bars;

[0032] ②...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com