Vacuum N-shaft N-knife ring-shaped rubber cutting machine

A cutting machine and vacuum technology, applied in the field of vacuum N-axis and N-knife cutting equipment, can solve the problems of slow cutting speed of single-axis single-knife machines, inability to meet mass production, and difficulty in ensuring product accuracy, so as to improve automation and operation Excellent stability and reliability, smooth installation, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation plan

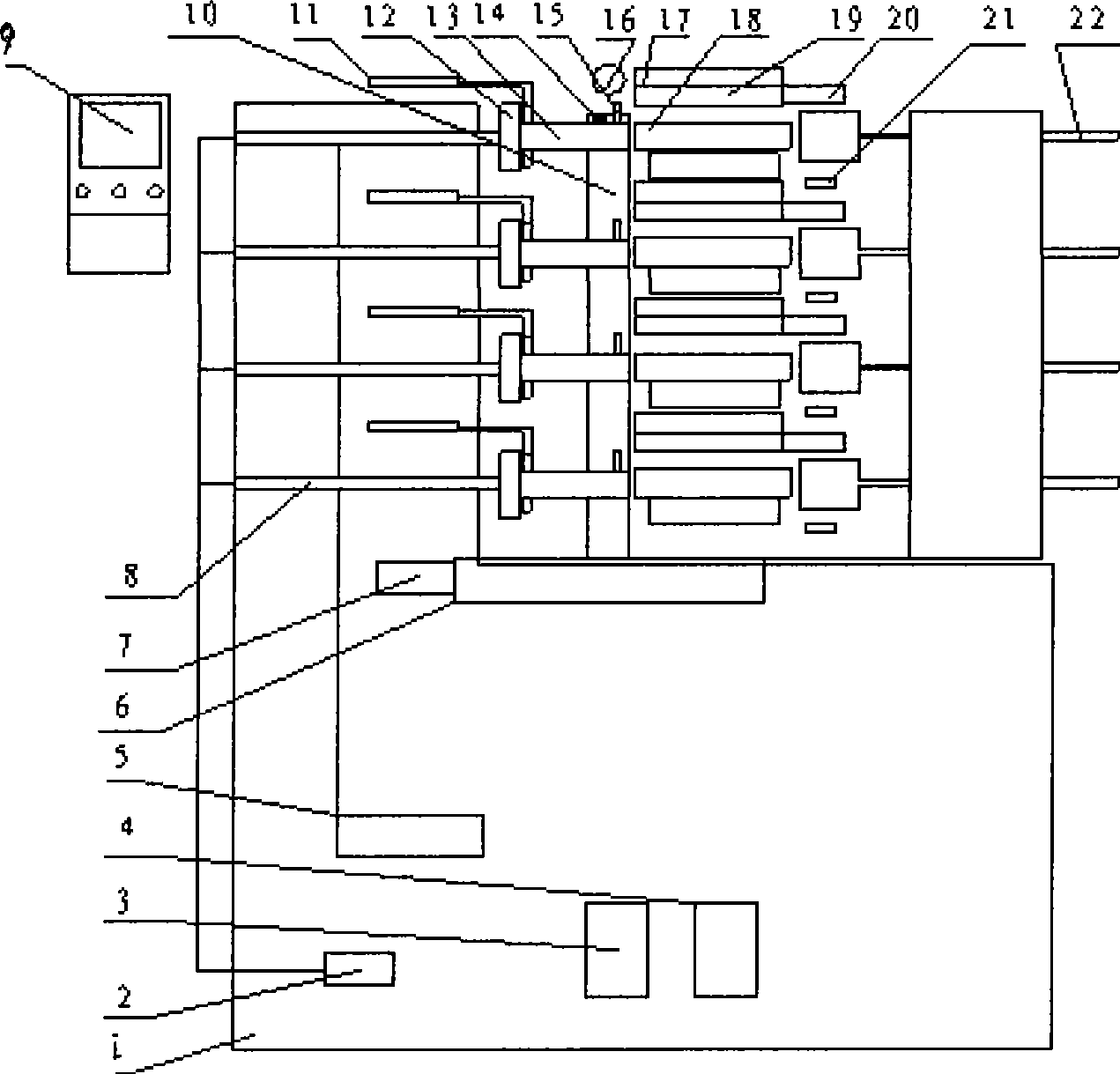

[0036] Vacuum N-axis N-knife ring-shaped rubber cutting machine, its design plan includes machine table, spindle running device, tool moving device, vacuum system device, workpiece clamping device, product automatic unloading device, program control system and other components, the manufacturing of the equipment The implementation plan is as follows: the purchase of materials and components. The main materials include: the main shaft is processed by durable and high-strength steel, and the tool is processed by hard alloy, so it has strong durability. The main components purchased include: high-precision linear table, vacuum generator, high-quality linear bearing and guide rod, servo motor and its driver, PLC, man-machine interface, etc.

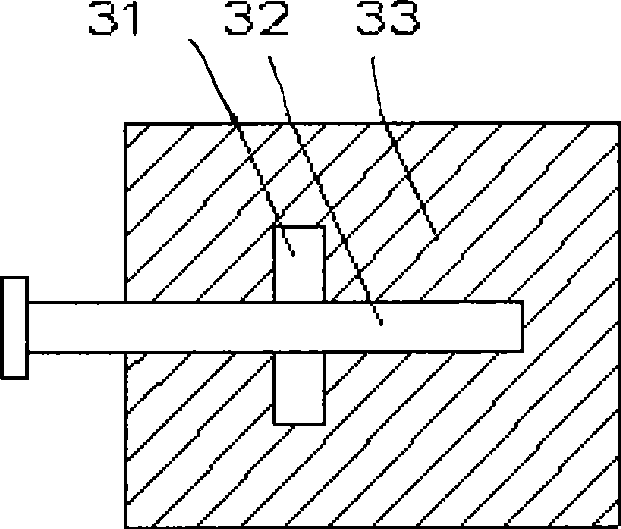

[0037] The mechanical components are precision self-processed, especially the N spindles and mandrels, cutting tools, and the machine part of the cutting machine. The installation of the whole machine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com