Spreading and cooling pot for phosphoric acid manufacture

A cooling tank, phosphoric acid technology, applied in the direction of phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of difficult filtration, difficult precipitation, precipitation, poor gypsum crystallization conditions, etc., to prolong the operation period, improve the purity, and improve the reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

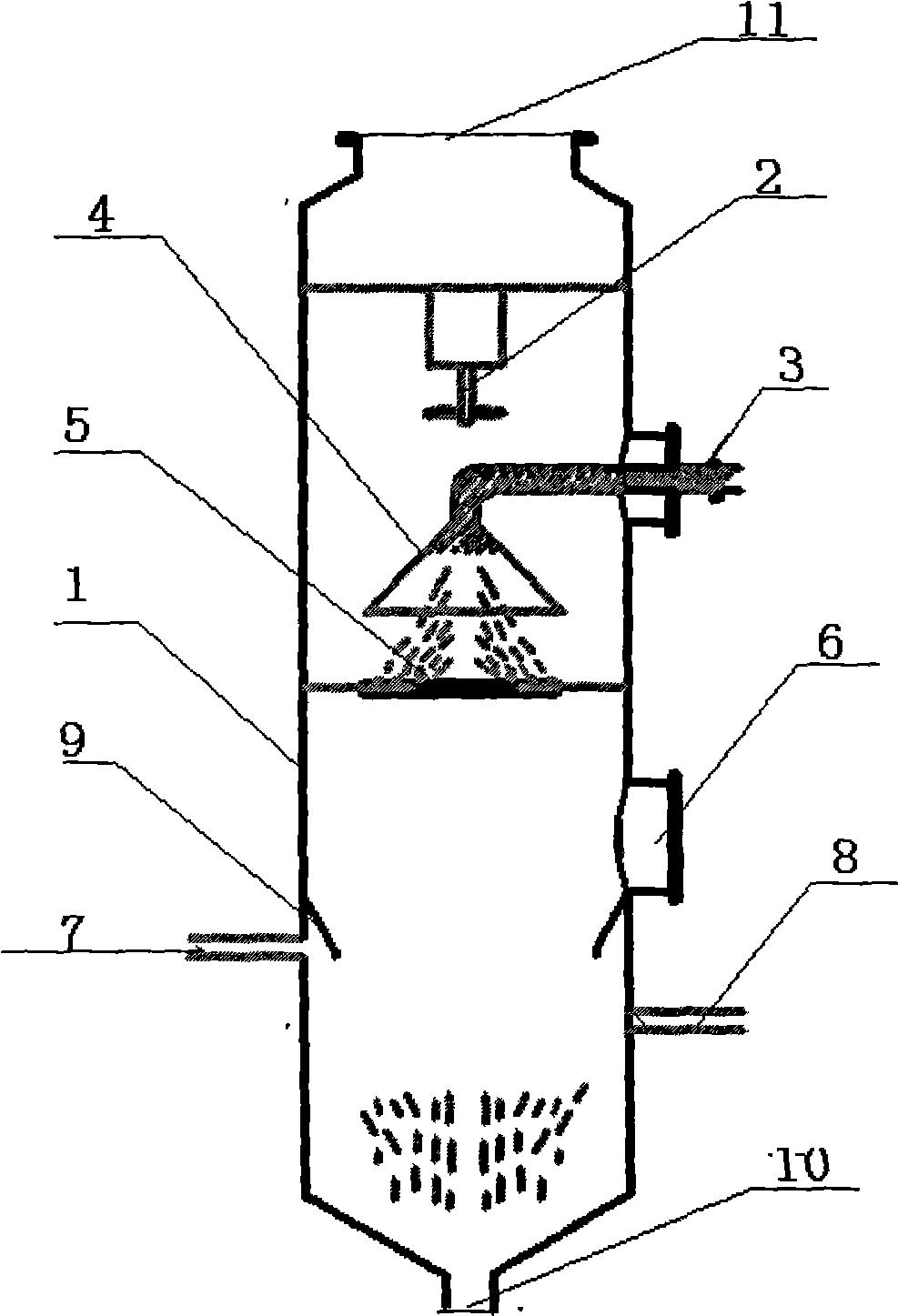

[0009] The throwing cooling tank for phosphoric acid production in the present invention consists of a tank body (1), a cooling fan (2), a hot acid inlet (3), a physalis nozzle (4), an even sprinkler baffle (5), an observation hole (6), an inlet The air outlet (7), the cold acid outlet (8), the air inlet baffle (9), the slurry discharge pipe (10) and the exhaust hole (11); the tank body (1) is a cylindrical shell, and the top is designed to install the exhaust The air hole (11), the bottom end is designed to install the sinking drain pipe (10), the upper end of the tank body axis in the tank is installed with a cooling fan (2), the cooling fan (2) is installed under the even sprinkler baffle (5), and the air inlet baffle The plate (9) is installed on the inner surface of the tank below the observation hole (6) and in front of the air inlet (7), and the air inlet (7), the observation hole (6), and the cold acid outlet (8) are installed at corresponding positions on the outer sur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap