Deep electric desalting technology for heavy inferior crude oil

A low-quality crude oil, electric desalination technology, applied in the direction of electricity/magnetic dehydration/demulsification, etc., can solve the problems of high energy consumption, plate breakdown, large operating current of electric desalination equipment, etc., to achieve the effect of strong demulsification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

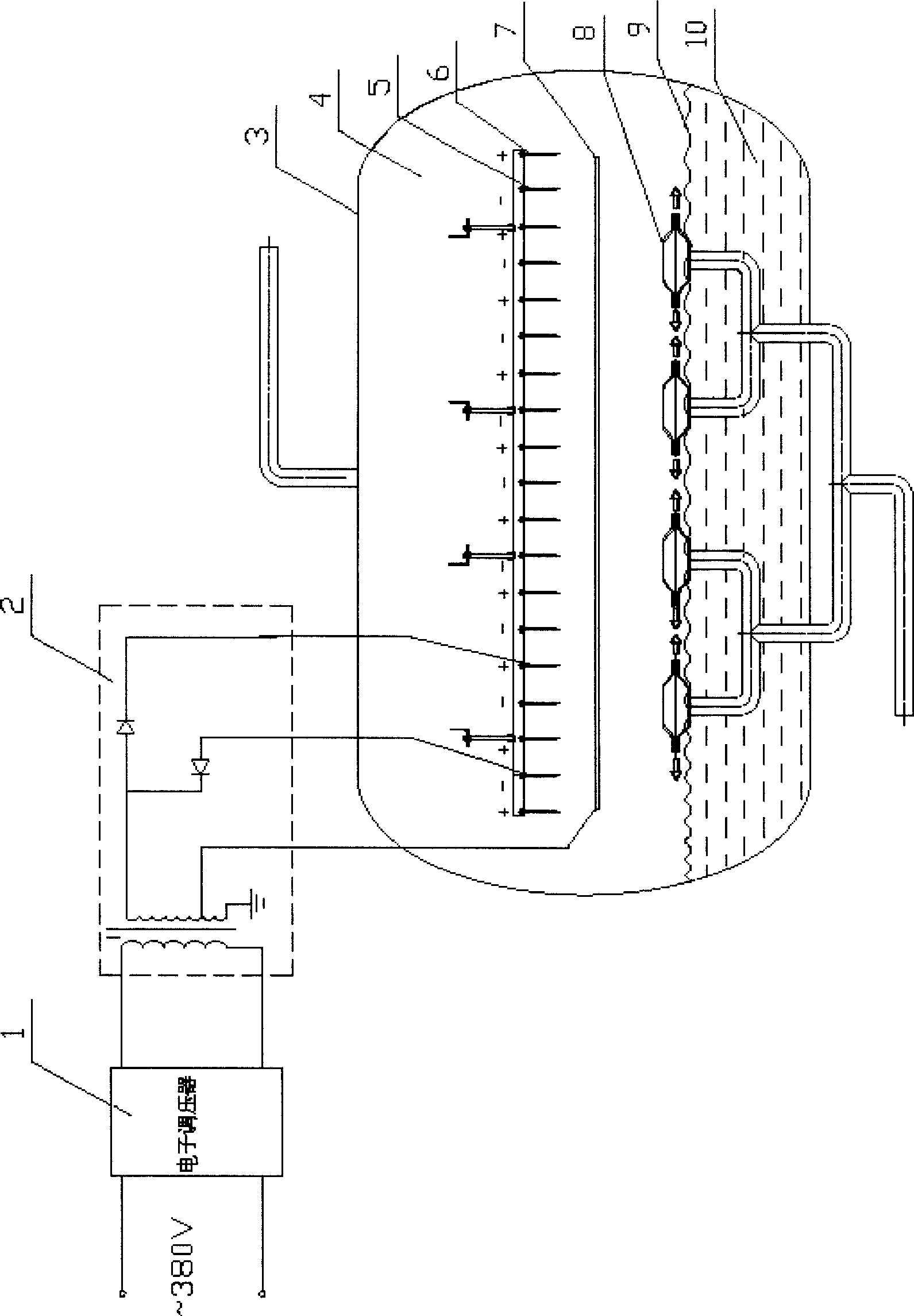

[0026] See attached figure 1 The deep electric desalting technology of heavy and inferior crude oil is a deep electric desalting technology specially designed for the demulsification of stubborn emulsification that is easily formed at the oil-water interface during the processing of heavy and inferior crude oil. During the normal operation of the electric desalination equipment, the upper inner part of the electric desalination tank 3 is the oil phase 4, and the high-voltage electric field will be completely designed in the oil phase 4; the lower part of the electric desalination tank 3 is the water phase 10. Between the oil phase 4 and the water phase 10 is the oil-water interface 9 . During the process of processing heavy and inferior crude oil, a lot of oil-water emulsion will accumulate at the oil-water interface 9 and form an emulsified layer. The emulsified layer contains a large amount of water and has a relatively high conductivity. When the emulsified layer thickens, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com