Equipment and method for melt direct spinning online multicomponent adding production color and functional fibre

A technology of melt direct spinning and functional fibers, which is applied in the directions of adding pigments, fiber treatment, and fiber chemical characteristics to the spinning solution. It is not easy to produce stability and other problems, and achieves the effect of significant consumption reduction, bright and vivid colors, and comprehensive energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

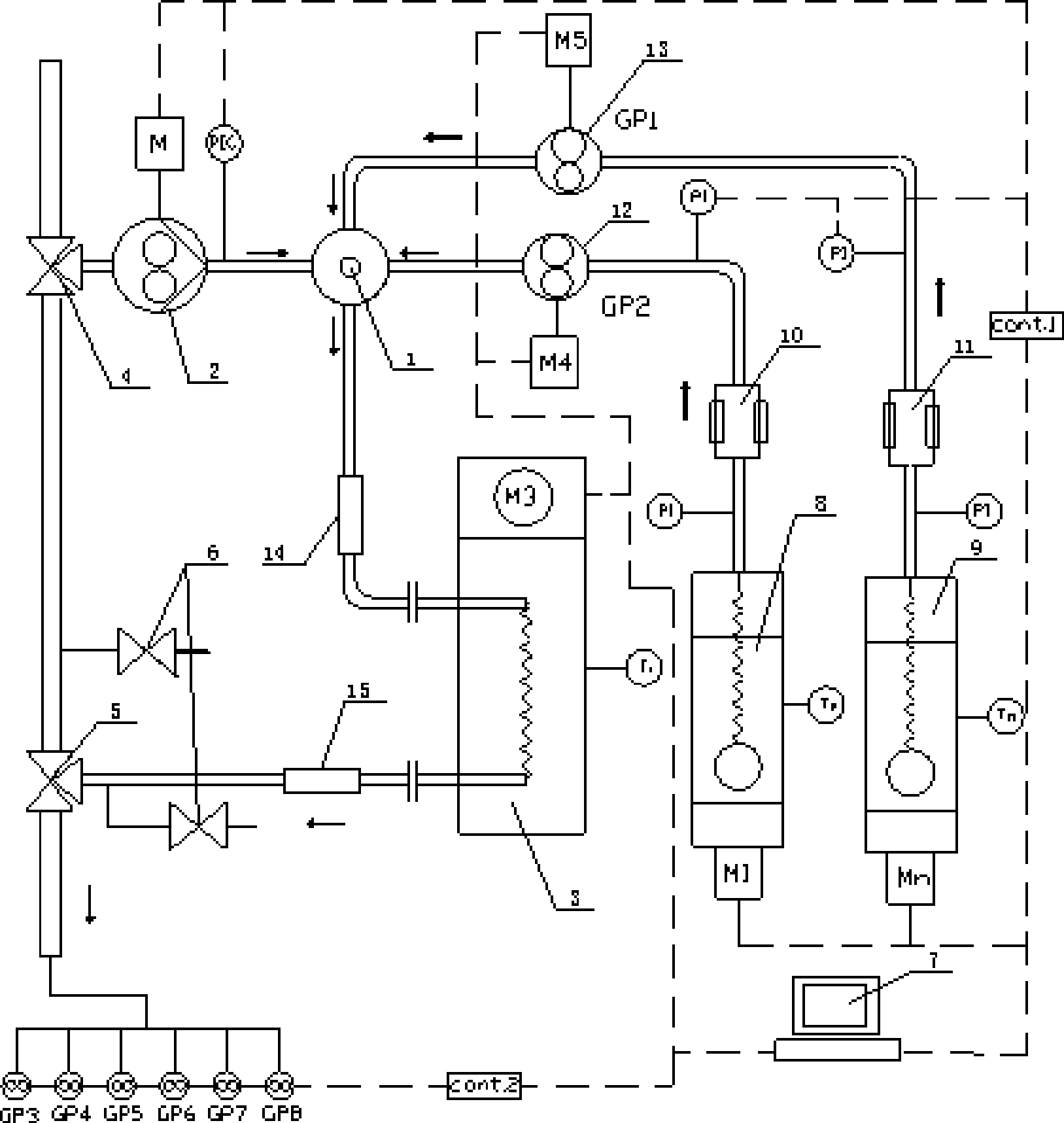

[0032] Embodiment 1: a kind of melt direct spinning on-line multi-component additive production equipment of colored and functional fibers in this example, such as figure 1 , there are a first additive preparation device 8 and a second additive preparation device 9, the first additive preparation device 8 is sequentially connected to the first filter device 10 and the first metering device 12 through pipelines, and the second additive preparation device 9 passes through The pipeline is connected to the second filter device 11 and the second metering device 13 in sequence. In addition, a first three-way valve 4 is provided at the entrance of the main melt, and the first three-way valve 4 is connected with a booster pump 2 through a pipeline. The booster pump 2, the first metering device 12, and the second metering device 13 are all communicated with the multi-element coupler 1, the outlet of the multi-element coupler 1 is connected with a first heat exchanger 14, and the other ...

Embodiment 2

[0039] Example 2: An equipment for producing colored functional fibers by melt direct spinning on-line in this example, the same as Example 1.

[0040] In this example, a method for the production of colored functional fibers by on-line multi-component addition by melt direct spinning, the production unit has 12 spinning positions, such as figure 1 As shown by the arrow, the steps are:

[0041] a. Add the colorant to the first additive preparation device 8, adjust the temperature to 275°C and the pressure to 120Kg / cm 2 Add flame retardant masterbatch to the second additive preparation device 9, adjust the temperature to 270°C and the pressure to 120Kg / cm 2 , and adjust the addition amount through the numerical control device 7;

[0042] b. The flame retardant and additive raw material melts are filtered through the first filter device 10 and the second filter device 11 respectively to filter out abnormal particles and impurities, and then enter the first metering device 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com