Automatic testing, detecting and packaging machine for 49S/SMD crystal

An automatic testing and packaging machine technology, which is used in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, electrical components, etc. It can solve the problems of reverse direction, test detection and automatic packaging. , slow speed and other problems, to achieve the effect of fast speed, high accuracy and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

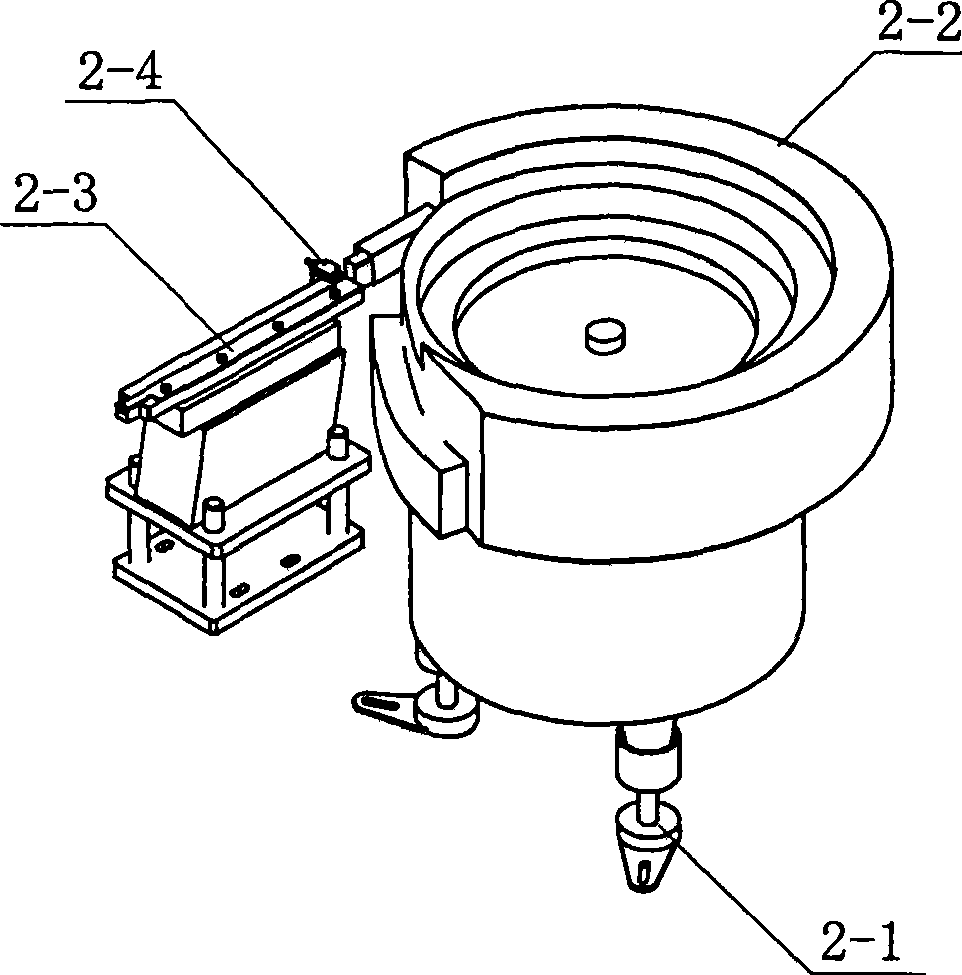

[0024] The 49S / SMD crystal test, detection and packaging machine will be further described in detail below in conjunction with the accompanying drawings. The present invention is applicable to 49S / SMD crystals of high and low materials. The difference in appearance between the two crystals is only 1 mm in height, and the rest are the same, hereinafter referred to as the crystal.

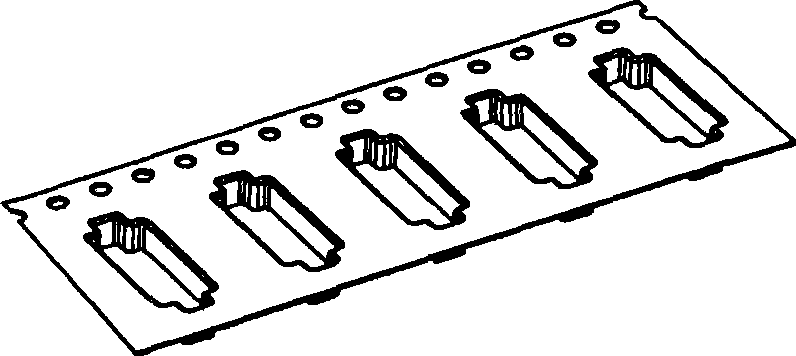

[0025] Such as figure 2 As shown, the carrier tape is a molded tape body made of engineering plastics.

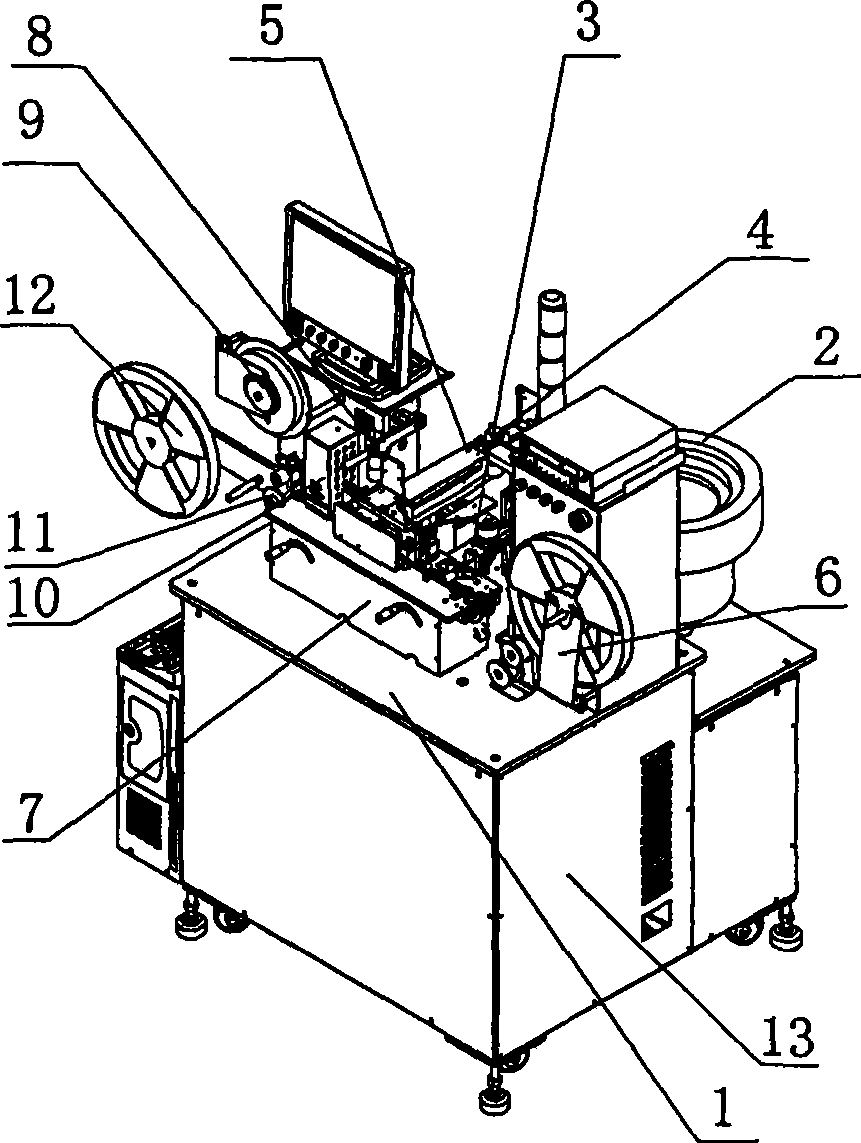

[0026] Such as figure 1 As shown, the present invention is made up of upper, middle and lower parts in appearance: the frame 13 of the lower part and the working platform 1 of the middle part and each device combination of the upper part. The industrial computer installation bracket is designed on the lower left part of the frame 13, and the monitor installation frame is designed on the left side of the upper part; the bracket for placing the measuring instrument is designed on the right part, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com