Cleaning member, delivery member with cleaning function, and method of cleaning substrate processing apparatus

A substrate processing device and a technology for cleaning components, which are applied in the directions of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as difficulty in sufficiently removing submicron-sized fine foreign objects and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

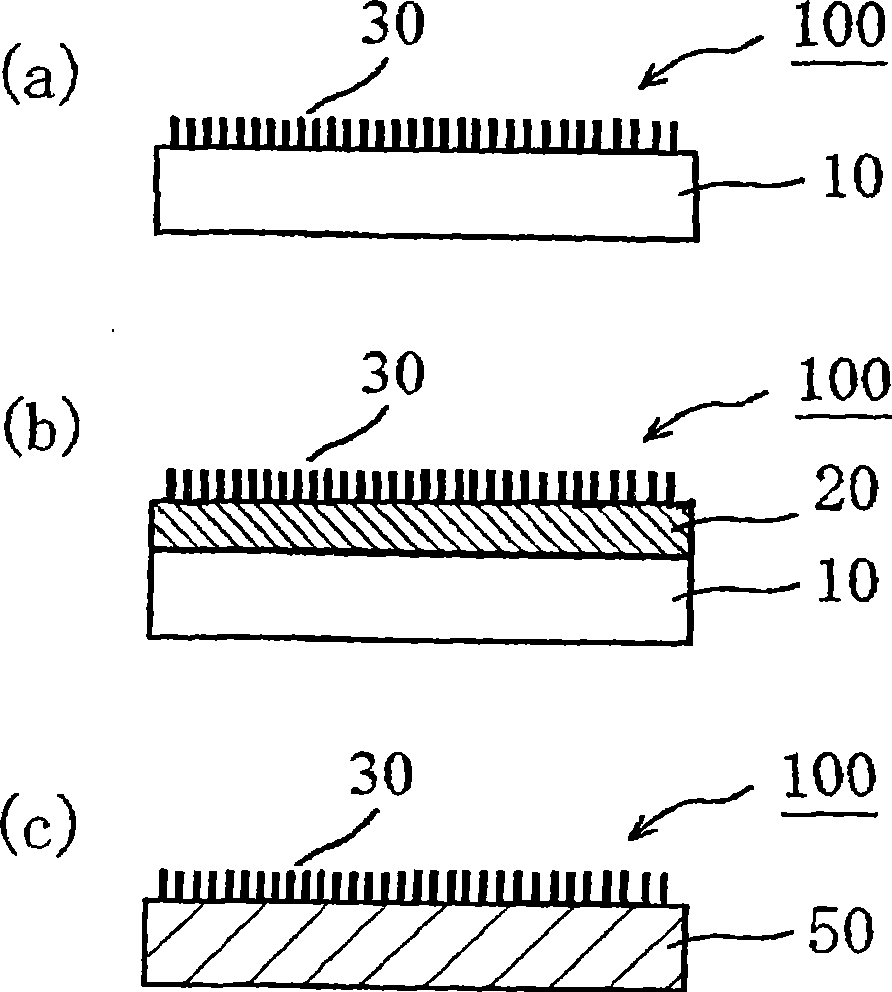

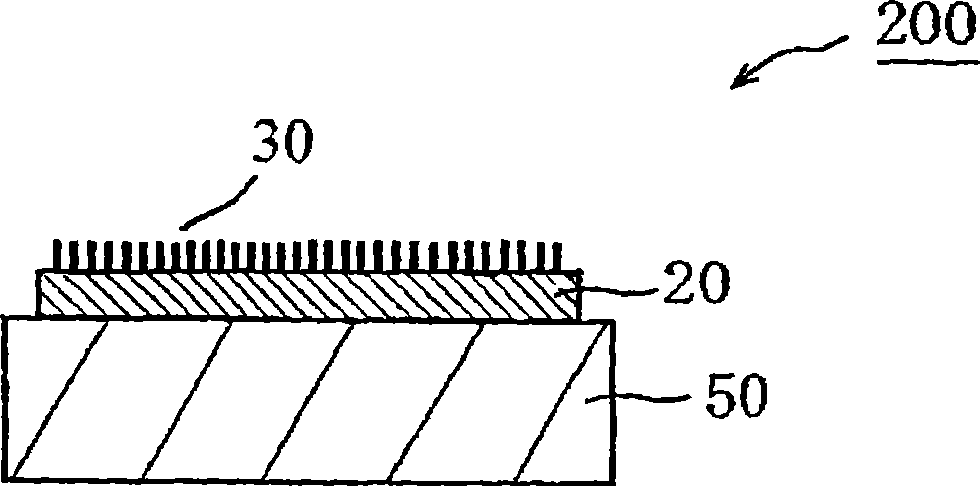

[0090] As catalyst metals, cobalt / molybdenum was dissolved in ethanol and coated on silicon wafers. Oxidation treatment is carried out at 250°C, so that the metal microparticles are uniformly formed on the silicon wafer. The ethanol was then heated to 700°C using an electric furnace to turn it into a vapor, forming multiwalled carbon nanotubes (MWCNTs) vertically oriented on the catalyst metal. In this way, cleaning members (1) to (4) having a layered member provided with a plurality of protrusions of a columnar structure as a carbon-based nanostructure on the surface were produced.

[0091] The multilayered carbon nanotube structures formed in the cleaning members (1) to (4) were observed with a scanning electron microscope (SEM). Table 1 shows the maximum diameter of the obtained multilayer carbon-based nanostructure and the length of the protruding part, and the density of the carbon-based nanostructure on the surface of the layered member. In addition, the dust removal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com