Integral self-cleaning sieve tube of V-shaped joint filter

A filter element and self-cleaning technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of blocking permeability and sand control system, reduced oil well production, low permeability, etc., and achieve excellent sand control performance. , The effect of low percolation resistance and high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

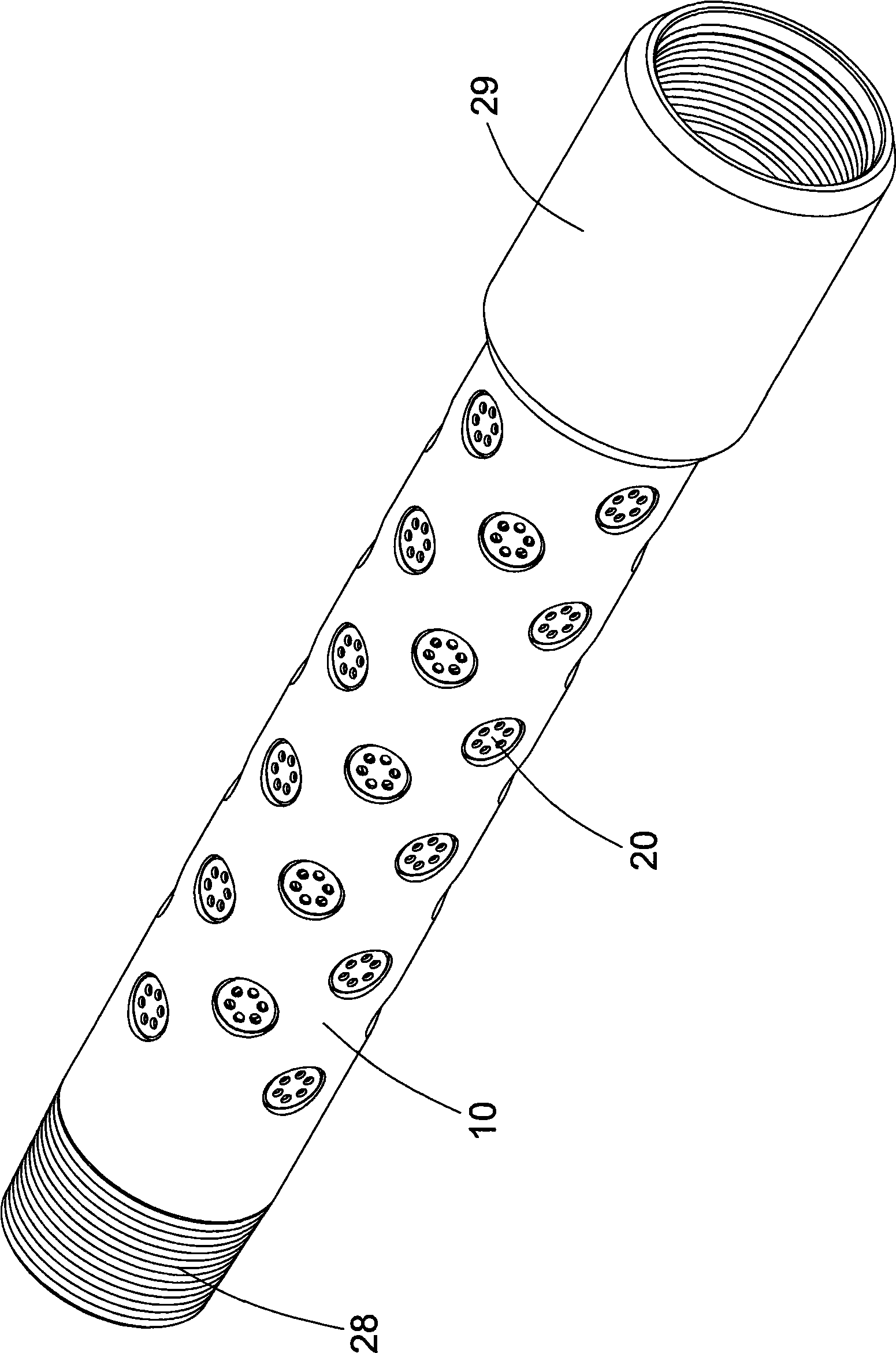

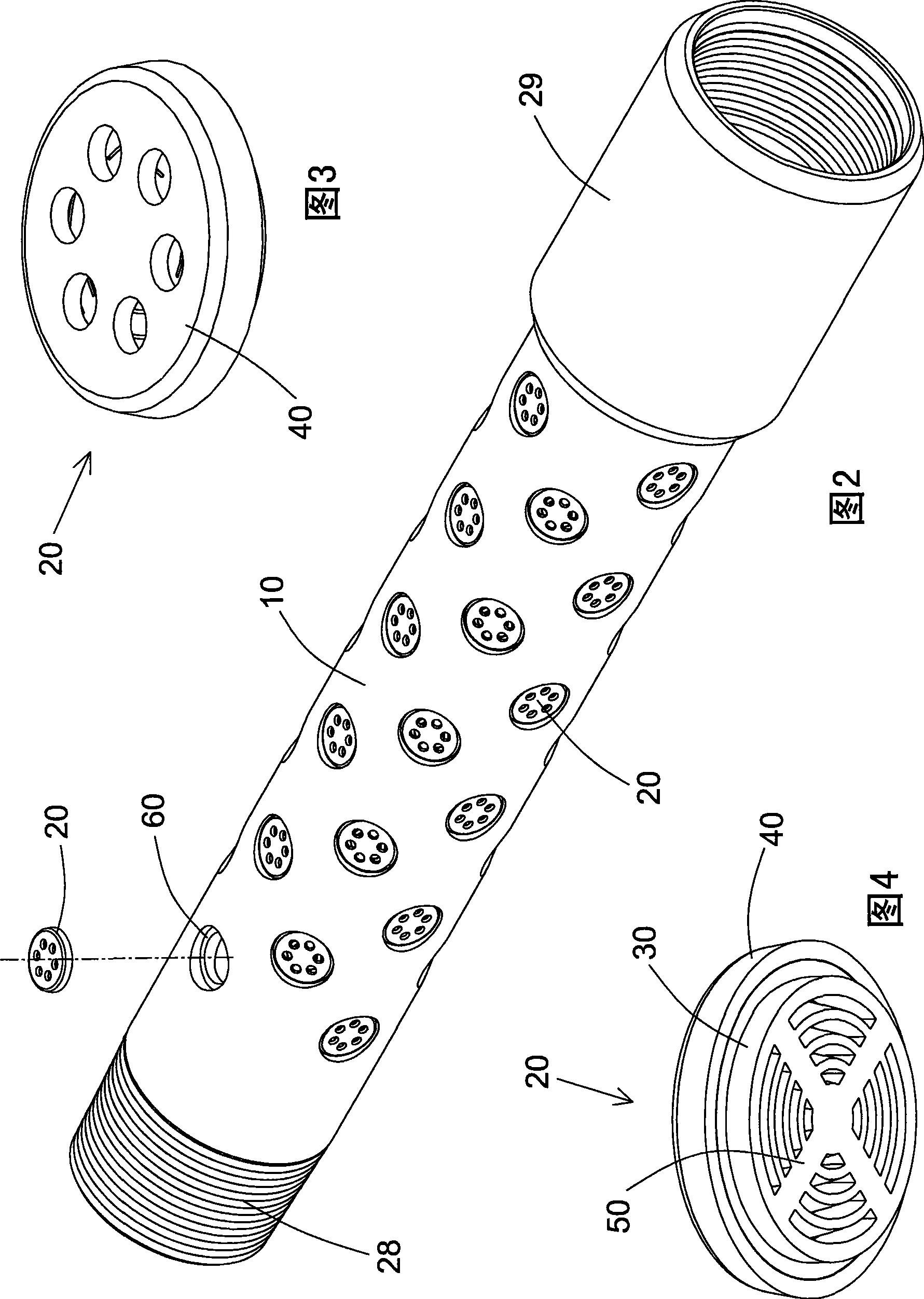

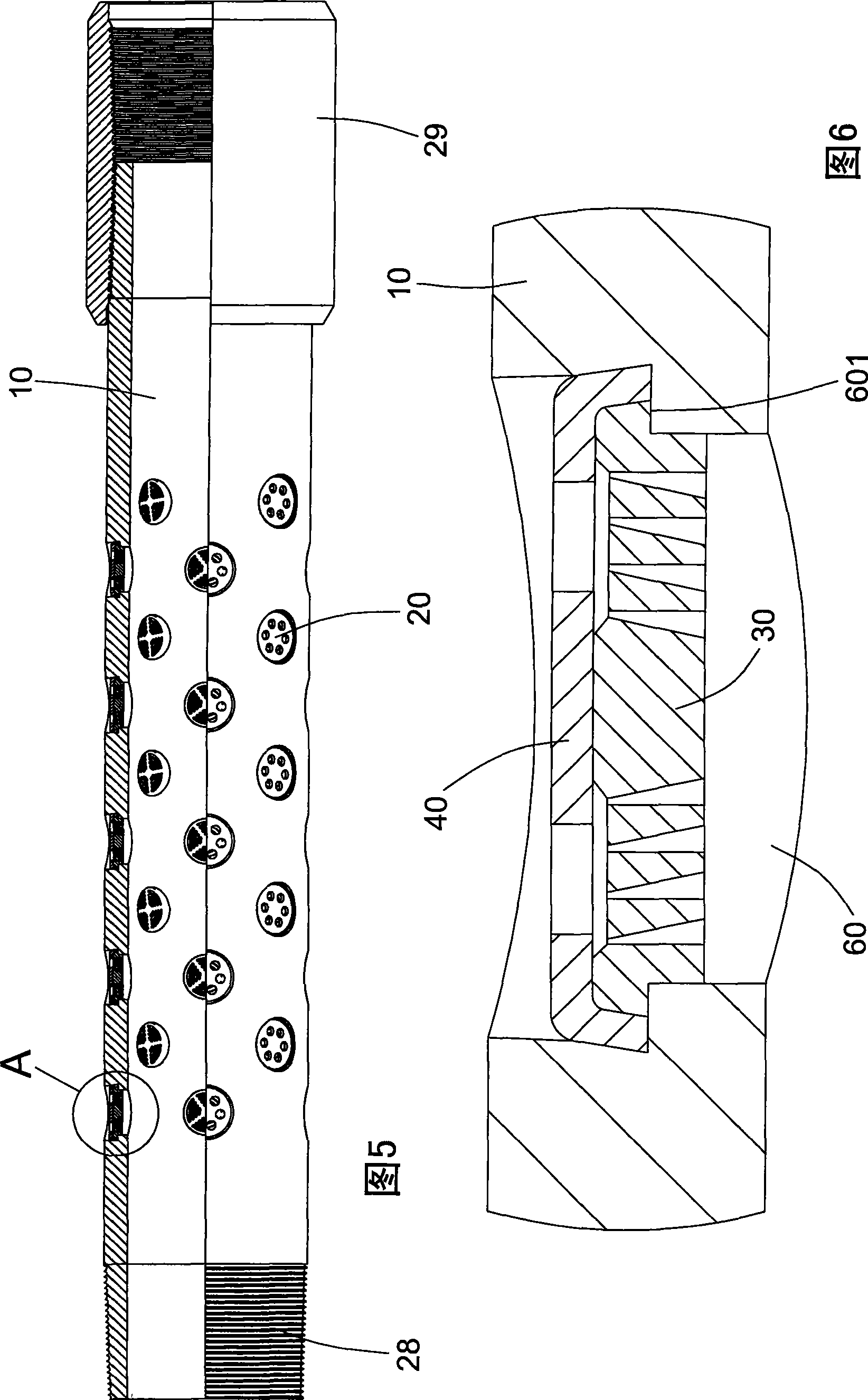

[0067] Please refer to figure 1 , Figure 2, Figure 3, Figure 4 ,Figure 5, Figure 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 The present invention is a self-cleaning screen with integral V-slit filter, which is composed of a base pipe 10 and a filter element 20, the filter element 20 is embedded in the filter hole 60 on the side wall of the base pipe 1, and the filter hole 60 is a belt A through hole with a stepped surface, the filter element 20 is composed of a filter element 30 and a protective cover 40, and the filter element 30 is composed of a central column 1, three filter rings 2, 3, 4, and a fixed ring 5;

[0068] The shape of each filter ring 2, 3, 4 is the same, and the inner diameter size of each filter ring 2, 3, 4 increases in sequence, and the filter rings 2, 3, 4 are nested coaxially together according to the order of the inner diameter size, and the center column 1 is embedded in the filter ring 2 with the smallest inner diameter, the shape of the cente...

Embodiment 2

[0079] Please refer to Figure 11, Figure 12, Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 The present invention is a self-cleaning screen with integral V-slit filter, which is composed of a base pipe 10 and a filter element 20, the filter element 20 is embedded in the filter hole 60 on the side wall of the base pipe 1, and the filter hole 60 is a belt A through hole with a stepped surface, the filter element 20 is composed of a filter element 30 and a protective cover 40, and the filter element 30 is composed of a central column 11, two filter rings 12, 14, and a fixed ring 15;

[0080] The filter rings 12 and 14 have the same shape. The inner diameters of the filter rings 12 and 14 increase in order. The filter rings 12 and 14 are coaxially nested in the order of the inner diameter size. The central column 11 is embedded in the filter ring 12 with the smallest inner diameter. Inside, the shape of the center column 11 corresponds to the shape of the filter ring 1...

Embodiment 3

[0091] Please refer to Figure 18, Figure 19, Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 The present invention is a self-cleaning screen with integral V-slit filter, which is composed of a base pipe 10 and a filter element 20, the filter element 20 is embedded in the filter hole 60 on the side wall of the base pipe 1, and the filter hole 60 is a belt With a stepped through hole, the filter element 20 is composed of a filter element 30 and a protective cover 40. The filter element 30 is composed of a central column 21, five filter rings 22, 23, 24, 25, 26, and a fixed ring 27;

[0092] The shape of each filter ring 22, 23, 24, 25, 26 is the same, and the inner diameter size of each filter ring 22, 23, 24, 25, 26 increases sequentially, and each filter ring 22, 23, 24, 25, 26 is based on the inner diameter size. The order of size is concentrically nested together.

[0093] The center column 21 is embedded in the filter ring 22 with the smallest inner diameter. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com