Ring-shaped vector light beam focusing system

A focusing system and a ring-shaped technology, applied in the field of optics, can solve problems such as limited application range, high requirements for incident beams, and difficulty in changing the shape and size of outgoing beams, achieving high stability and reliability, simple and convenient adjustment methods, and incident Effects with low beam requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

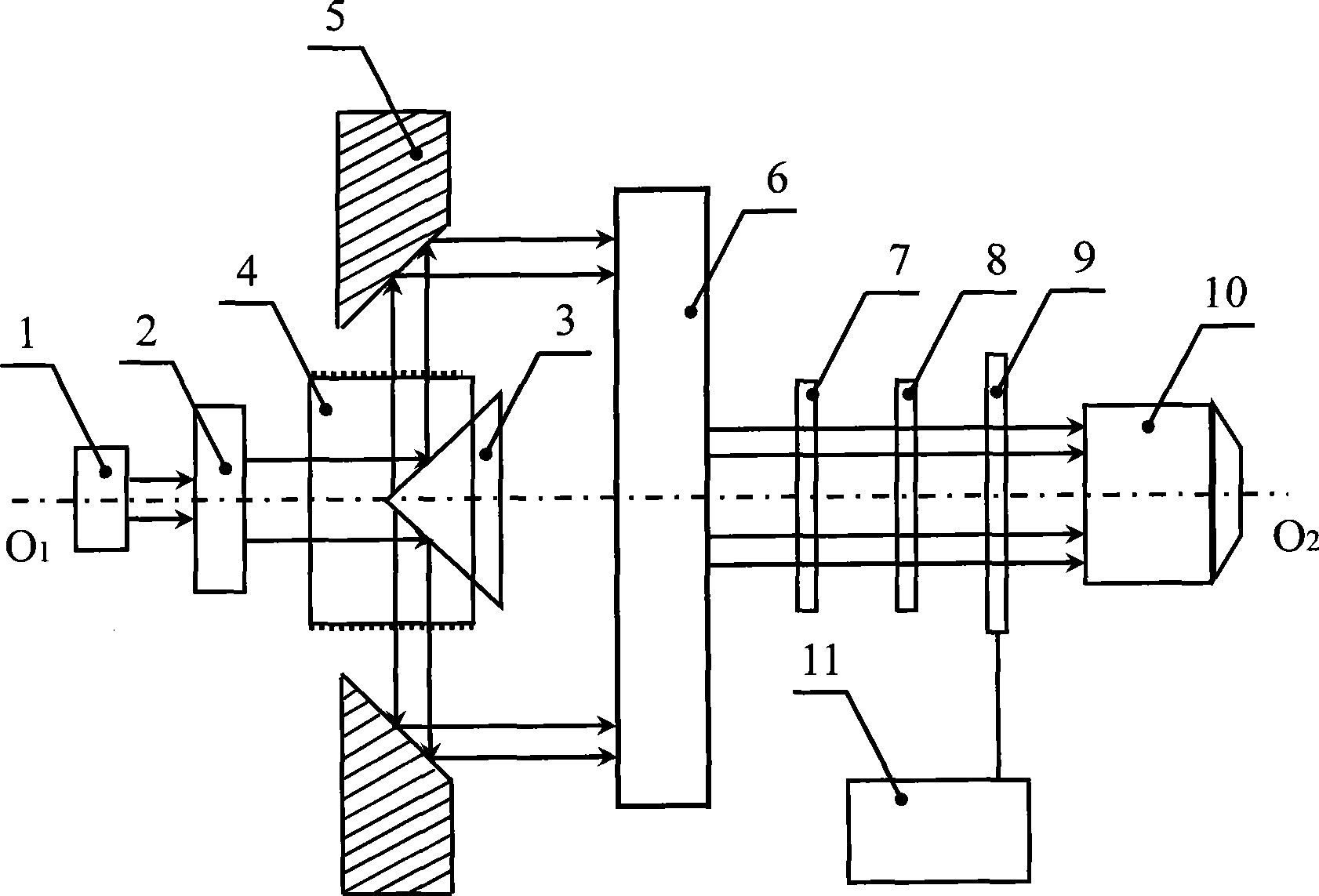

[0023] A circular vector beam focusing system, its structure is as follows figure 1 shown. Incident beam expander shaper 2, external reflection conical mirror 3, cylindrical curved polarizer 4, internal reflection cone mirror 5, exit beam expander shaper 6, entrance half-wave plate 7, exit The half-wave plate 8 , the spatial light modulator 9 and the objective lens 10 are sequentially arranged on the optical path of the light beam emitted by the light source 1 with the symmetrical optical axis; the spatial light modulator controller 11 is connected with the spatial light modulator 9 .

[0024] The reflective cone of the external reflective conical reflector 3 is parallel to the reflective conical of the internal reflective conical reflector 5, and the reflective cone of the external reflective conical reflector 3 and the internal reflective c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com