Improved transparent polypropylene composition

A polypropylene composition and composition technology, applied in the direction of synthetic resin layered products, layered products, rubber layered products, etc., can solve problems such as low impact strength, and achieve the effect of high transparency and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

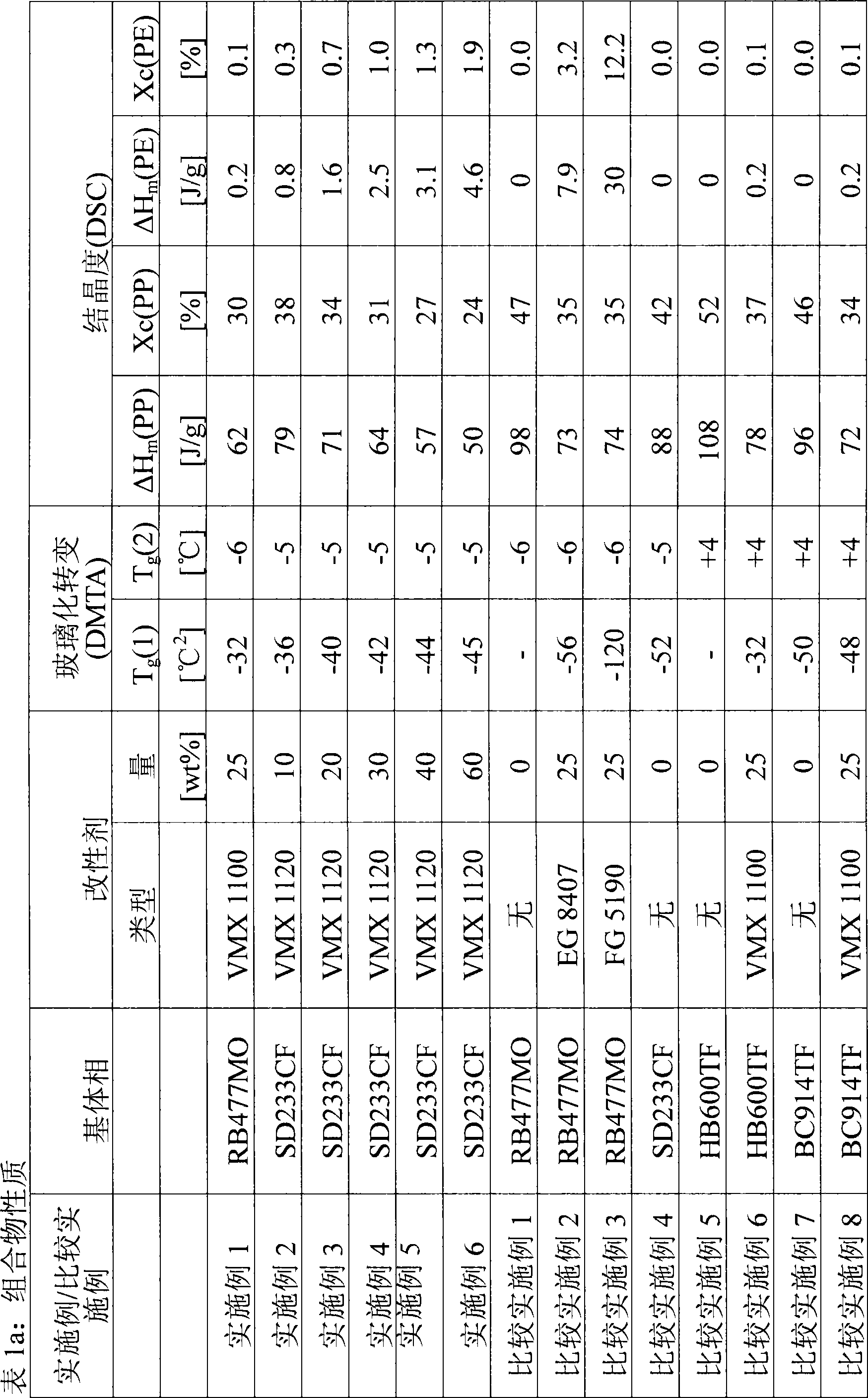

[0045] Preparation of Random Copolymer (A)

[0046] The propylene random copolymer (A) can be prepared by one or more steps of polymerizing propylene and ethylene and / or α-olefins (such as bulk polymerization, gas phase polymerization, slurry polymerization, solution polymerization or combinations thereof) using conventional catalysts . Random copolymers can be prepared in a loop reactor or in a combination of a loop reactor and a gas phase reactor. These processes will be apparent to those skilled in the art.

[0047] A suitable catalyst for the polymerization of the propylene random copolymer is any stereospecific catalyst for the polymerization of propylene which is capable of polymerizing and copolymerizing propylene with the comonomer at a temperature of 40-110°C and a pressure of 10-100 bar. Ziegler-Natta catalysts and metallocene catalysts are suitable catalysts.

[0048] Those skilled in the art recognize the various possibilities for preparing propylene copolymers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com