Double-magazine double main-shaft machine tool for processing two-end holes of crankshaft

A dual-spindle and hole processing technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of narrow processing range, expensive power head, low power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

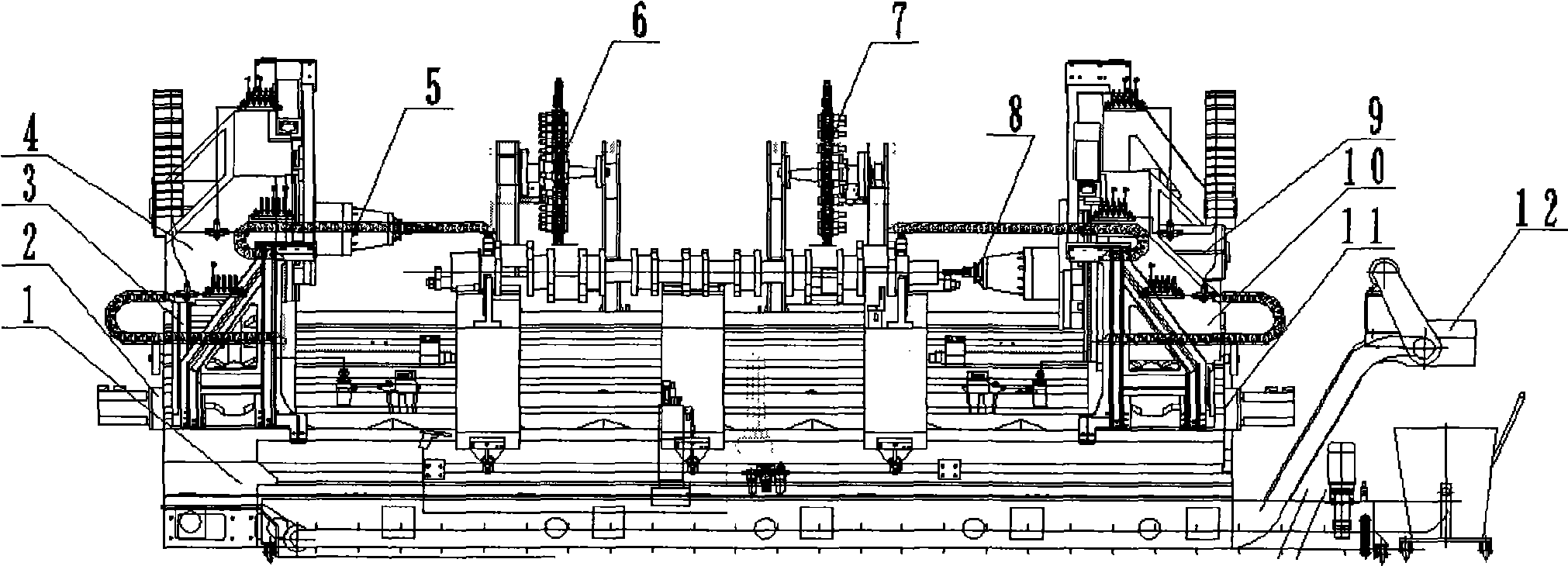

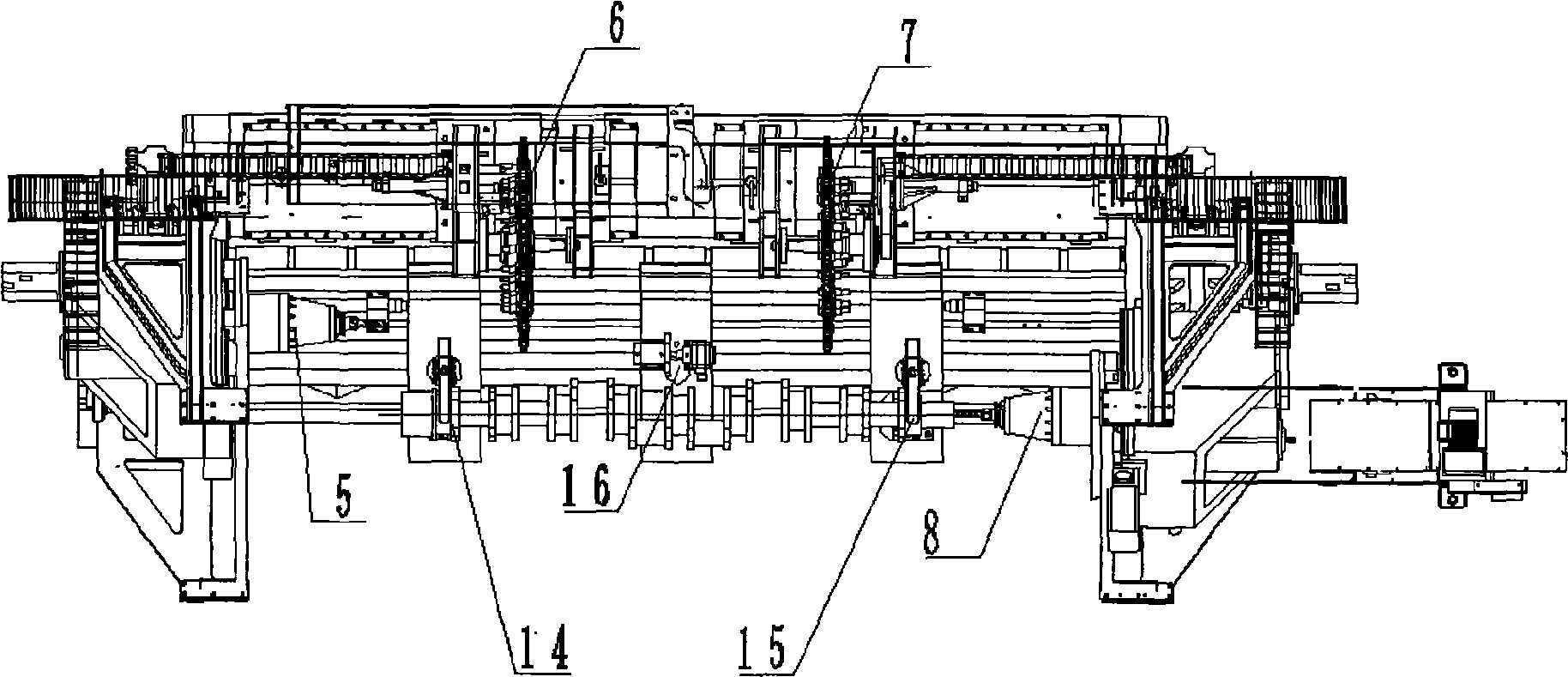

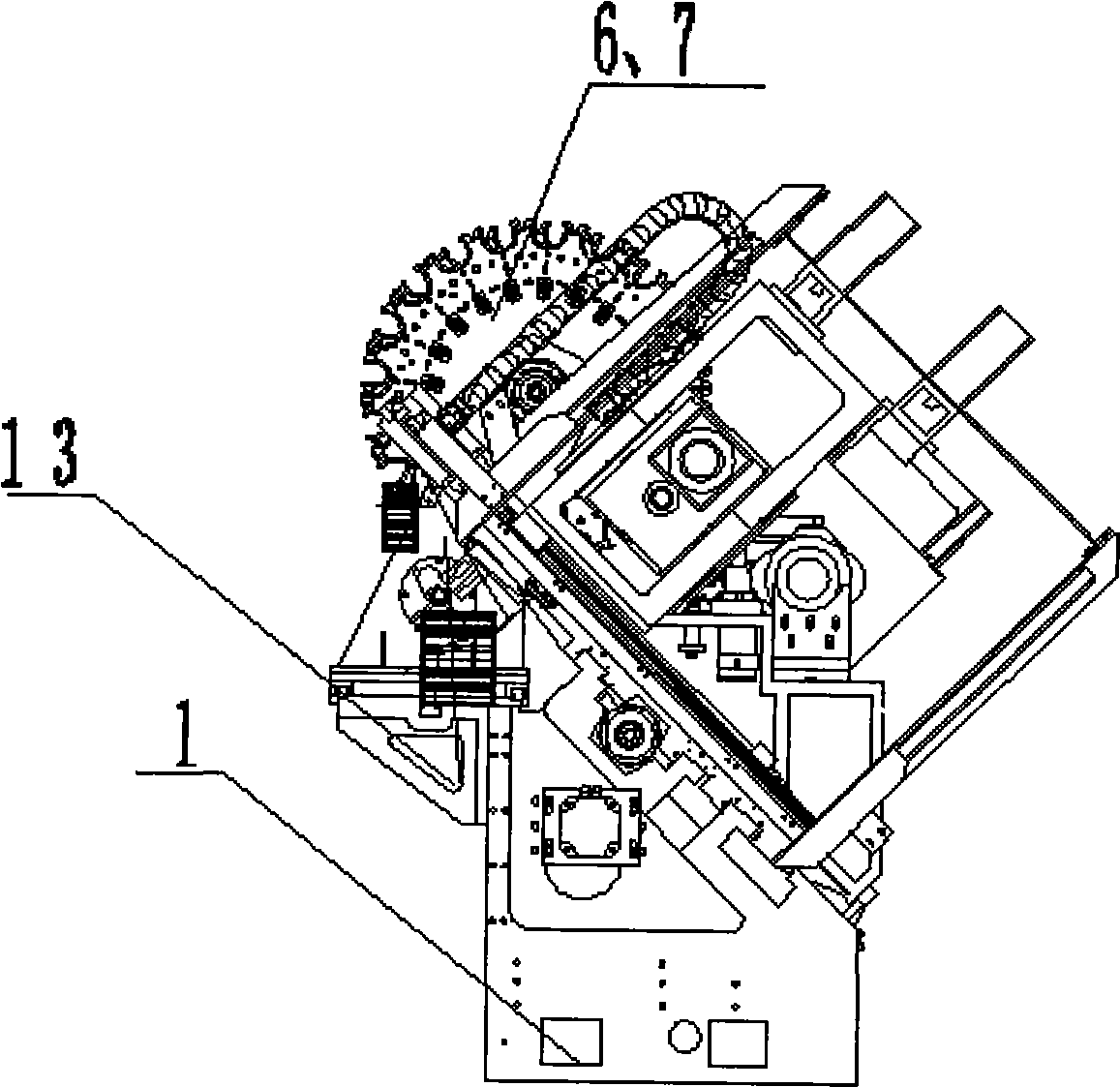

[0012] Such as Figure 1-Figure 6 As shown, the dual-spindle and dual-tool magazine special CNC machine tool with holes at both ends of the crankshaft includes an integral casting 45° inclined bed (1) for easy chip removal, a left Z-axis screw component (2), and a left X-axis saddle component ( 3), left Y-axis component (4), left spindle (5), left tool magazine (6), right tool magazine (7), right spindle (8), right Y-axis component (9), right X-axis sliding saddle Piece (10), right Z-axis screw component (11), chip cooling component (12), tool magazine carriage (13), left clamp (14), right clamp (15), bracket (16). The left main shaft (5) is installed on the left Y-axis component (4), the left Y-axis component (4) is installed on the left X-axis saddle component (3), and the left X-axis saddle component (3) is installed on the left Z-axis On the screw component (2), these four components are assembled together to form the left three-coordinate unit. In the same way, the right main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com