Process for producing active carbon

A technology of activated carbon and carbonization, which is applied in the field of activated carbon preparation, can solve problems such as waste of resources and environmental problems, achieve the effects of low content of harmful elements, good adsorption performance, and solve the problems of waste of resources and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

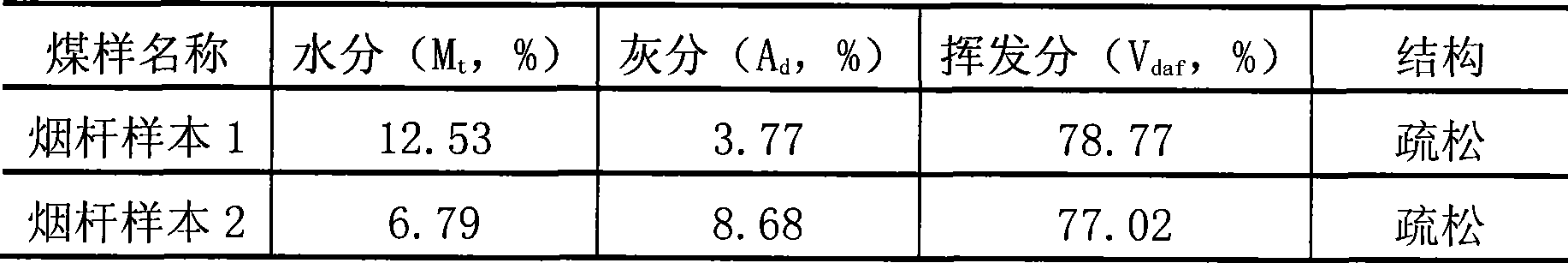

[0030] Embodiment 1, utilize tobacco rod to produce activated carbon for sewage treatment

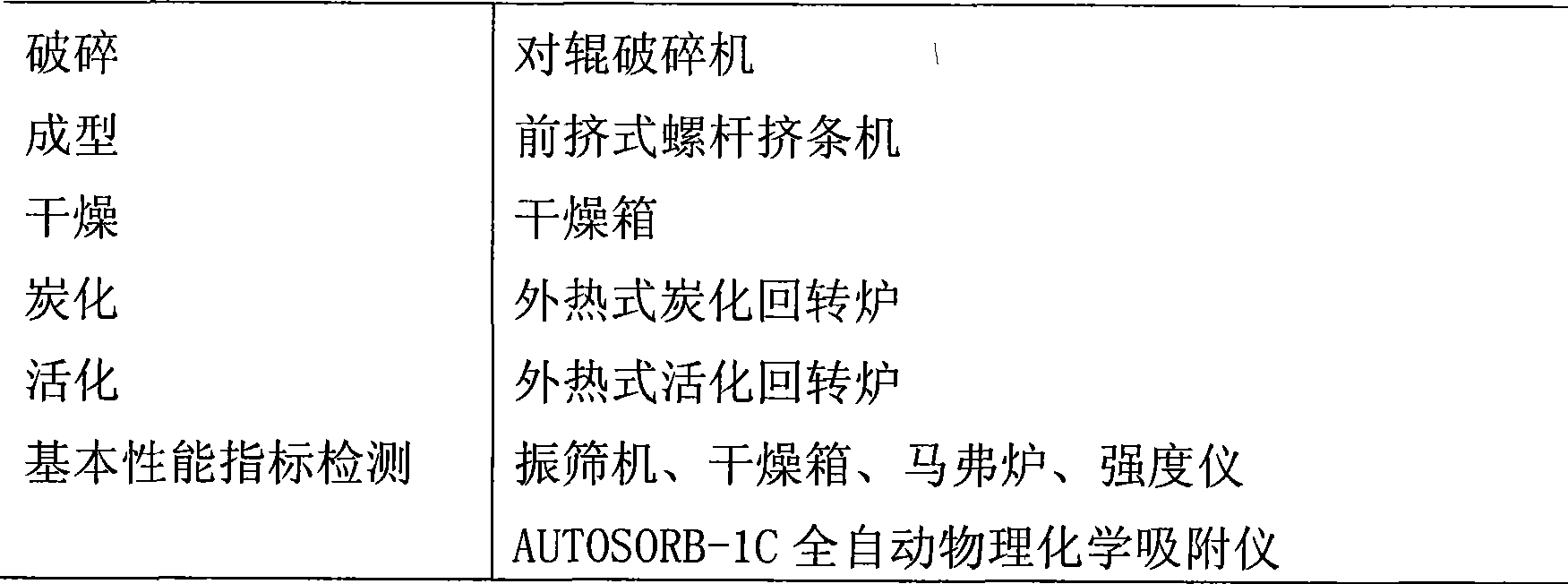

[0031] 1. Crush 1000g of tobacco rod sample 1 to a particle size of 4-6 mm.

[0032] 2. Drying the crushed tobacco rod particles.

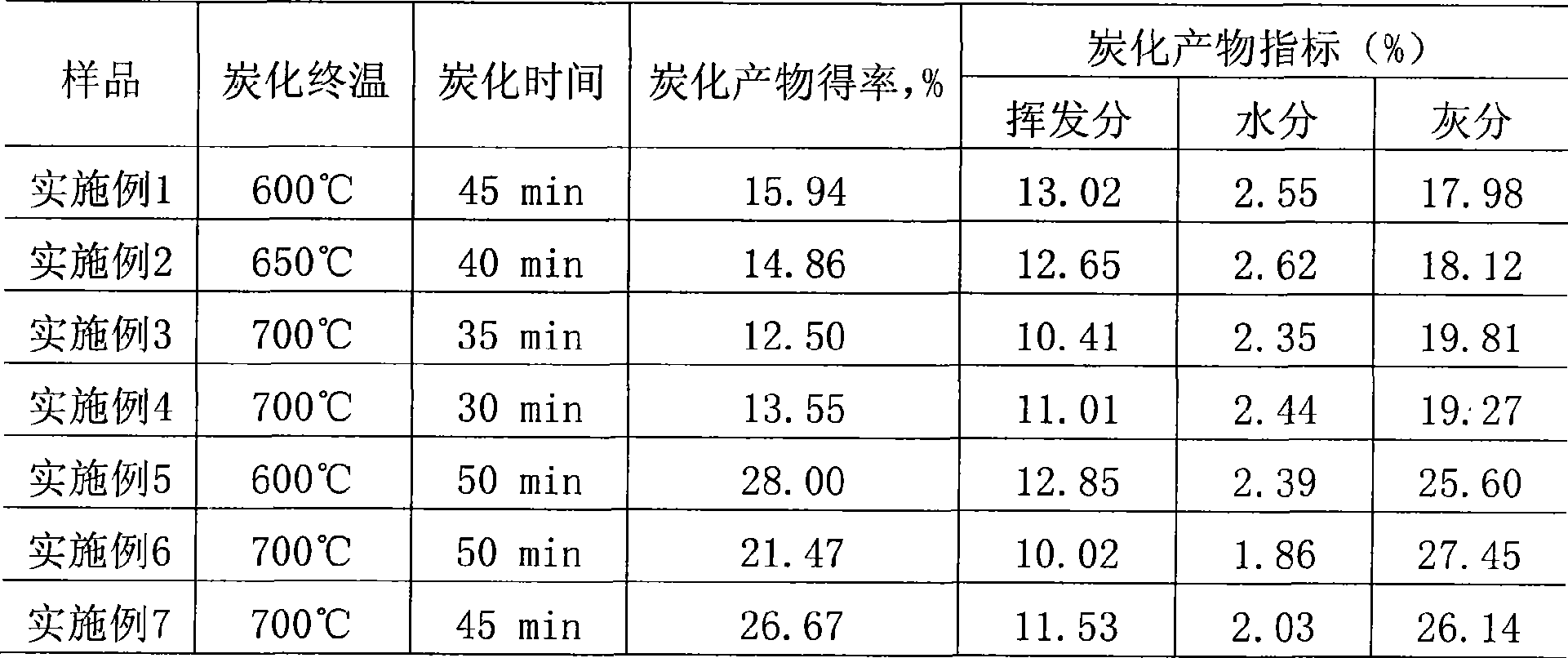

[0033] 3. Carbonize the dried tobacco rod particles, the final temperature of carbonization is 600° C., and the carbonization time is 45 minutes to obtain a carbonized product. Calculate the carbonization yield (carbonization yield = carbonization product mass / tobacco rod sample mass × 100%) and the performance index of the carbonization product (standard number: GB / T212-2001), and the results are shown in Table 3.

[0034] 4. Activate the carbonized product, the activation temperature is 800°C, and the activation time is 5 minutes to obtain activated carbon. Calculate the activated carbon yield (activated carbon yield=activated carbon quality / carbonized product quality×100%") and the performance index of activated carbon. The results are shown in Table 4 a...

Embodiment 2

[0035] Embodiment 2, utilize tobacco rod to produce activated carbon for sewage treatment

[0036] 1. Same as step 1 in Example 1.

[0037] 2. Same as step 2 of embodiment 1.

[0038] 3. Carbonize the dried tobacco rod particles, the final temperature of carbonization is 650° C., and the carbonization time is 40 minutes to obtain a carbonized product. Calculate the carbonization yield and the performance index of the carbonization product, and the results are shown in Table 3.

[0039] 4. Activate the carbonized product, the activation temperature is 800°C, and the activation time is 8 minutes to obtain activated carbon. Calculate the activated carbon yield and the performance index of activated carbon. The results are shown in Table 4 and Table 5.

Embodiment 3

[0040] Embodiment 3, utilize tobacco rod to produce activated carbon for sewage treatment

[0041] 1. Same as step 1 in Example 1.

[0042] 2. Same as step 2 of embodiment 1.

[0043] 3. Carbonize the dried tobacco rod particles, the final temperature of carbonization is 700° C., and the carbonization time is 35 minutes to obtain a carbonized product. Calculate the carbonization yield and the performance index of the carbonization product, and the results are shown in Table 3.

[0044] 4. Activate the carbonized product, the activation temperature is 800°C, and the activation time is 10 minutes to obtain activated carbon. Calculate the activated carbon yield and the performance index of activated carbon. The results are shown in Table 4 and Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com