Applied technology for realizing circular economy industrial chain in benzoic acid purification production process

An application technology and production process technology, which is applied in the field of application technology to realize the industrial chain of circular economy in the production process of refined benzoic acid, to achieve the effects of saving funds, saving production funds, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

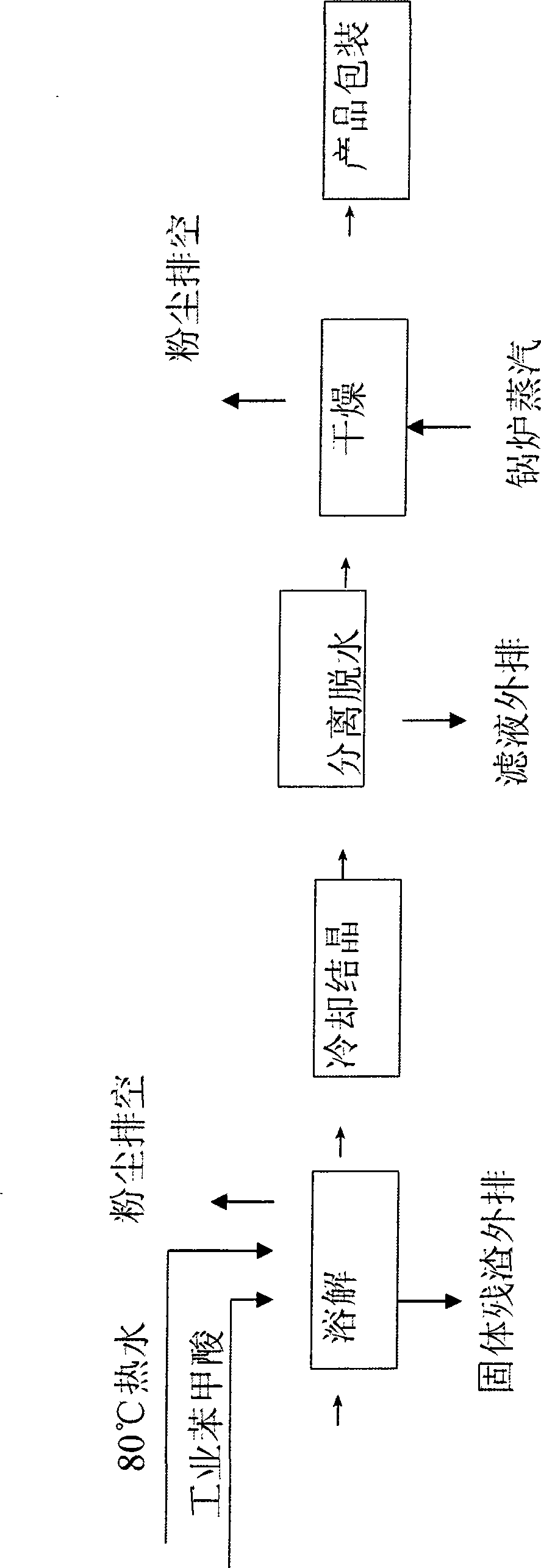

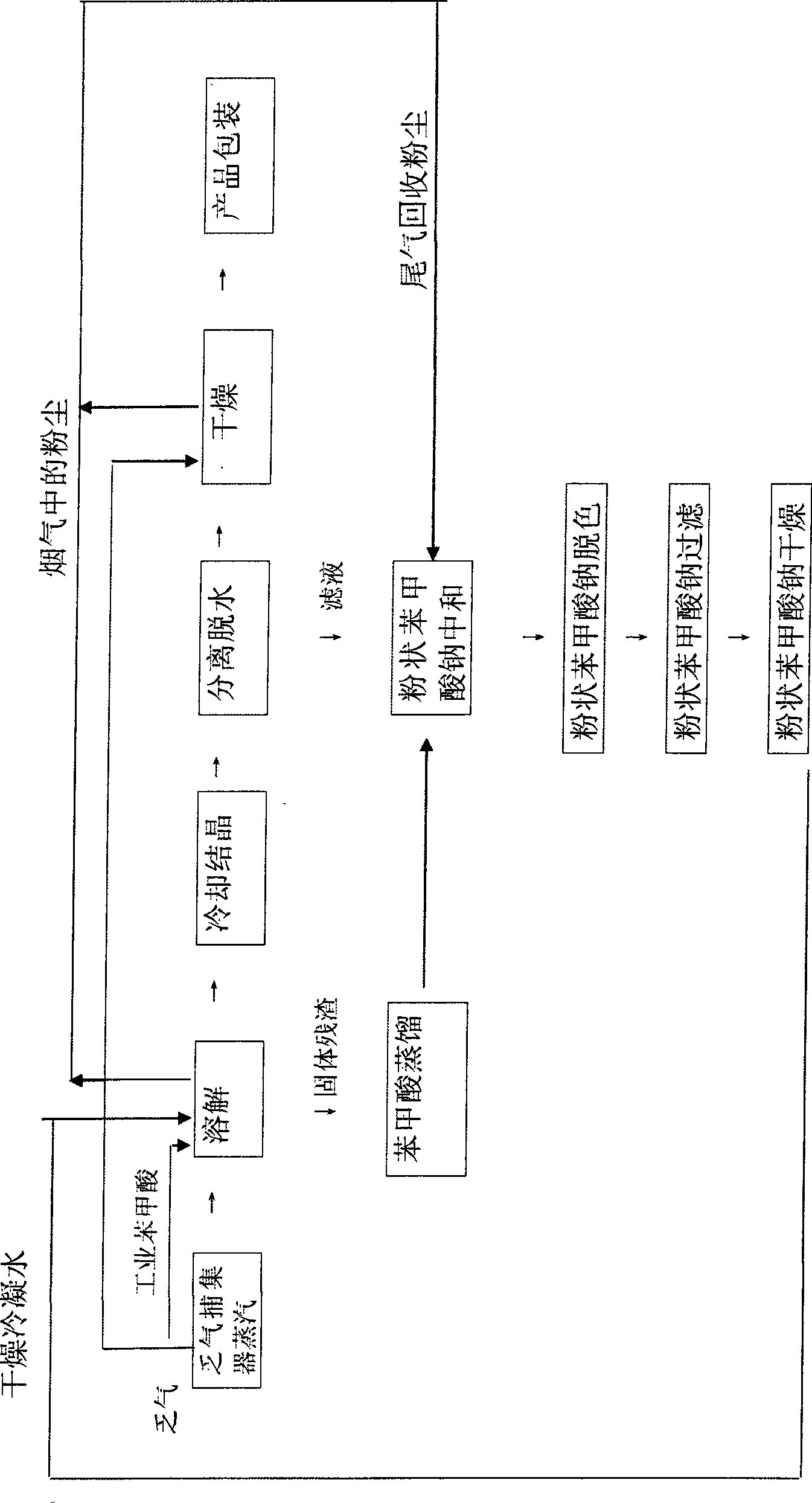

Method used

Image

Examples

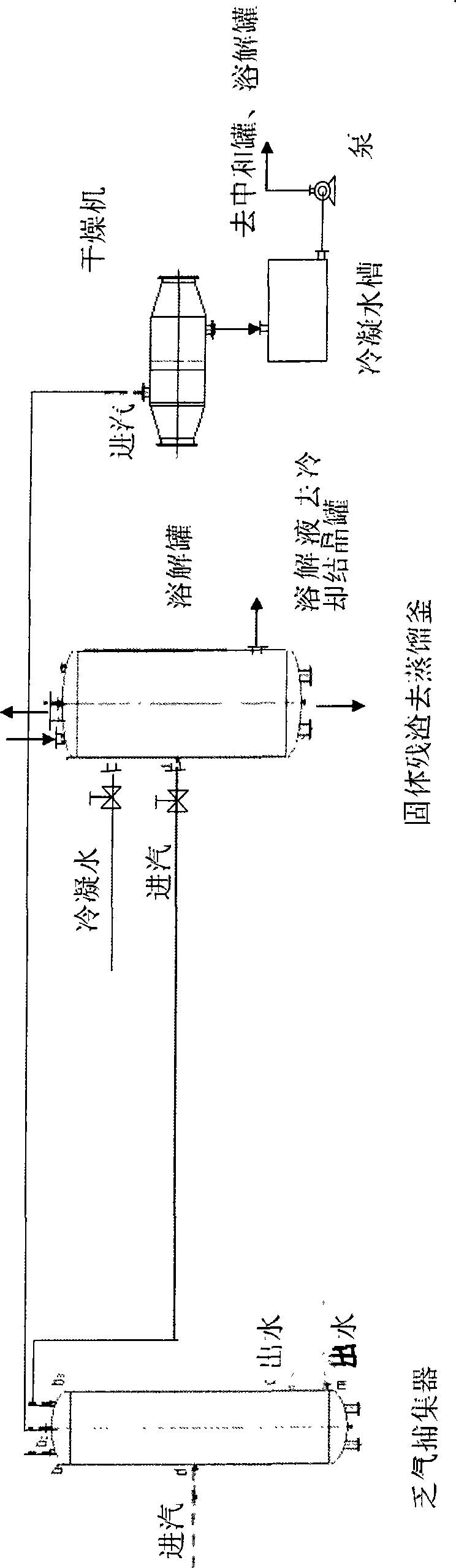

Embodiment 1

[0043] Such as image 3 As shown, the exhaust steam comprehensive utilization process is composed of exhaust steam trap-dissolving tank-dryer. In the dissolution process and drying process of the refined benzoic acid production process, the steam required for heating is collected by the exhaust steam Provided by the steam boiler instead of the saturated steam provided by the steam boiler. Add industrial benzoic acid into the dissolving tank, open the water inlet valve of the dissolving tank, and add the condensed water from the powdered sodium benzoate dryer. Close the water inlet valve after the water level reaches the scale required by the production operation. Open the steam inlet valve of the dissolution tank, feed the steam of the exhaust steam trap, and heat the industrial benzoic acid solution. When the temperature in the dissolution tank reaches the requirements of the production process, stop heating and close the steam valve. After the solution settled in the tank...

Embodiment 2

[0046] Such as Figure 7 As shown, the comprehensive utilization process of condensed water is composed of powdery sodium benzoate dryer-dissolving tank. The solvent for dissolving industrial benzoic acid in the dissolving tank is the condensed water from the powdered sodium benzoate dryer.

[0047] During the production process, the condensed water from the powdered sodium benzoate dryer enters the dissolution tank through the pipeline. Since the industrial benzoic acid is dissolved by using the steam condensed water of the powdered sodium benzoate dryer, the dissolution tank can save 5m water for one dissolution process 3 . The dissolving tank can dissolve 25 times a day (24 hours), saving a total of 125m of water 3 (5m 3 / tank × 25 tanks = 125m 3 / day), one month water saving (125m 3 / day × 30 days = 3750m 3 / month), the annual water saving can be 41250m 3 (3750m 3 / month×November=41250m 3 ).

Embodiment 3

[0049] Such as Figure 4 As shown, the solid residue recycling process is composed of a dissolution tank-benzoic acid distillation tank-neutralization tank. The solid residue after static precipitation of the solution in the dissolution tank, that is, the undissolved substance, enters the benzoic acid distillation process through the discharge valve at the bottom of the dissolution tank, and enters the powdery sodium benzoate production after being purified into benzoic acid by the benzoic acid distillation kettle The neutralization tank in the system is used as the raw material for the production of powdery sodium benzoate products.

[0050] During the dissolution process, the solid residue that settles down after each dissolution process in the dissolution tank is 15kg of undissolved material, and the solid residue that settles down in one day is 375Kg (15Kg / tank×25 tanks=375Kg / day), and it settles down in one month The solid residue is (375Kg / day×30 days=11250Kg / month), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com