High-strength Q420C level steel tower corner iron and production process

A technology of iron tower angle steel and production process, which is applied in the field of iron and steel smelting. It can solve the problems of many inclusions and the 0°C impact energy of angle steel cannot meet the standard requirements, and achieve the effects of solving nodules, reducing the number of pearlite, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

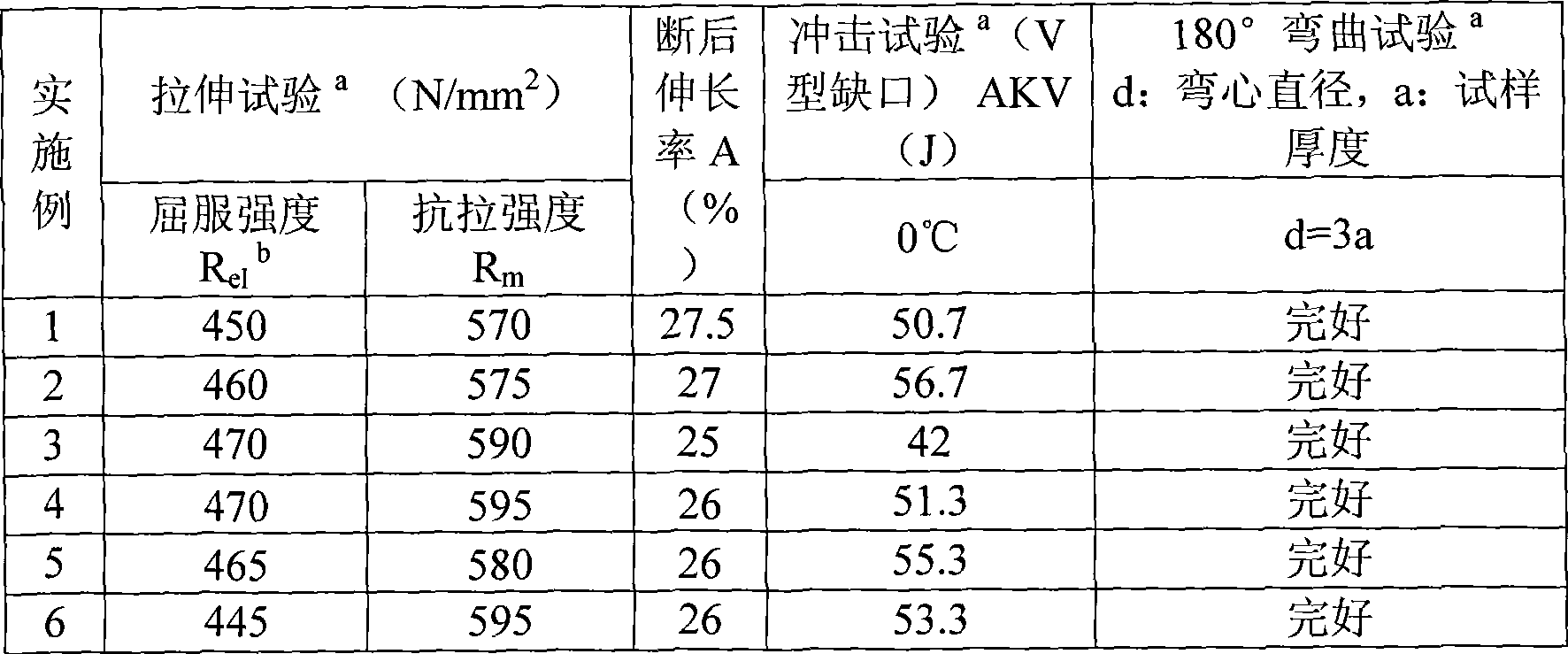

Examples

Embodiment Construction

[0017] Main feature of the present invention is embodied in following three aspects:

[0018] 1. In order to improve the impact performance and ensure the weldability, the composition ratio breaks through the standards of "GB / T1591-1994 Low Alloy High Strength Structural Steel" and "YBT4163-2007 Hot Rolled Angle Steel for Iron Tower", and gives the carbon equivalent Require.

[0019] 2. The steelmaking process adopts VN alloy with vanadium, replaces the conventional vanadium microalloying with vanadium nitrogen microalloying, and adds Ti to VN steel. Generally speaking, N is a harmful element in steel. In the metallurgical production process of iron and steel materials, it is difficult to remove it unless a very high-cost refining method is used. For ordinary steel structural materials, the accumulation of nitrogen elements in structural defects such as grain boundaries will cause aging phenomena, which will increase the strength of the steel and decrease the toughness. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com