Steel reinforced concrete frame-off-centering steel shotcrete combined structure system

A technology of reinforced concrete and frame structure, which is applied in building components, building structure, earthquake-proof and other directions, and can solve the problems of complex structure, weakening the seismic performance of joints, and large reduction in stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following embodiments will further illustrate the present invention in conjunction with the drawings.

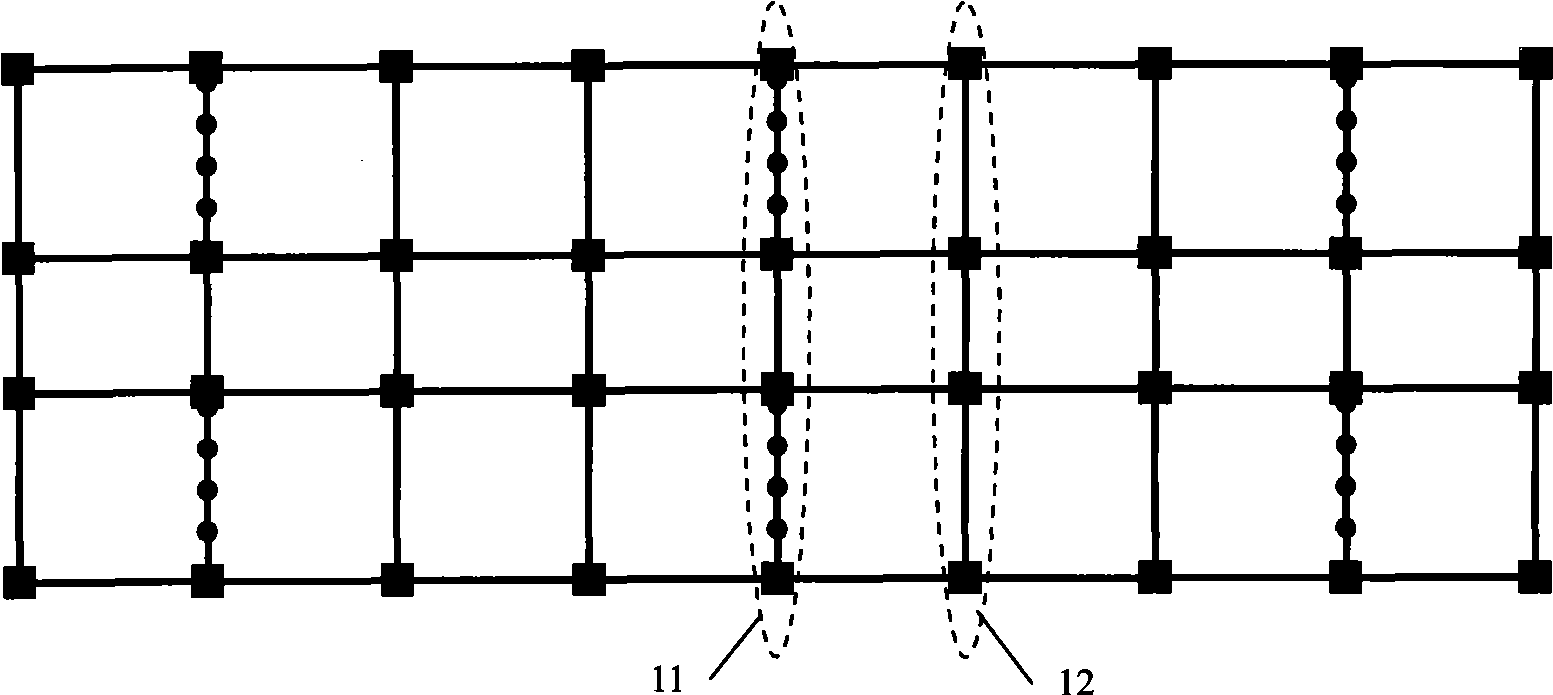

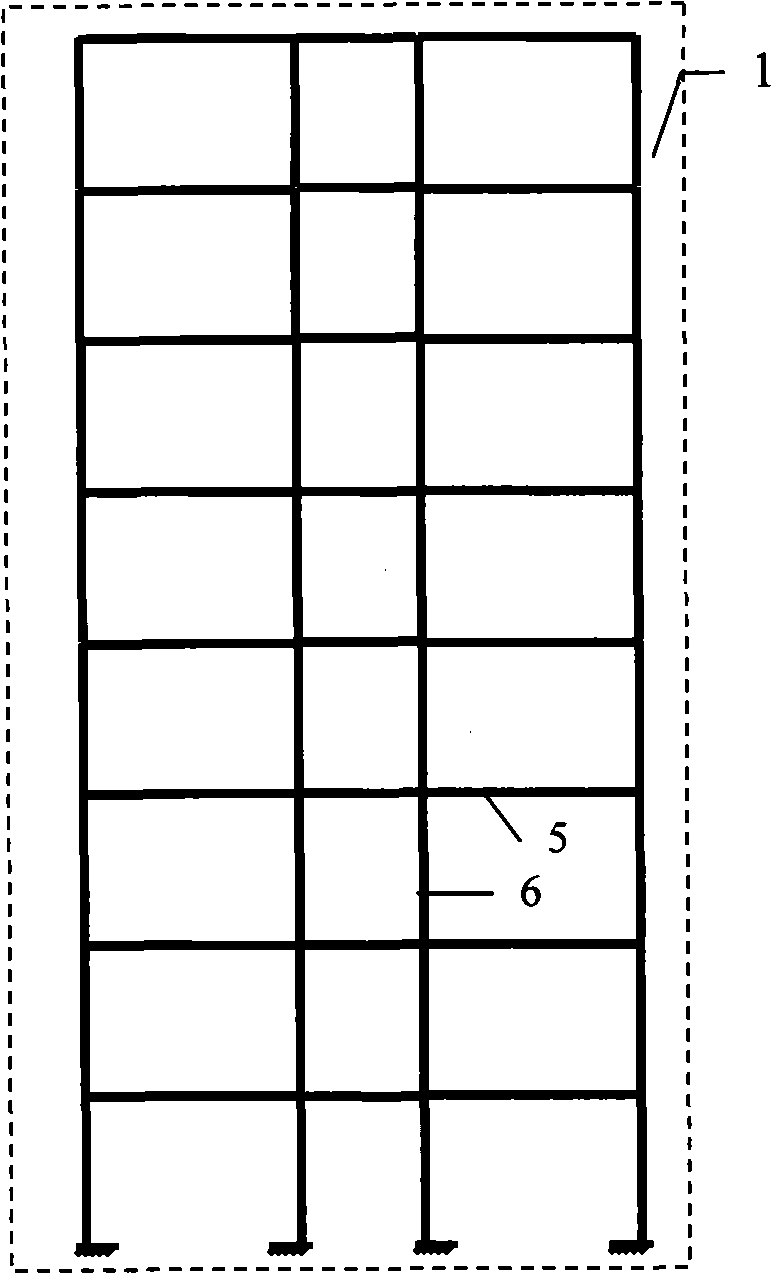

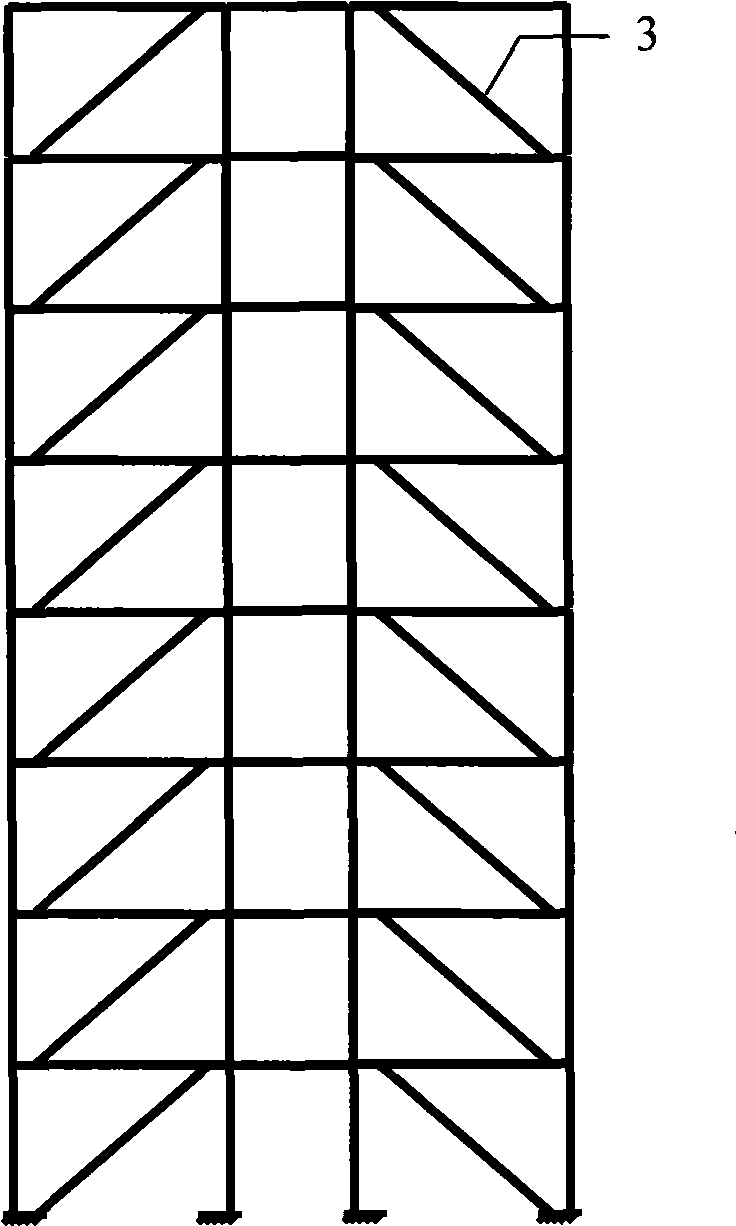

[0057] The invention is a new type of building structure system, which provides an engineering construction method based on reinforced concrete frame for building structure design, which is mainly implemented through the design of building engineering. Facing the architectural plan, when the reinforced concrete frame structure cannot meet the requirements of the lateral rigidity or bearing capacity of the structure, a certain number of eccentric steel supports are arranged on the plane and vertical of the building to increase the lateral rigidity or bearing capacity of the structure. The combined structural system of eccentric steel support and concrete frame can meet the requirements of structural lateral rigidity or bearing capacity without concrete shear wall. When the reinforced concrete frame-eccentric steel support composite structure system is used in the desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com