Connection method between cam and axle tube of jacket assembling cam shaft

A camshaft and cam technology, which is applied to valve devices, engine components, machines/engines, etc., can solve the problems of poor use effect, weak cam connection, short life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

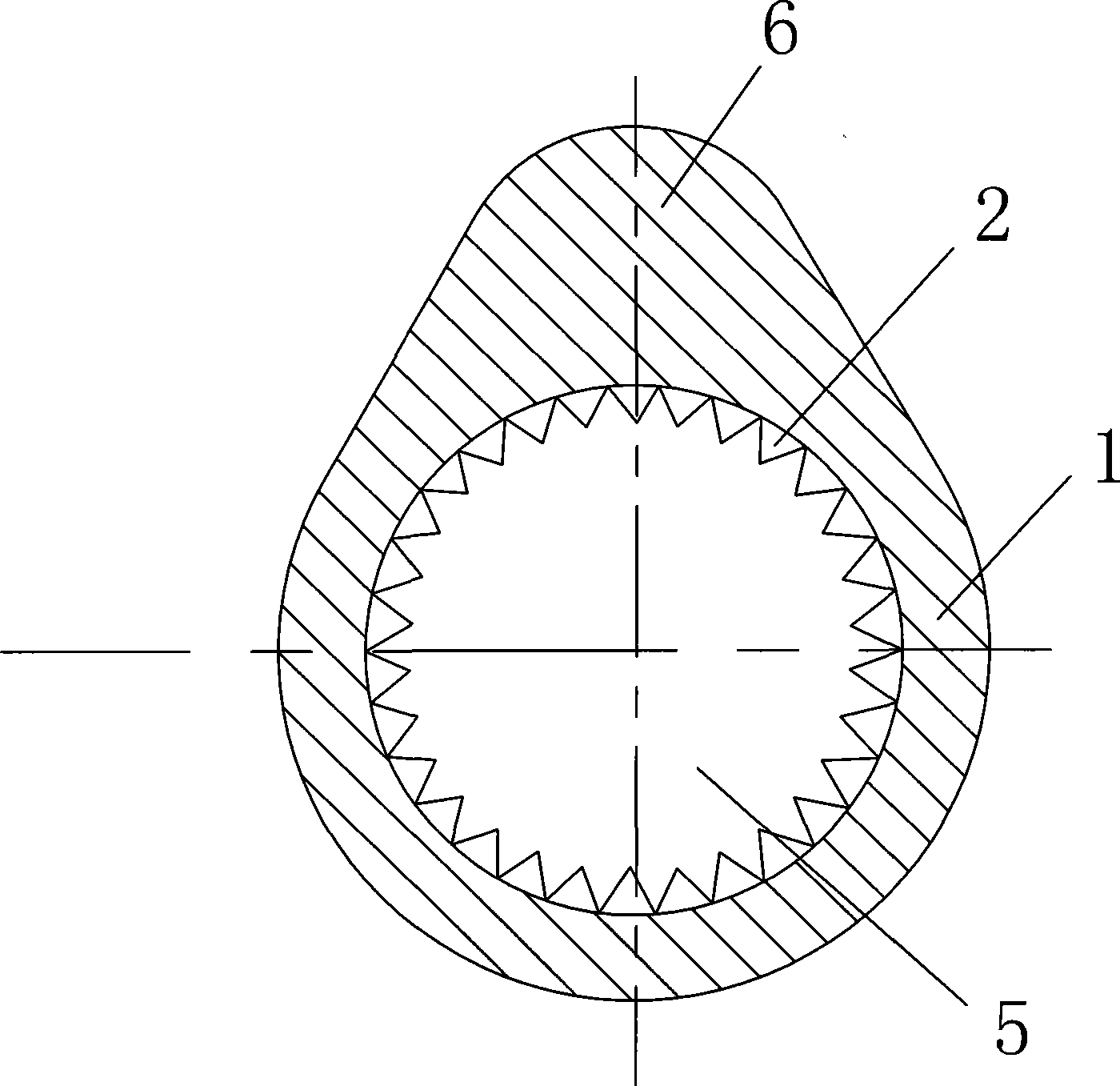

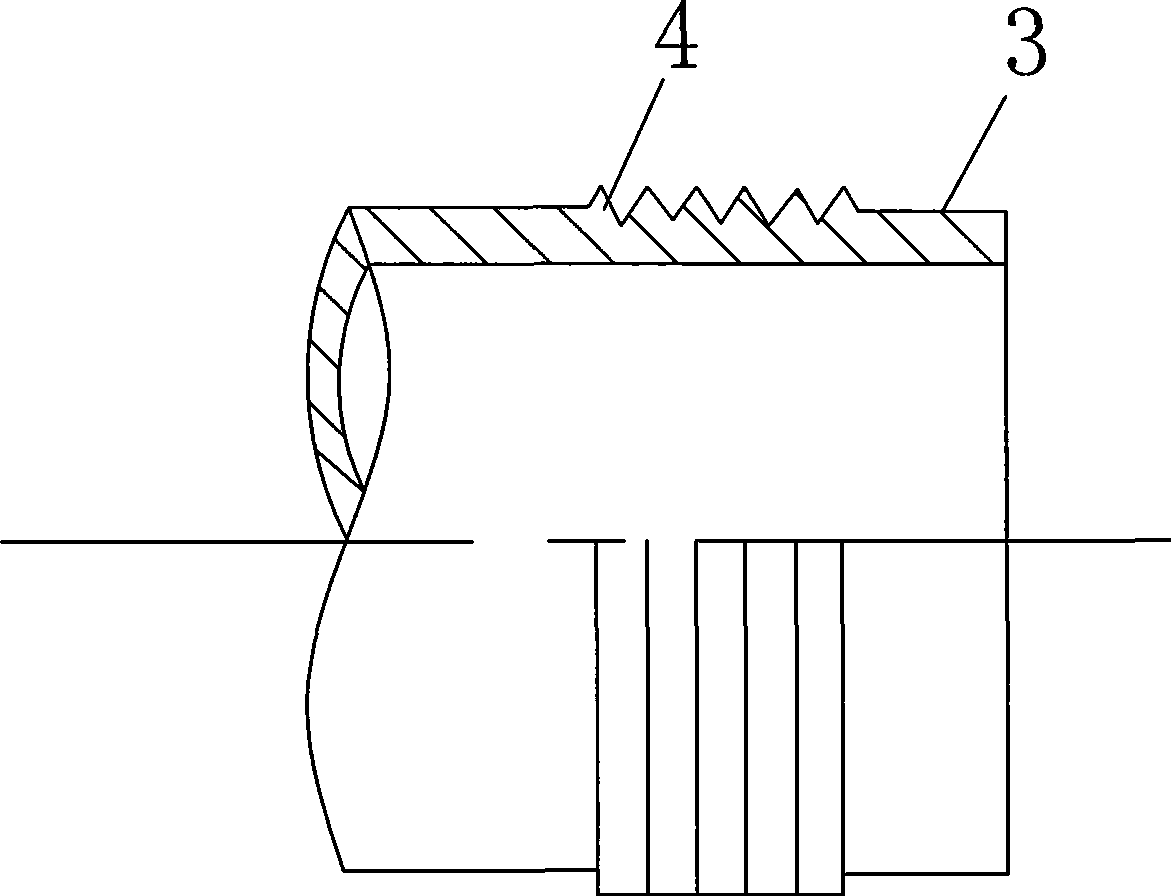

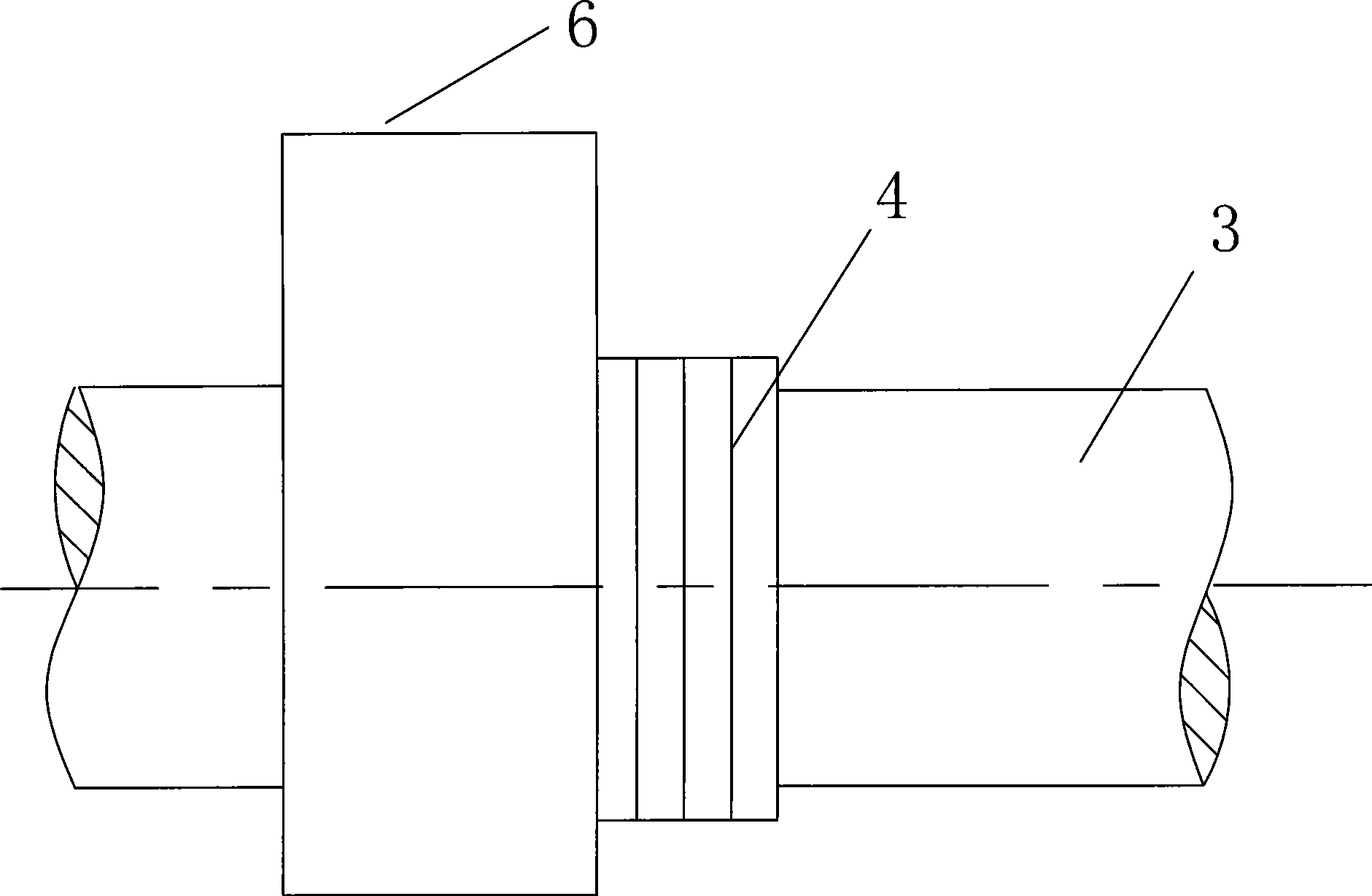

[0011] Example 1. In the actual production of the present invention, the cam 1 and the shaft tube can adopt the shrink-fit mechanical extrusion method. The specific steps are: first, straight grain knurling or teeth 2 are evenly processed on the surface of the inner hole 5 of the cam 1, and the straight grain knurling The flower or tooth modulus is 0.3-0.5, and then the outer surface of the shaft tube 3 is fitted with a cam, and the thread or annular groove 4 corresponding to the straight grain knurling or tooth 2 is evenly processed, and the thread or annular groove The groove 4 pitch is 0.8—2.0mm, and then the cam is heated to 150°C-300°C, and then the threads or annular grooves on the outer surface are pressure-fitted on the straight grain knurling or teeth on the surface of the inner hole of the cam , so that the threads or annular grooves 4 on the outer surface of the shaft tube 3 and the straight knurls or teeth on the surface of the inner hole of the cam intersect and en...

example 2

[0012] Example 2. In the actual production of the present invention, the cam 1 and the shaft tube can also adopt the internal expansion tooth embedding method. The steps are: firstly, the surface of the inner hole 5 of the cam 1 is uniformly processed with straight grain knurling or teeth 2, and then The outer surface of the shaft tube 3 is fitted with the cam, and the threads or annular grooves 4 corresponding to the straight grain knurling or teeth are uniformly processed, and then the threads or annular grooves 4 on the outer surface of the shaft tube are applied with internal high pressure (The pressure is determined according to the specifications and models of different products.) The shaft tube and the cam are expanded, and the straight knurling or teeth of the cam are firmly embedded in the outer surface of the shaft tube, so that the cam and the shaft tube are firmly connected.

[0013] The invention changes the traditional connection form in which the inner hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com