Diesel engine hand-operated actuating inversion proof device and matched start-up device

A starting device and diesel engine technology, which is applied in the field of diesel engine accessories, can solve the problems that the diesel engine cannot meet the industry standard of hand cranking, hurt people, and the starting handle is not held firmly, and solve the accident of starting and reversing hurting people. The structure is simple and reasonable, Good anti-reversal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

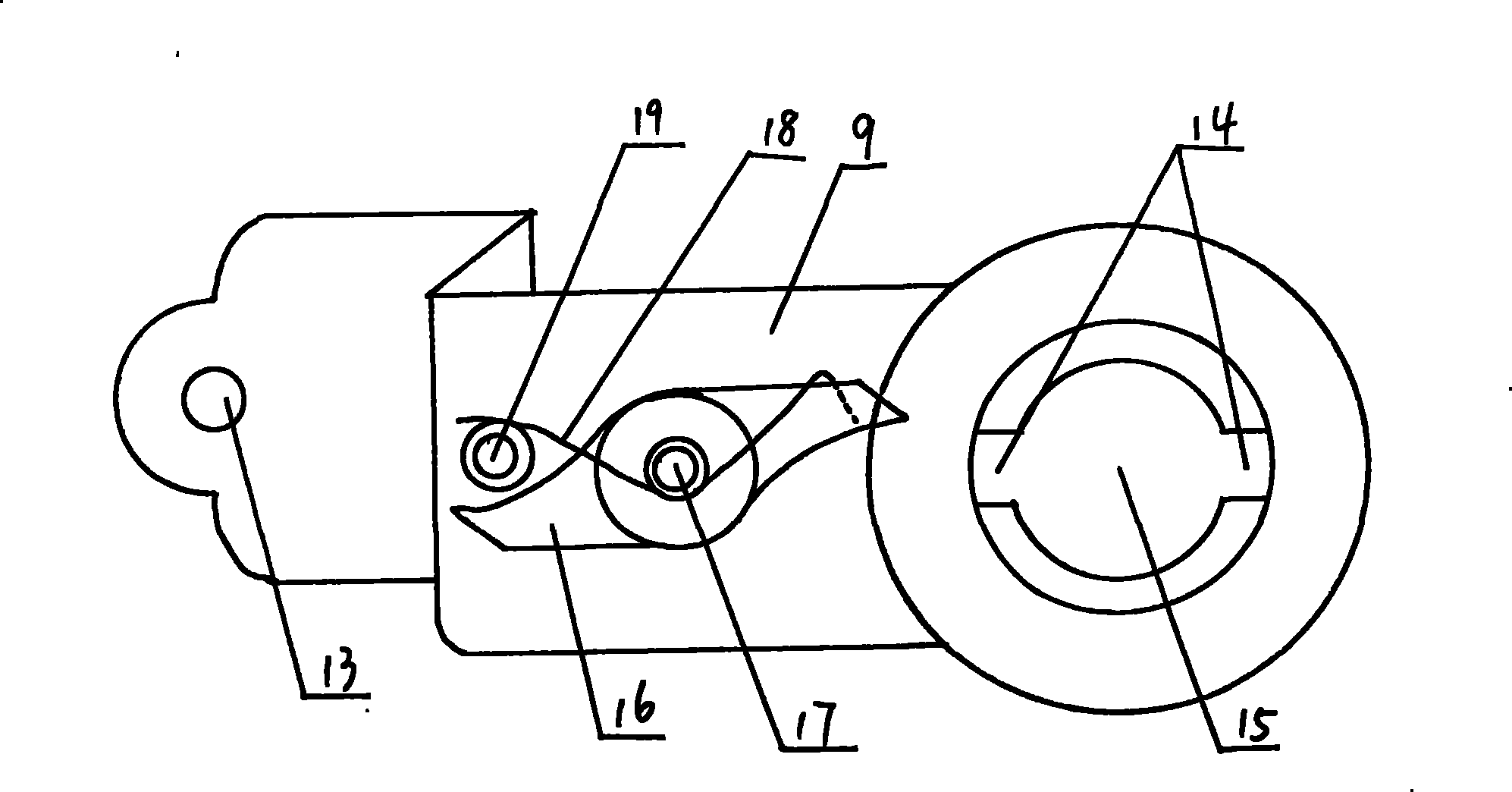

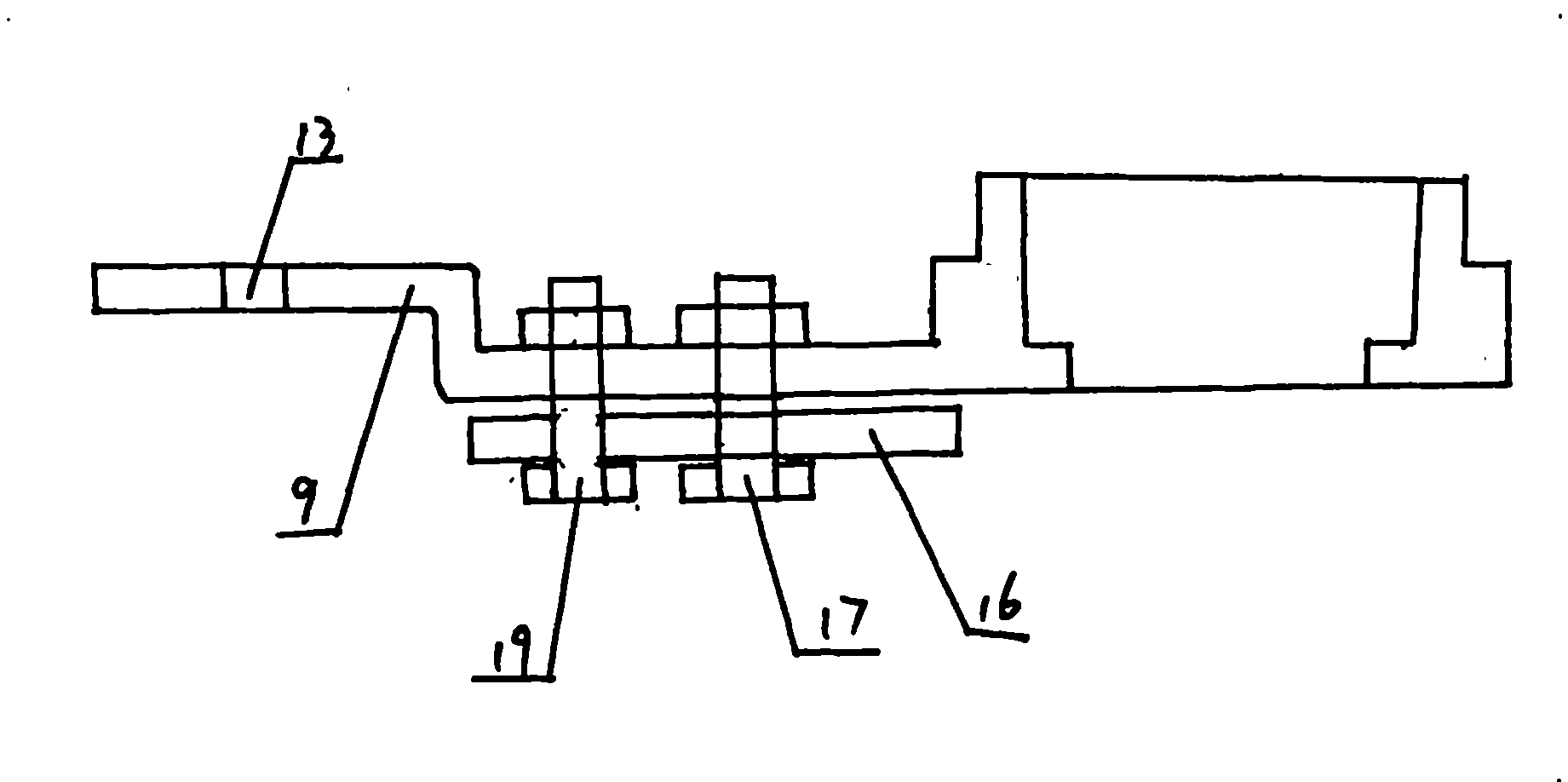

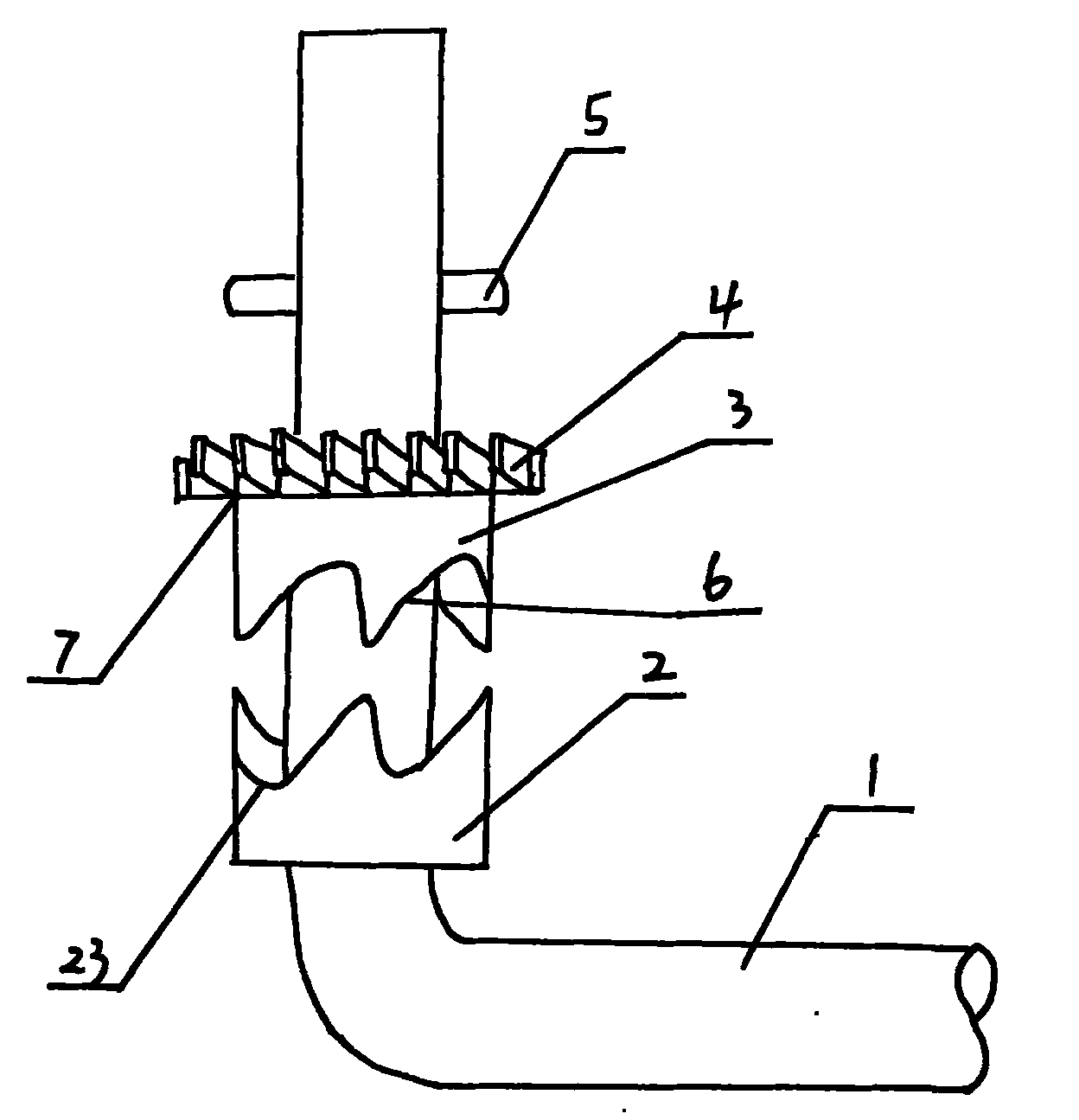

[0034] Example 1. refer to Figure 1-2 . An anti-reverse device for manual cranking of a diesel engine, which includes a pawl assembly 8 installed around the front side of the diesel engine starting shaft 10; the pawl assembly 8 is installed through a bracket 9 or directly installed on the diesel engine 11 The pawl assembly 8 is composed of a pawl 16, a positioning shaft 17, a reverse limit wire 19 and a pawl return spring 18. The pawl 16 is connected to the bracket 9 or the diesel engine 11 through the positioning shaft 17, and the reverse limit Wire 19 is arranged on the bracket 9 or the diesel engine 11 on the side of the pawl 16, and the pawl 16 rotates in one direction around the positioning shaft 17 under the limit of the reverse limit wire 19; one end of the pawl return spring 18 is fixed on the support 9 or on the diesel engine 11, the other end is located on the ratchet 16, and the ratchet 16 returns under the effect of the ratchet return spring 18.

Embodiment 2

[0035]Example 2. Refer to Figure 9. In the anti-reverse device described in Embodiment 1, there are two ratchet assemblies 8; the rear end of the ratchet 16 has the same structure as the front end.

Embodiment 3

[0036] Example 3. refer to Figure 1-2 ,9. In the anti-reversal device described in Embodiment 1, when the pawl assembly 8 is installed on the diesel engine 11 through the bracket 9, the bracket 9 is provided with a starting shaft hole corresponding to the starting shaft 10 of the diesel engine. The shaft hole is composed of a connected shaft hole 15 and two symmetrical pin shaft limiting holes 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com