Compact microchannel heat exchanger

A micro-channel heat exchanger, compact technology, applied in the field of condensers and compact micro-channel heat exchangers, to achieve the effect of reduced volume, no thermal resistance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

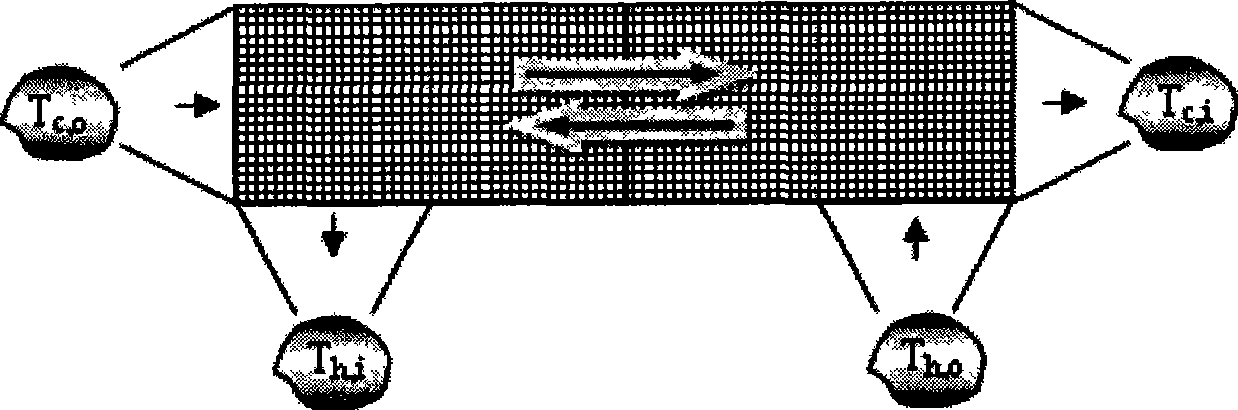

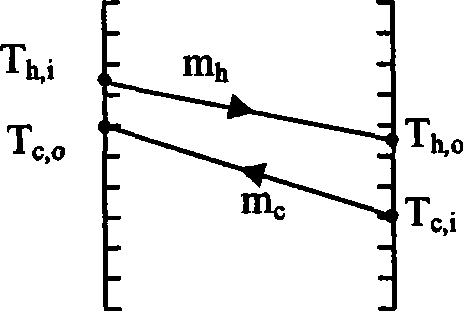

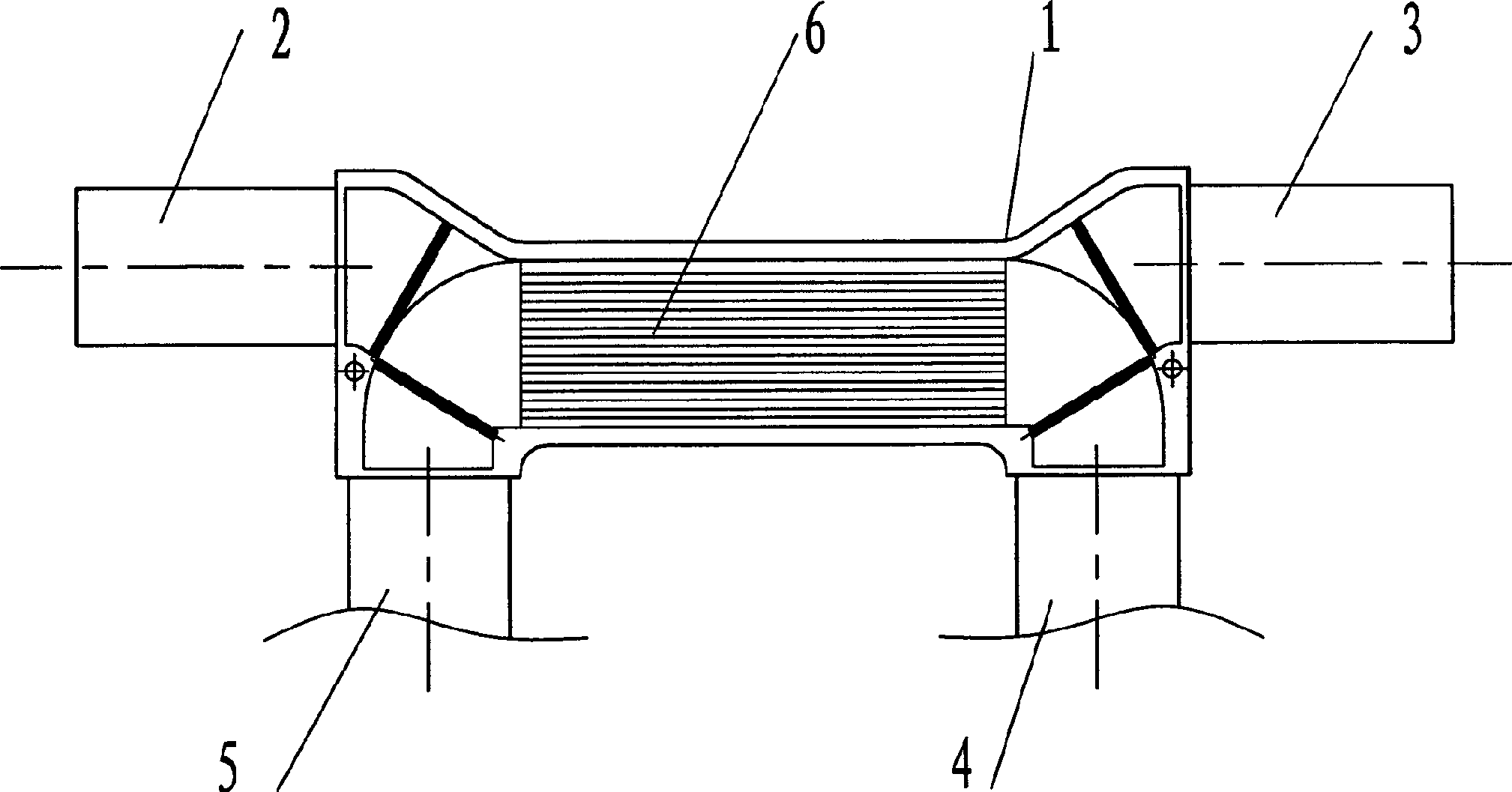

[0024] From image 3 and Figure 4 It can be seen from the figure that the compact microchannel heat exchanger of the present invention includes a housing 1, on which the high-temperature fluid inlets and outlets 2 and 3 and the low-temperature fluid inlets and outlets 4 and 5 are respectively set, It is characterized in that: the shell 1 is provided with a plurality of channels stacked up and down the micro channel 6, the single layer high temperature fluid channel 7 on the micro channel 6 communicates with the high temperature fluid inlet and outlet 2 and 3, its double Several layers of low-temperature fluid passages 8 communicate with the low-temperature fluid inlets and outlets 4 and 5, and there are partitions between the high-temperature fluid passages 7, between the low-temperature fluid passages 8, and between the high-temperature fluid passages 7 and the low-temperature fluid passages 8. layer.

[0025] After the high-temperature fluid (such as refrigerant) flows in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com