Liquid level sensor

A technology of liquid level sensor and Hall device, which is applied in the direction of buoy liquid level indicator, etc., can solve the problems of easy corrosion, circuit breakage, and difficult to greatly improve the service life, and achieve the effect of simplifying the processing circuit and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

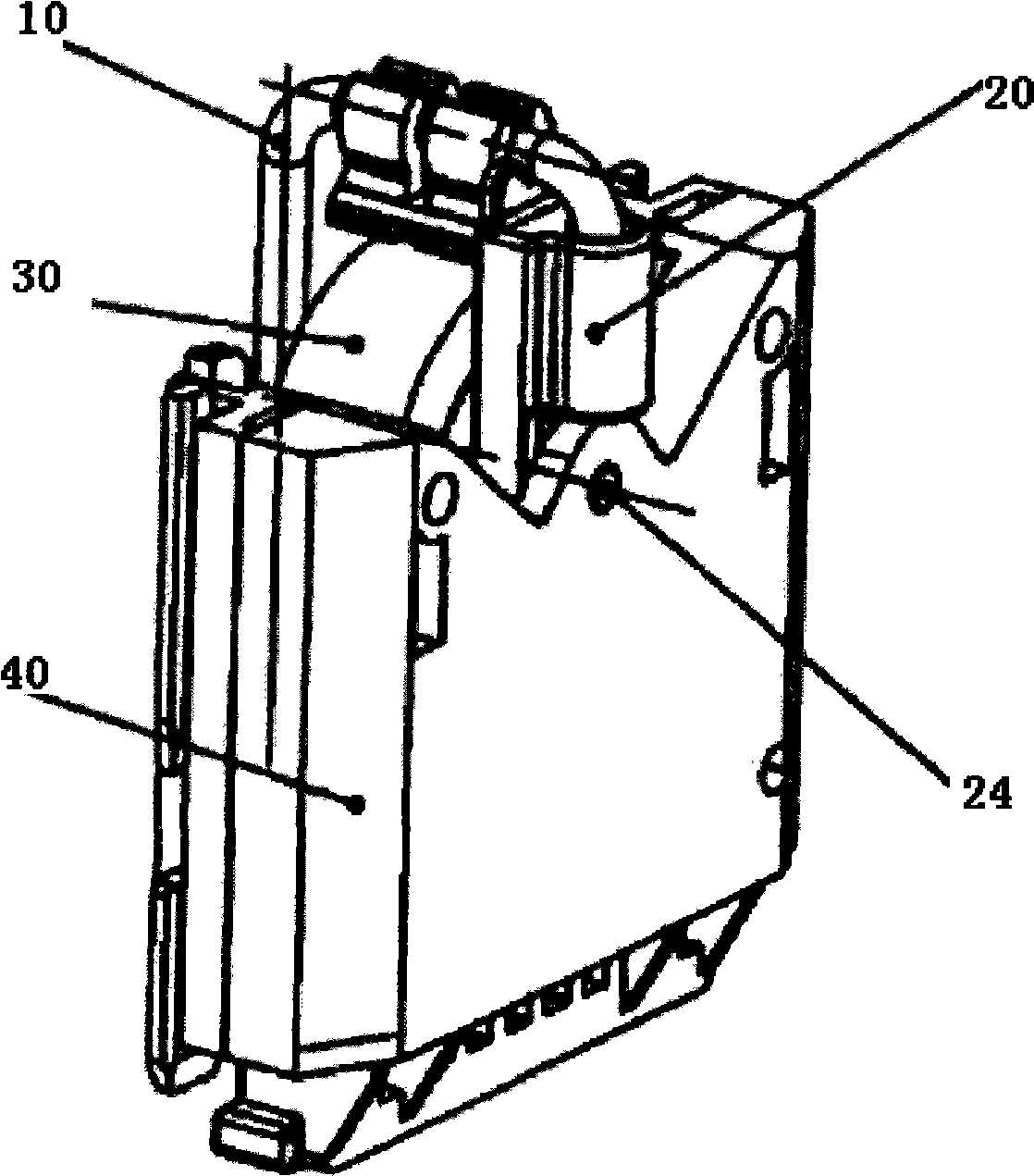

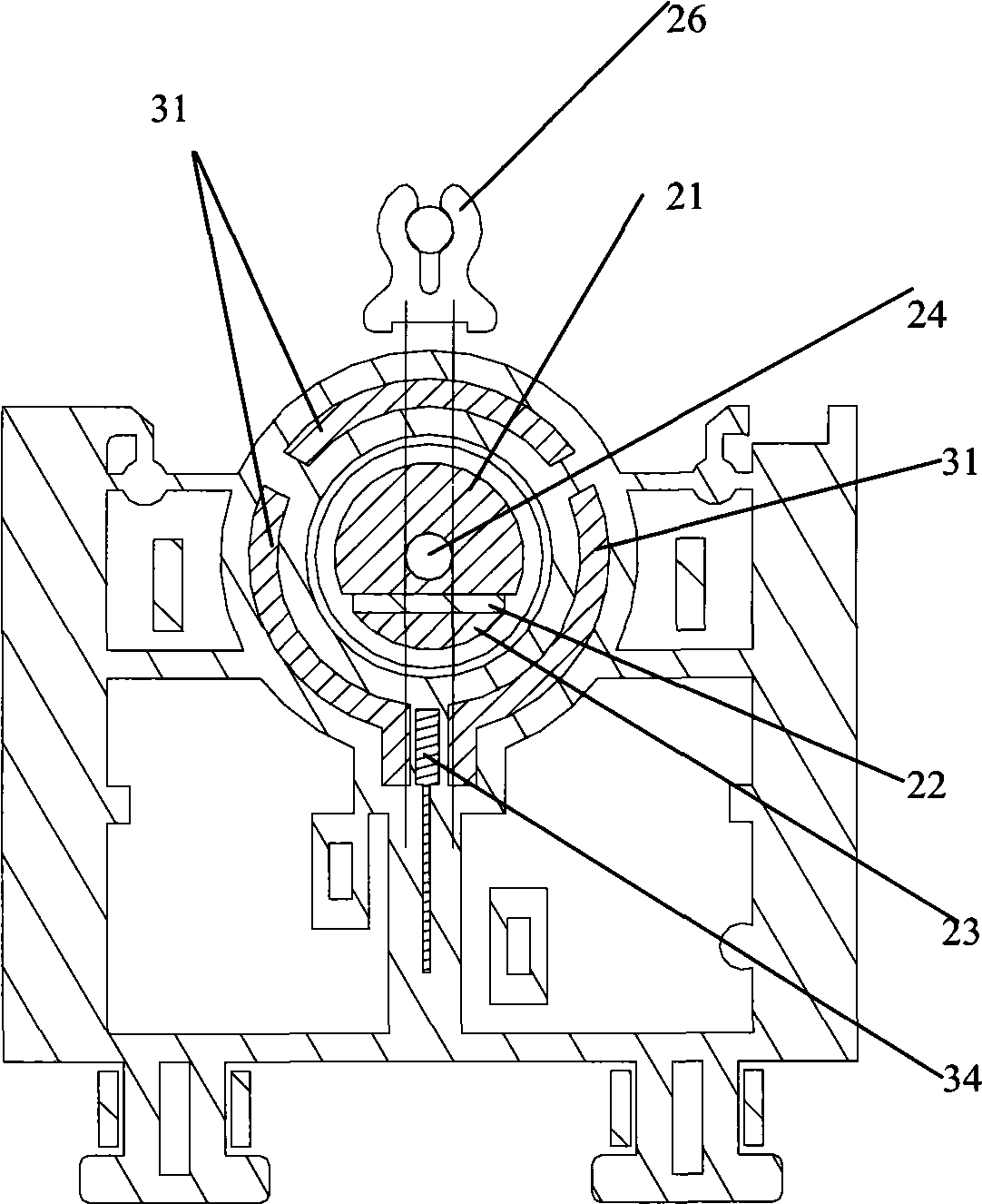

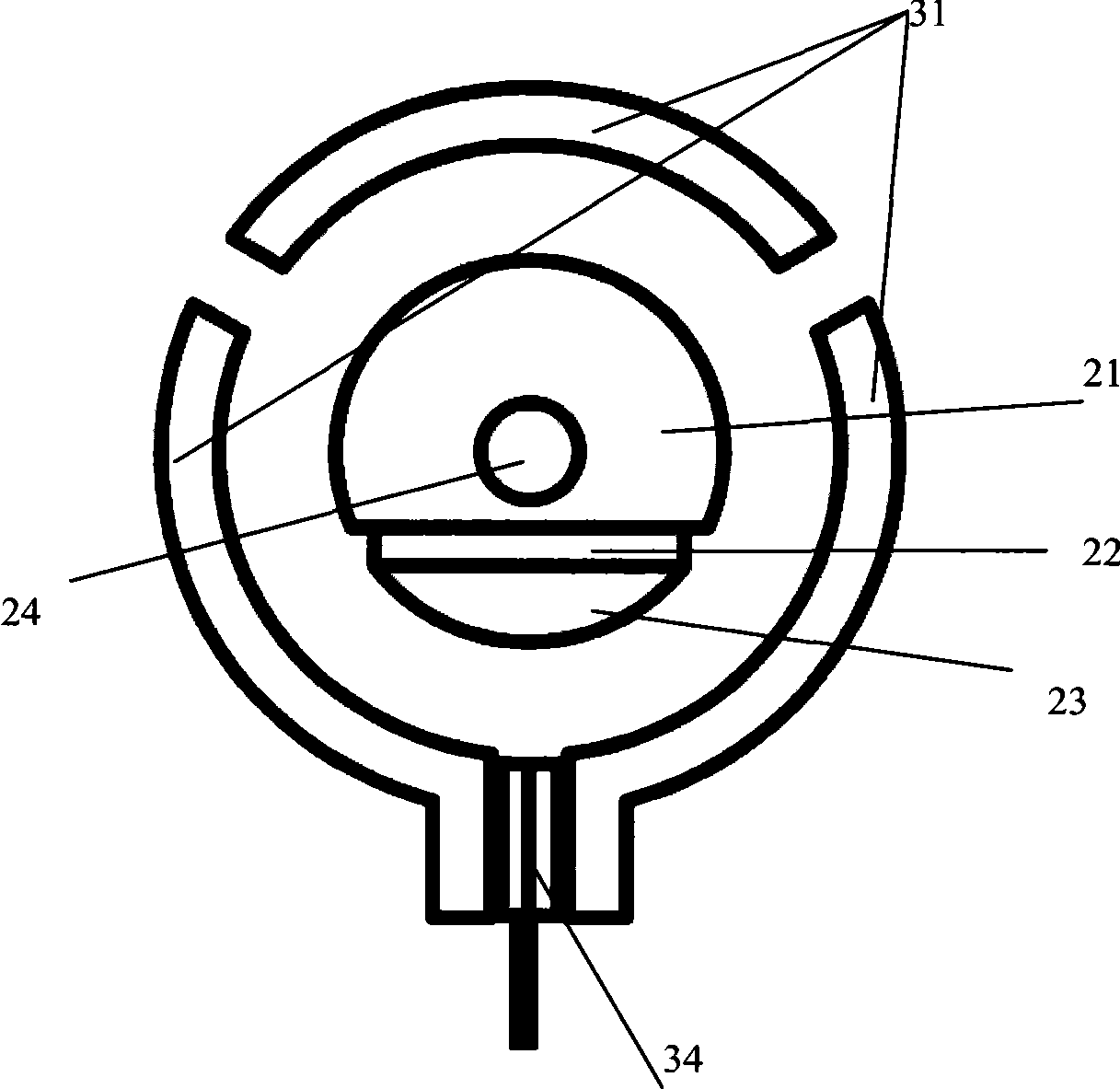

[0012] An embodiment of the liquid level sensor of the present invention is as follows: figure 1 , figure 2 As shown, it includes a rotor 20, a stator 30, a float assembly 10, and a side cover 40; the rotor is as figure 2 , image 3 As shown, it includes a support buckle 26, a rotary shaft 24, a larger soft iron one 21, a smaller soft iron two 23, a magnet 22, and a cylindrical plastic shell one. The magnet 22 is clamped on the soft iron Between iron one 21 and soft iron two 23, soft iron one 21, magnet 22, and soft iron two 23 form a cylinder together, and the axis of the cylinder formed together is provided with a circular hole one, and the soft iron one 21 exceeds Half of the cylinder formed together in the axial direction, the round hole one is set in the soft iron one 21, the rotary shaft 24 is sleeved in the round hole one, and the ends one and two end protrude out. The soft iron one 21, soft iron two 23, magnet 22 and the middle part of the rotary shaft 24 of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com